Low-emission PP material and preparation method thereof

A low-emission, anti-oxidant technology, applied in the chemical industry, can solve the problems of low surface tension, poor photoaging and heat aging performance, large shrinkage rate, etc., and achieve the effect of reducing odor and TVOC, high purity and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

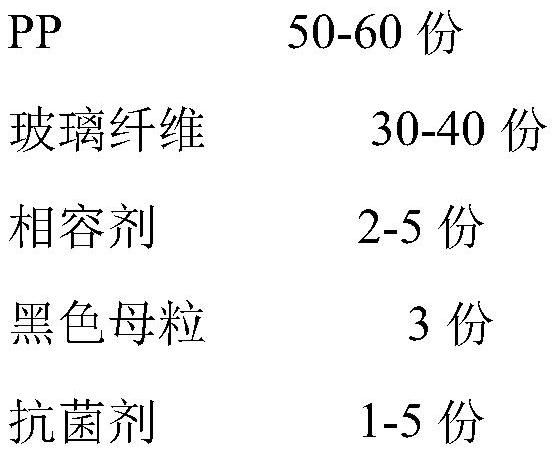

[0022] The components and parts by weight of the 100Kg material of the low emission PP material are: 50 parts by weight of PP material, 40 parts by weight of glass fiber, 2 parts by weight of compatibilizer, 5 parts by weight of antibacterial agent, and 3 parts by weight of black masterbatch With 0.2 parts by weight of antioxidant.

Embodiment 2

[0024] The components and parts by weight of the 100Kg material of the low emission PP material are: 60 parts by weight of PP material, 30 parts by weight of glass fiber, 2 parts by weight of compatibilizer, 5 parts by weight of antibacterial agent, and 3 parts by weight of black masterbatch With 0.2 parts by weight of antioxidant.

Embodiment 3

[0026] The components and parts by weight of the 100Kg material of the low emission PP material are: 57 parts by weight of PP material, 30 parts by weight of glass fiber, 5 parts by weight of compatibilizer, 5 parts by weight of antibacterial agent, and 3 parts by weight of black masterbatch With 0.2 parts by weight of antioxidant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com