Polyurethane foam system

A polyurethane and foam technology, applied in the field of foamed-in-place polyurethane foam systems, can solve the problems of a large number of catalysts, reduced emission behavior, and foam products that do not exhibit processing characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

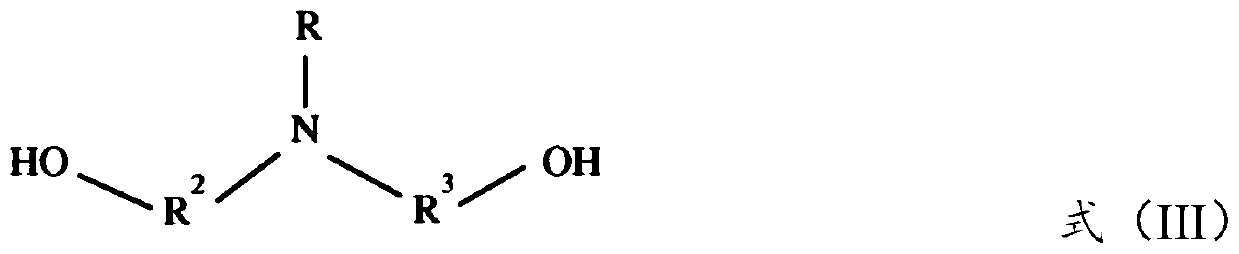

[0056] Of particular importance for the production of flexible foams are the reaction products of alkylene oxides, such as ethylene oxide and / or propylene oxide, with initiators containing 2 to 8, preferably 3 to 8, active hydrogen atoms per molecule . Suitable initiators include: polyols such as ethylene glycol, diethylene glycol, propylene glycol, dipropylene glycol, butylene glycol, glycerin, trimethylolpropane, triethanolamine, pentaerythritol, and sorbitol; polyamines such as ethylenediamine , toluenediamine, diaminodiphenylmethane, and polymethylenepolyphenylenepolyamine; and aminoalcohols, such as ethanolamine and diethanolamine; and mixtures of such initiators. Other suitable polyols include polyesters obtained by condensation of appropriate proportions of diols and higher functionality polyols with polycarboxylic acids. Still further suitable polyols include hydroxyl-terminated polythioethers, polyamides, polyesteramides, polycarbonates, polyacetals, polyolefins, pol...

example

[0098] The following examples are presented to further illustrate the invention, but are not to be construed as limiting the scope of the claims. All parts and percentages are by weight unless otherwise indicated.

[0099] Various terms and designations used in the examples are explained herein as follows.

[0100] VOC means volatile organic compound.

[0101] SPECFLEX* NC 138 is a glycerol initiated polyoxyethylene terminated polyoxypropylene polyol having an equivalent weight of approximately 2040, a nominal functionality of approximately 3.0, a percent polyoxyethylene capping of approximately 15%, and a hydroxyl number of approximately 28 ; and can be purchased from The Dow Chemical Company.

[0102] SPECFLEX NC 701 is a graft polyether polyol containing copolymerized styrene and acrylonitrile with an OH number of 19 to 25 mg KOH / g; and is commercially available from The Dow Chemical Company.

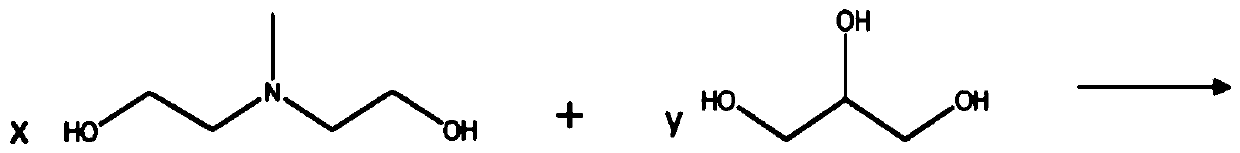

[0103] SPECFLEX ACTIV 2306 is an amine initiated autocatalytic polyether poly...

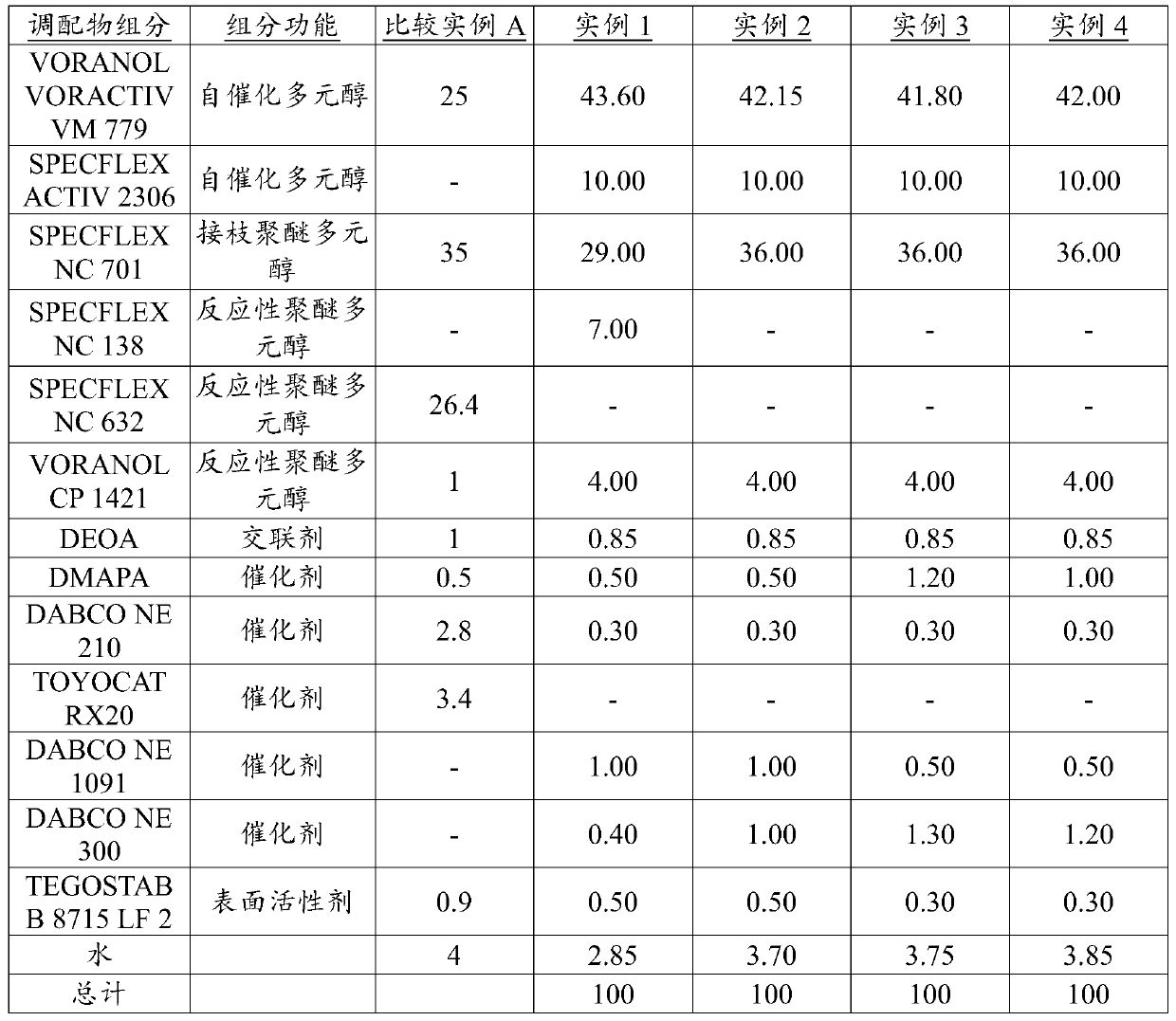

example 1- example 4 and comparative example A

[0118] The examples described in Table I include formulated polyol blends reacted with MDI. The MDI has the isocyanate content as described in Table I. The polyol blend (B side material) was mixed with the polymeric MDI (A side material) in a polyurethane dispenser. Such dispensing machines are commercially available as standard machines from equipment suppliers such as Henneke, KraussMaffei and Cannon. In the examples prepared as described in Table I, the formulations were subjected to the following processing conditions:

[0119] The dispenser is capable of mixing a given foam forming system at a given ratio of isocyanate to polyol. Ratio is controlled by pump / motor size. The dispensing temperature of the material is generally in the range of about 15°C to about 50°C. In the example, the temperature of the polymer T(poly) is 20°C; and the temperature of the isocyanate T(iso) is 20°C.

[0120] Dispensing pressures are typically in the range of about 100 bar to about 200 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com