Low-emission polypropylene reclaimed material and preparation method thereof

A polypropylene recycling and low-emission technology, which is applied in the field of low-emission polypropylene recycling and its preparation, can solve the problems affecting the emission performance and disadvantages of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

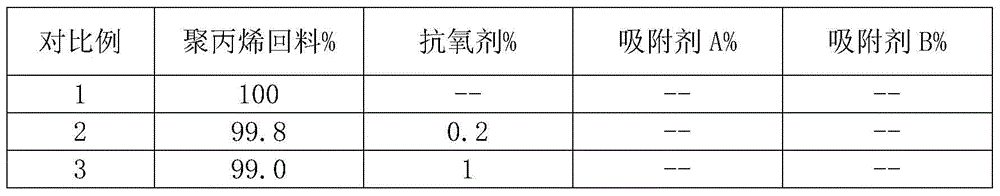

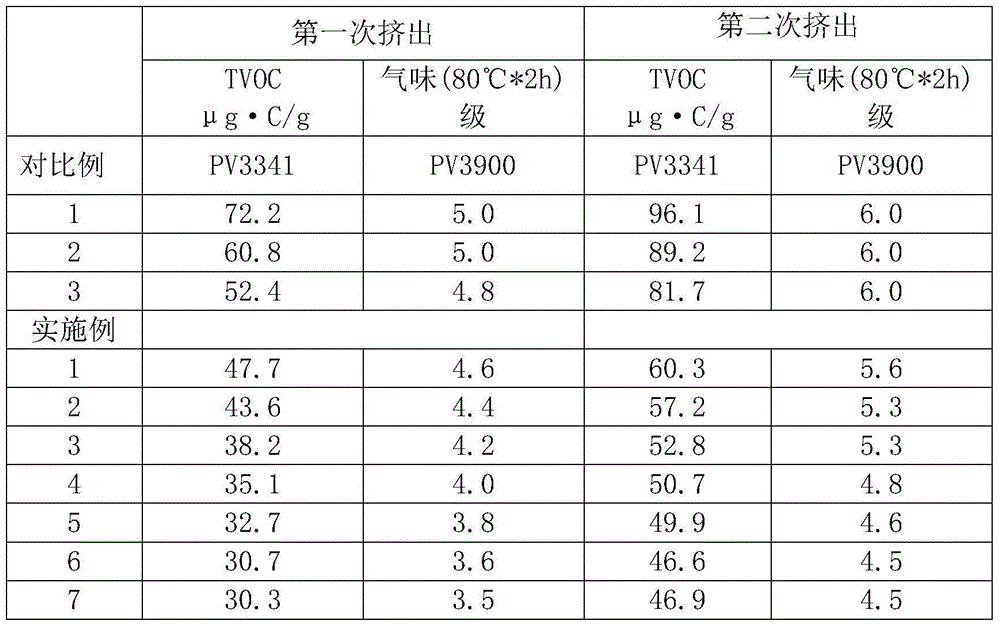

Examples

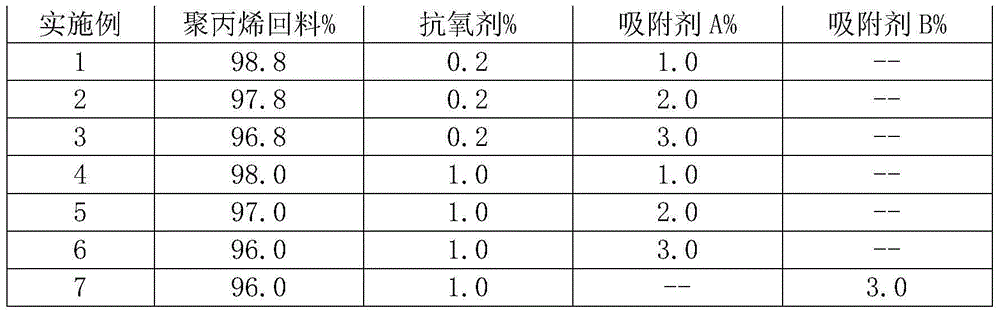

Embodiment 1

[0028] 98.8% of polypropylene, 0.2% of heat stabilizer, and 1.0% of adsorbent A are dry-mixed in a high-speed mixer for 3-5 minutes, and then melt-extruded in a twin-screw extruder and pelletized. The process is: 160-180℃ in the first zone, 200-210℃ in the second zone, 210-220℃ in the third zone, 210-220℃ in the fourth zone, 210-220℃ in the fifth zone, 205-215 in the sixth zone, 200-210 in the seventh zone, Pressure 12-18MPa.

Embodiment 2

[0030] 97.8% of polypropylene, 0.2% of heat stabilizer, and 2.0% of adsorbent A were dry mixed in a high-speed mixer for 3-5 minutes, and then melted and extruded in a twin-screw extruder to granulate. The process is: 160-180℃ in the first zone, 200-210℃ in the second zone, 210-220℃ in the third zone, 210-220℃ in the fourth zone, 210-220℃ in the fifth zone, 205-215 in the sixth zone, 200-210 in the seventh zone, Pressure 12-18MPa.

Embodiment 3

[0032] 96.8% of polypropylene, 0.2% of heat stabilizer, and 3.0% of adsorbent A were dry mixed in a high-speed mixer for 3-5 minutes, and then melted and extruded in a twin-screw extruder to granulate. The process is: 160-180℃ in the first zone, 200-210℃ in the second zone, 210-220℃ in the third zone, 210-220℃ in the fourth zone, 210-220℃ in the fifth zone, 205-215 in the sixth zone, 200-210 in the seventh zone, Pressure 12-18MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com