Low-odor spray-coating-free PC/ABS (polycarbonate/acrylonitrile butadiene styrene) material and preparation method thereof

An ABS material, spray-free technology, applied in the field of plastic blending modification, to achieve the effect of good appearance gloss, high blackness, good spray-free

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

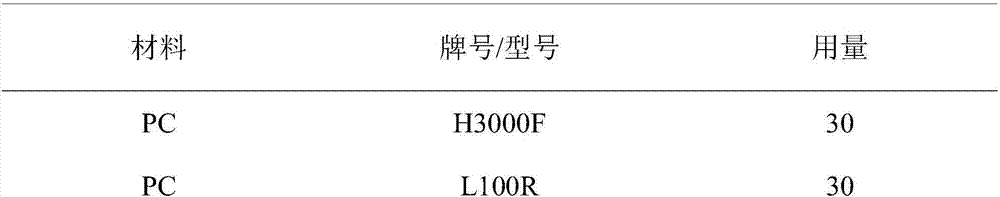

[0039] Among them, Table 1 is a list of component dosages of a low-odor spray-free PC / ABS material provided in Example 1 of the present invention.

[0040] PC: 40~80phr, ABS: 20~60phr, AS: 5~10phr, lubricant: 0~1phr, deodorant: 1~1.5phr, heat stabilizer: 0.5~1phr, masterbatch: 0.5~1phr, phase Compatibility agent: 0~10phr, processing aid: 0~5phr, antioxidant: 0.1~0.5phr, ultraviolet absorber: 0~5phr

[0041] Table 1. (Unit: phr)

[0042]

[0043]

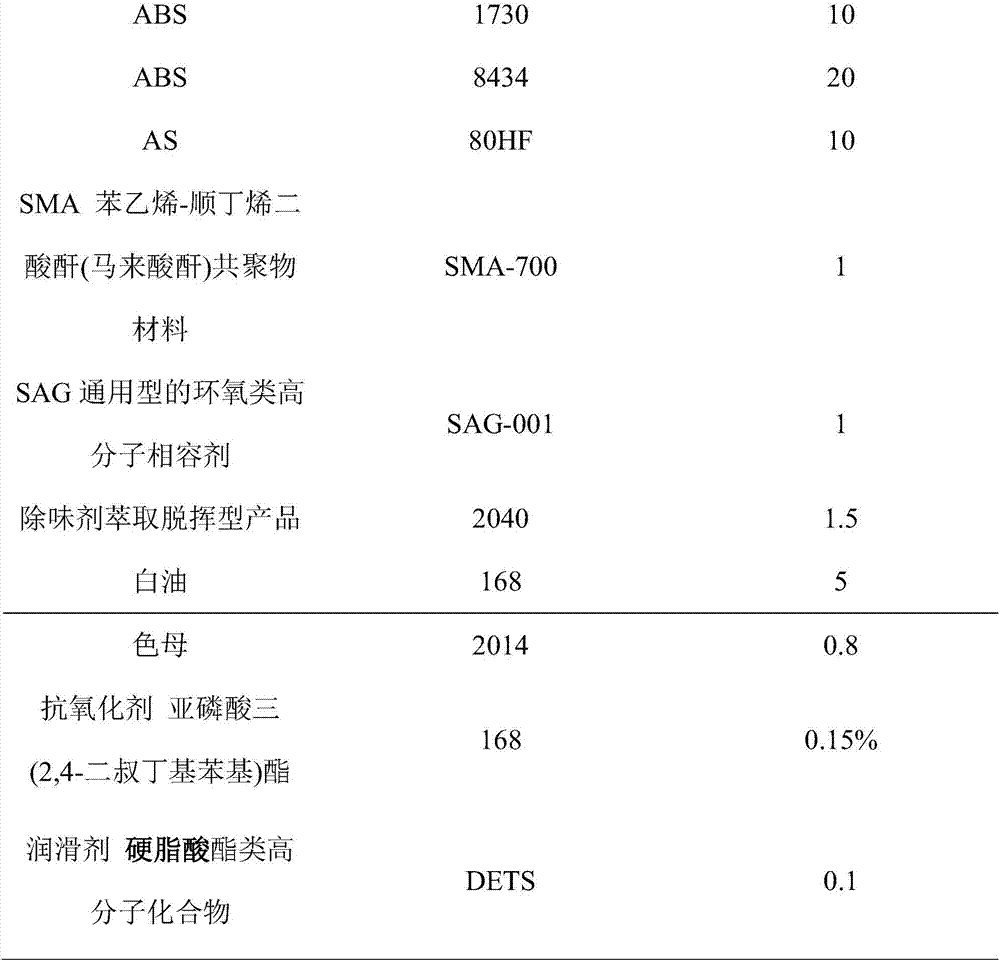

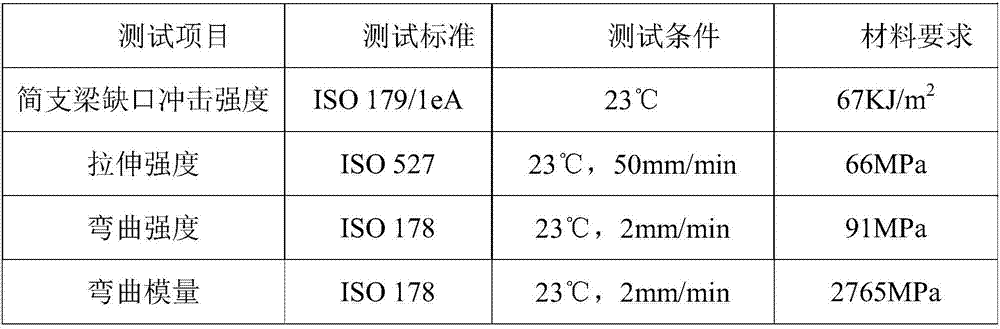

[0044] According to the above table, combined with the process route and process parameters, the product can be obtained. After drying and injection molding, the mechanical performance test data of the obtained low-odor spray-free PC / ABS material are shown in Table 2.

[0045]

[0046]

[0047] The retention rate of each index in Table 2 is above 90% as qualified.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com