Oyster shell powder reinforced 3D printing composite material and preparation method thereof

A technology of oyster shell powder and composite materials, which is applied in the direction of additive processing, climate sustainability, sustainable waste treatment, etc., can solve the problems of lack of photosensitive resin design scheme, poor strength and toughness, etc., and achieve good appearance gloss, Low cost, good for environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

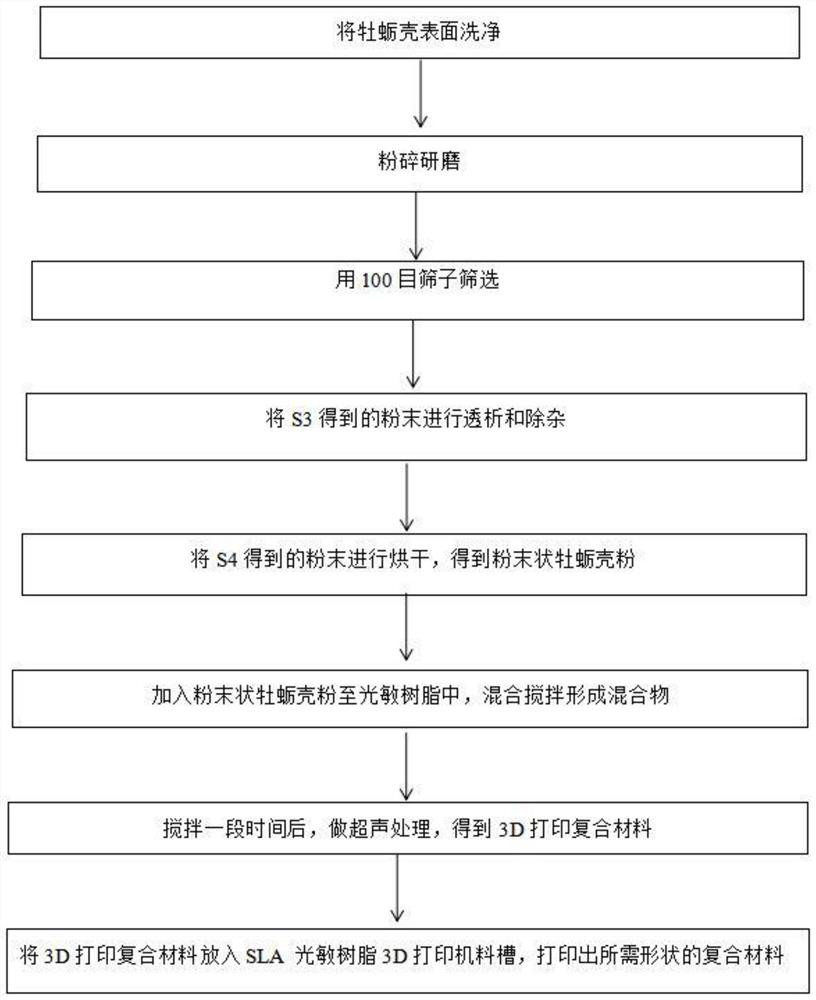

[0047] Please refer to figure 1 , this embodiment mainly introduces a preparation method of 3D printing composite material reinforced by oyster shell powder, which includes:

[0048] S1. Wash the surface of the oyster shell;

[0049] S2, crushing and grinding;

[0050] S3. Screen with a 100-mesh sieve;

[0051] S4, carry out dialysis and impurity removal with the powder obtained in S3;

[0052] S5, the powder obtained in S4 is dried to obtain powdered oyster shell powder;

[0053] S6, adding powdered oyster shell powder to the photosensitive resin, mixing and stirring to form a mixture;

[0054] S7. After stirring for a period of time, ultrasonic treatment is performed to obtain a 3D printing composite material;

[0055] S8. Put the 3D printing composite material into the SLA photosensitive resin 3D printing hopper.

[0056] Further, in the step S1, the surface of the oyster shell is washed with 1M HCl low-concentration hydrochloric acid.

[0057] Further, in the step S...

Embodiment 2

[0069] Based on the above-mentioned embodiment 1, this embodiment mainly introduces a method and results of testing the hardness of a 3D printing composite material reinforced by oyster shell powder using a Vickers hardness tester as follows:

[0070] S1. Preparation before the experiment

[0071] 1. Check the accuracy of the hardness tester: start it when the test piece is not installed, check the action of each mechanism, and then use the standard Vickers hardness block to check the indication accuracy;

[0072] 2. Preparation of the sample: the surface of the sample should be smooth, and the surface of the sample must be smooth in the production of the sample;

[0073] 3. Selection of test bench: It can ensure that the test piece is placed on it stably, and the surface is perpendicular to the indenter;

[0074] 4. Selection of test force: The test force is selected according to the thickness of the specimen, the expected hardness and the depth of the hardened layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com