BMC formula for manufacturing kitchen and bath supplies

A product, kitchen and bathroom technology, applied in the field of BMC formula for manufacturing kitchen and bathroom products and its preparation, can solve the problems of bulky products, insufficient surface adhesion, long production cycle, etc., to improve the overall strength and quality, and improve the appearance gloss. , the effect of solving the inefficiency problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further specifically described below through examples.

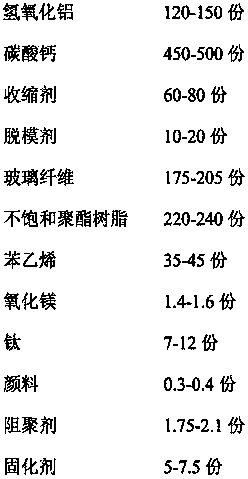

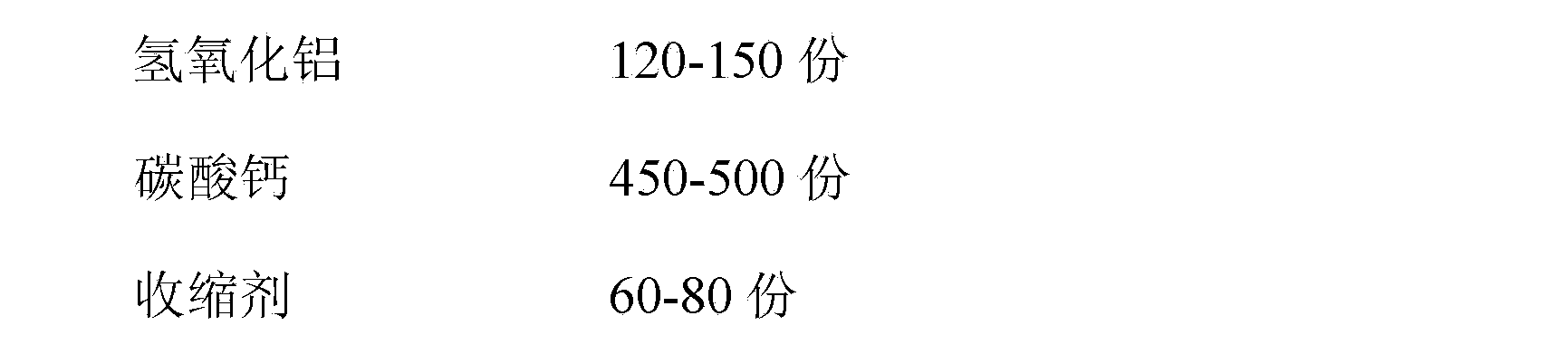

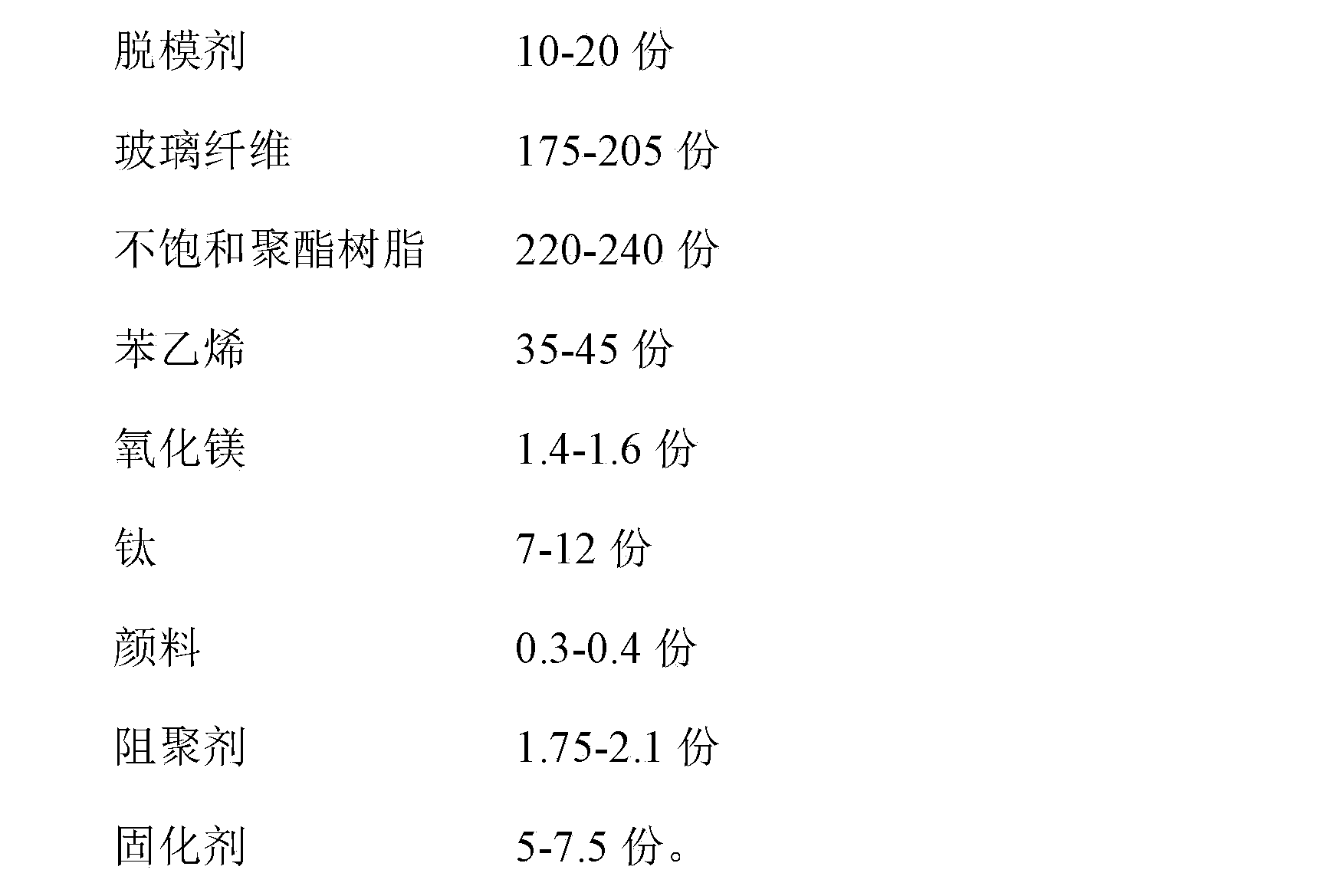

[0017] The present invention is a kind of BMC formulation for manufacturing kitchen and sanitary products, which is mainly composed of the following components by weight ratio:

[0018]

[0019] The specific process steps for manufacturing kitchen and bathroom products are as follows: All the synthetic raw materials including various types of unsaturated polyester resins, fillers, glass fibers and other additives are firstly stirred and kneaded with a mixer and kneader, and then molded, injected or transferred Molded into a variety of kitchen and bathroom products, and finally packaged and trimmed to complete the entire process.

[0020] The BMC thermosetting material composed of a specific formula in the present invention is molded, injected or transfer molded into various kitchen and bathroom products by mechanized and automated equipment, which improve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com