A kind of polyamide composite material for gas-assisted molding and its preparation method and application

A composite material and gas-assisted molding technology, which is applied in the field of polyamide composite materials, can solve the problems of reduced appearance gloss and unsatisfactory injection, and achieve the effects of easy operation and implementation, improved gloss, and large-scale promotion and application in the market

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

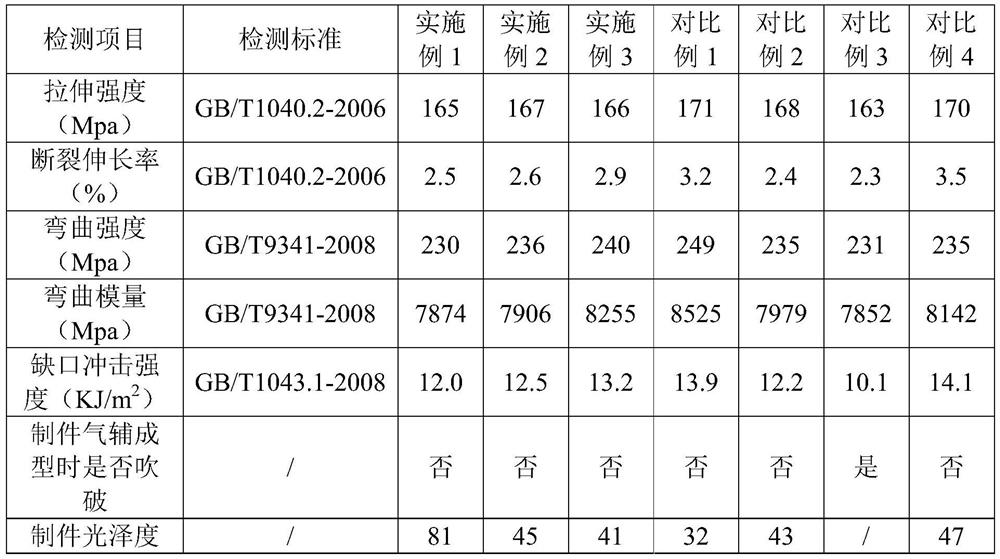

Examples

Embodiment 1

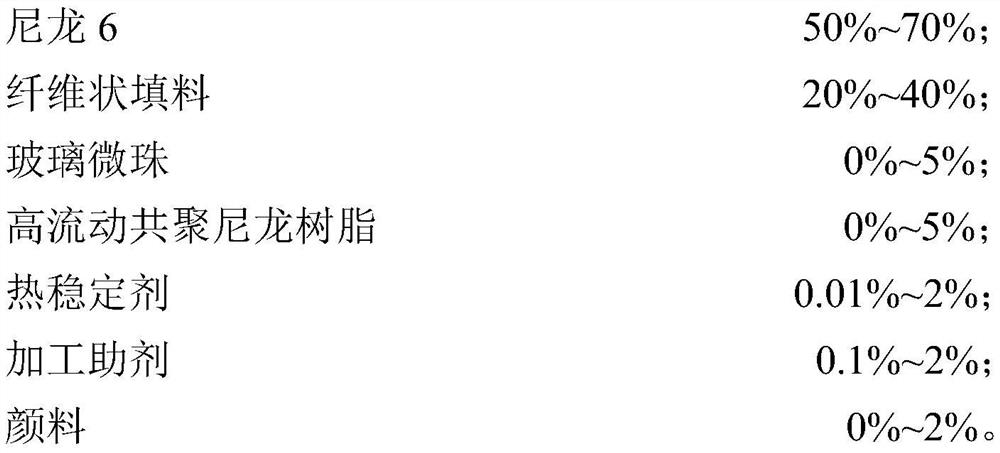

[0031]The polyamide composites use the following weight percent raw materials:

[0032]58% nylon 6 (nylon 6), a relative viscosity of 3.2, 30% fibrous filler (no alkali fiberglass 435N, Taishan glass fiber plant, is modified by silane coupling agent) The alkali-free glass fiber, the fiber diameter is 10 ~ 15μm), 5% glass microbead (050-20-215 French SOVITEC), 5% high flow co-polynone resin (melt index 150g / 10min, 200 ° C / 1.2kg, Zhuzhou era New materials), 0.2% heat stabilizers (leading HS02, mixture composed of copper and potassium from 1: 8), a mixture of potassium iodide, calcium stearate (calcium stearate), 1% pigment (black Mother 3785, Cabot Company).

[0033]Add nylon 6, high flow co-agglon resin, heat stabilizer, processing aid, and pigment to high-speed mixer 3000 rpm to add two-screw extruder from the main feedab to the main feedab to add the fibrous filler and glass microbead In the side feed hopper, in the twin screw extruder, the polyamide composite is obtained after extru...

Embodiment 2

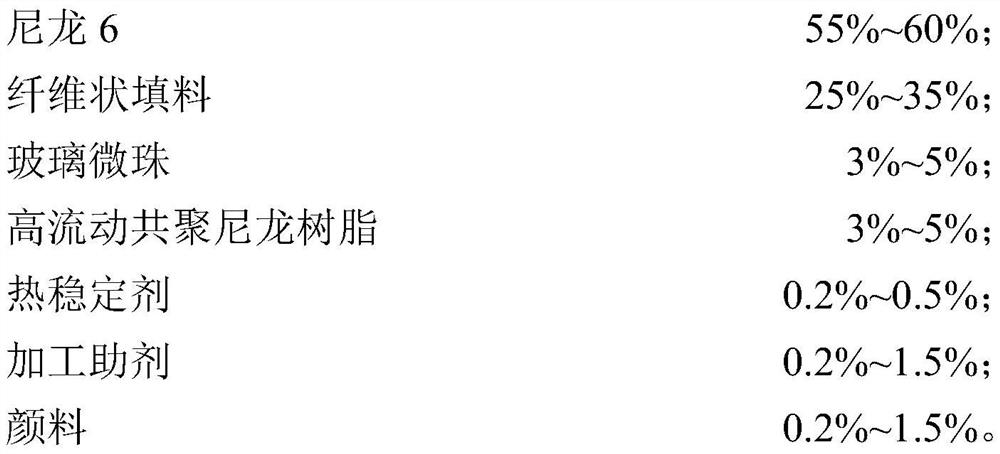

[0036]The polyamide composites use the following weight percent raw materials:

[0037]63% nylon 6 (new Meida, a number of nylon 6), relative viscosity of 3.2), 30% fibrous filler (unique base glass fiber 435N, Taishan glass fiber plant, adopted surface via silane coupling agent modified The alkali-free glass fiber, the diameter of the fiber is 10 ~ 15μm), 5% glass microbead (050-20-215 France SOVITEC), 0.2% heat stabilizer (US leading HS02, is from 1: 8 iodide of 1: 8) Mixtures of potassium iodide), 0.8% processing auxiliaries (calcium stearate), 1% pigment (black mother 3785, Carbot).

[0038]Add nylon 6, heat stabilizers, processing aids and pigments to high-speed mixer 3000 rpm to mix 1min after 1min, add double screw extruders from the main feed, and add fibrous filler and glass beads from the side feed bracket. In the screw extruder, the polyamide composite is obtained after extruding the double screw extruder.

[0039]The temperature setting of 265 ° C, 270 ° C, 265 ° C, 260 ° C, 250 ...

Embodiment 3

[0041]The polyamide composites use the following weight percent raw materials:

[0042]63% nylon 6 (new Meida, a number of nylon 6), relative viscosity of 3.2), 30% fibrous filler (unique base glass fiber 435N, Taishan glass fiber plant, adopted surface via silane coupling agent modified The alkali-free glass fiber, the diameter of the fiber is 10 ~ 15 μm), 5% high flow co-gaunon resin (melt index 150g / 10 min, 200 ° C / 1.2kg, Zhuzhou era new material), 0.2% heat stabilizer (US leading HS02, by Mixtures of the mass ratio of 1: 8 copper and potassium iodide), 0.8% processing auxiliaries (calcium stearate), 1% pigment (black mother 3785, Cabt).

[0043]The nylon 6, high flow co-aggregon resin, heat stabilizer, processing aids and pigments were added to 3000 rpm in a high-speed mixture for 1 min and added a double screw extruder from the main feedab to the double screw extruder, and fed the fibrous filler from the side feed In the double screw extruder, the polyamide composite is obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com