Polyethylene material resistant to electron beam irradiation as well as preparation and application thereof

A technology of electron beam irradiation and polyethylene, which is applied in the field of polyethylene materials, can solve the problems of reduced light transmittance, decreased mechanical properties, and yellow color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

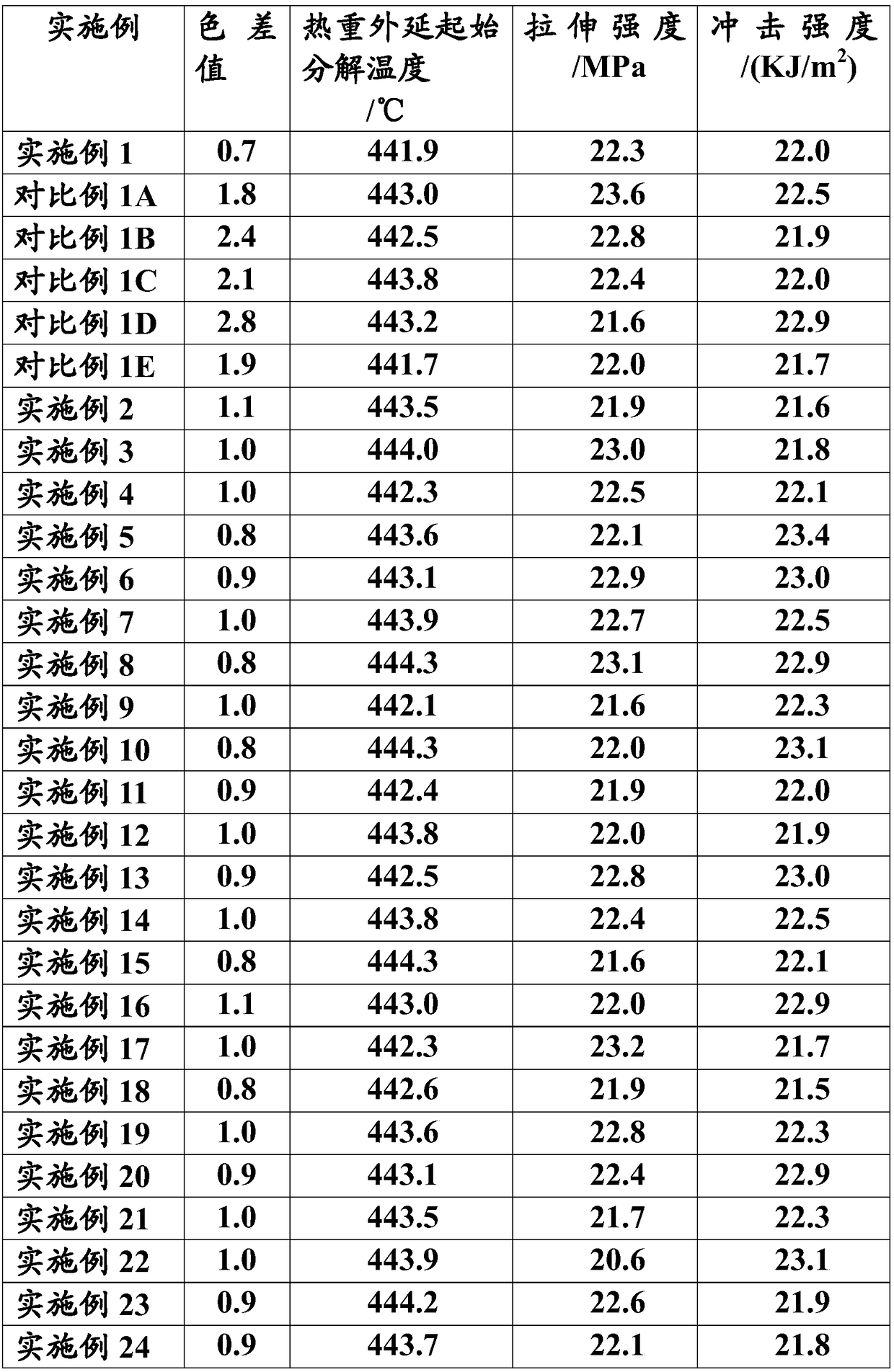

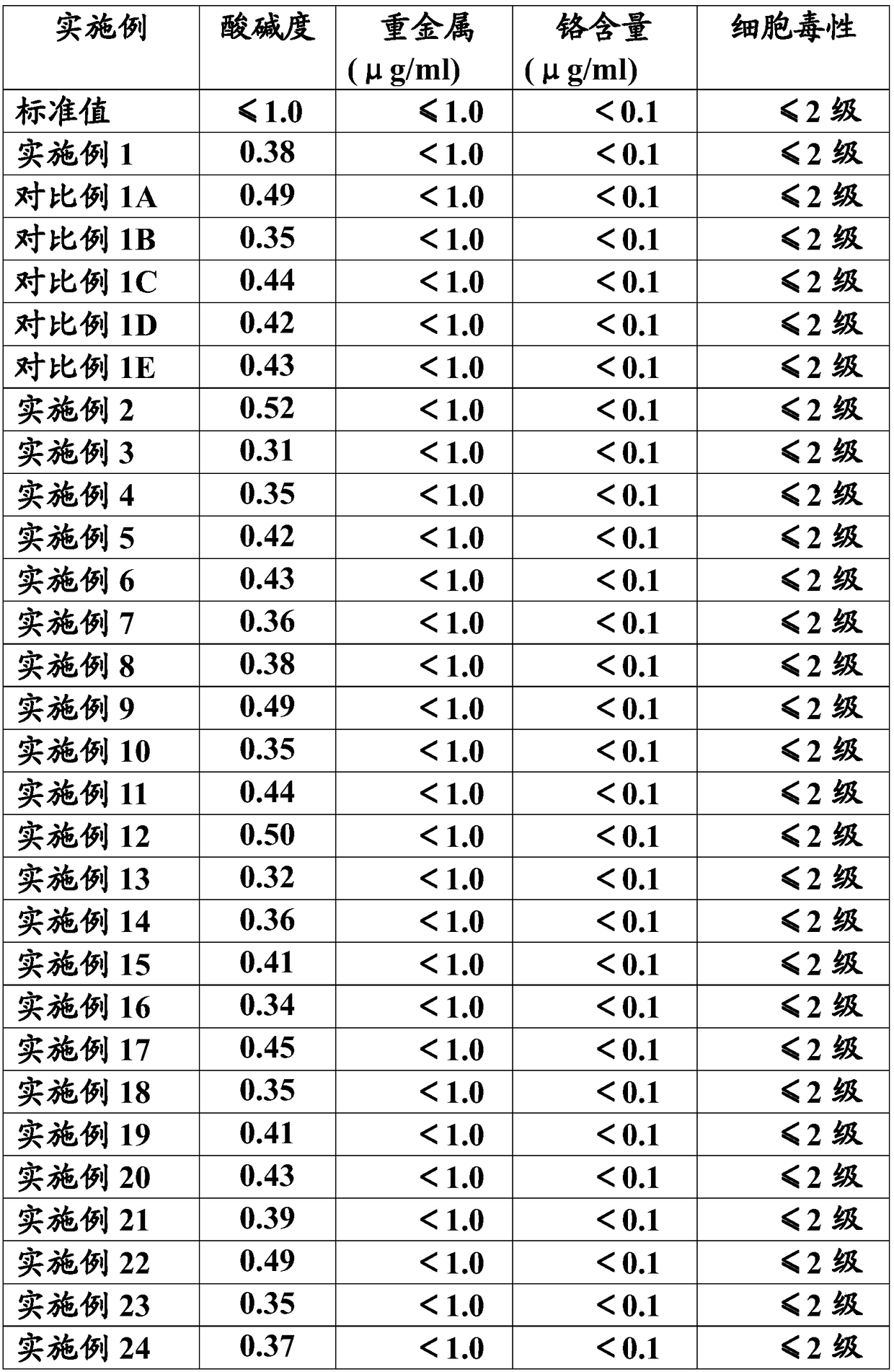

[0089] 100 parts by weight of polyethylene (2426H produced by China Petroleum Lanzhou Petrochemical Company) and 5 parts of primary antioxidant 1098 (BASF China Co., Ltd.), 5 parts of auxiliary antioxidant 626 (BASF China Co., Ltd.), 5 parts of light stabilizer 944 (BASF China Co., Ltd.), 5 parts of ultraviolet absorber UV-531 (BASF China Co., Ltd.) and 5 parts of light shielding agent titanium dioxide are blended, and melted and extruded at a temperature of 150°C-200°C through an extruder. The sample is obtained after injection molding by the injection molding machine. The sample has two sizes, namely a dumbbell-shaped sample of 10*4mm and a rectangular sample of 80*10*4mm. Firstly, the sample is irradiated with electron beam, and the irradiation dose is 25kGy, and then the performance test is carried out on the sample.

[0090] The test results of each experiment are shown in Table 1 and Table 2.

Embodiment 2

[0107] Repeat Example 1, except that the 2426H type polyethylene is replaced by the 2420F type polyethylene produced by Daqing Petrochemical.

[0108] The test results of each experiment are shown in Table 1 and Table 2.

Embodiment 3

[0110] Repeat Example 1, the difference is: the main antioxidant 1098 is replaced by the main antioxidant 1010.

[0111] The test results of each experiment are shown in Table 1 and Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com