Water-boiling-resistant and flame-retardant polypropylene composite material with high glow-wire ignition temperature and preparation method

A technology of flame-retardant polypropylene and high glow wire, which is applied in the field of polymers, can solve the problems of easy precipitation and low ignition temperature of glow wire, and achieve excellent anti-thermal oxygen aging and discoloration performance, reduce combustion heat release, and chain movement good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

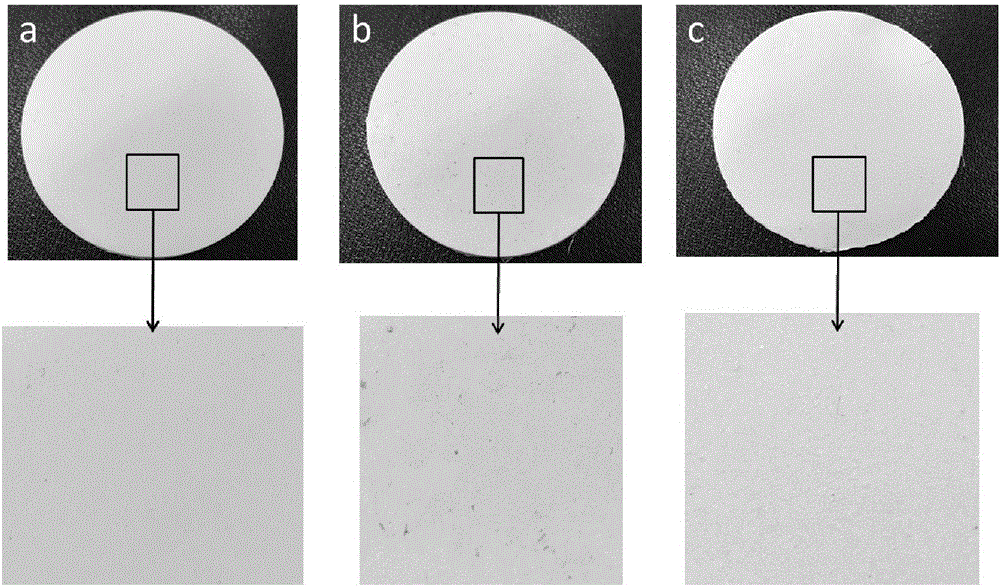

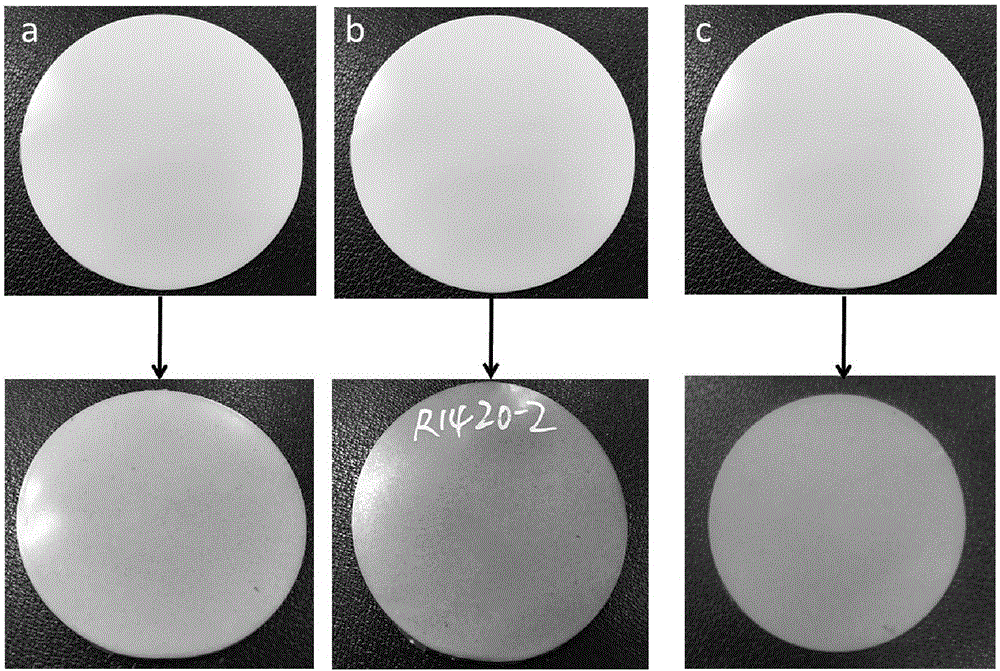

Image

Examples

Embodiment 1

[0031] The high-glow wire, boiling-resistant and flame-retardant polypropylene composite material in this embodiment is composed of the following raw materials by weight:

[0032]

[0033] Concrete preparation method comprises the following steps:

[0034] (1) 72 parts of isotactic homopolypropylene, 28 parts of self-prepared intumescent halogen-free flame retardant (23.3 parts of ammonium polyphosphate and 4.7 parts of triazine char-forming agent), 0.1 part of PTFE anti-dripping agent, 0.1 Part of hindered phenolic antioxidant, 0.1 part of phosphite antioxidant, 0.2 part of PE wax, 0.2 part of bright lubricant, 0.1 part of octaphenyl cage polysilsesquioxane are added to the mixer with nitrogen protection Mix on medium-high speed for 10 minutes;

[0035] (2) Under the protection of nitrogen, put the mixed material of (1) into a parallel twin-screw extruder to melt, extrude and granulate to obtain a reinforced polypropylene composite material; wherein the temperature of eac...

Embodiment 2

[0037] The high-glow wire, boiling-resistant and flame-retardant polypropylene composite material in this embodiment is composed of the following raw materials by weight:

[0038]

[0039] Concrete preparation method comprises the following steps:

[0040] (1) 50 parts of isotactic homopolypropylene, 25 parts of random copolymerized polypropylene, 25 parts of self-prepared intumescent halogen-free flame retardant (20.8 parts of ammonium polyphosphate and 4.2 parts of triazine char-forming agent), 0.15 Part of PTFE anti-dripping agent, 0.15 part of hindered phenolic antioxidant, 0.1 part of phosphite antioxidant, 0.25 part of PE wax, 0.25 part of bright lubricant, 0.15 part of octaphenyl cage polysilsesquioxane Add to a mixer with nitrogen protection and mix at high speed for 10 minutes;

[0041] (2) Under the protection of nitrogen, put the mixed material of (1) into a parallel twin-screw extruder to melt, extrude and granulate to obtain a reinforced polypropylene composit...

Embodiment 3

[0043] The high-glow wire, boiling-resistant and flame-retardant polypropylene composite material in this example is composed of the following raw materials in parts by weight, wherein ammonium polyphosphate (APP): triazine char-forming agent is compounded at a mass ratio of 5:1:

[0044]

[0045]

[0046] Concrete preparation method comprises the following steps:

[0047] (1) Add 20 parts of ammonium polyphosphate and 4 parts of triazine char-forming agent into a high-speed stirrer and stir for 5 minutes.

[0048](2) The above 24 parts of compound, 76 parts of isotactic homopolypropylene, 0.2 part of PTFE anti-dripping agent, 0.15 part of hindered phenolic antioxidant, 0.15 part of phosphite antioxidant, 0.3 part of PE Add wax, 0.3 parts of bright lubricant, and 0.2 parts of octaphenyl cage polysilsesquioxane into a mixer with nitrogen protection and mix at high speed for 10 minutes;

[0049] (3) Under the protection of nitrogen, put the mixed material of (2) into a pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com