Dust control and removal method and system for driving face of driving and anchoring all-in-one machine

A technology of excavation working face and dust removal system, which is applied in the directions of dust prevention, bolt installation, earthwork drilling and mining, etc. It can solve the problem that it is difficult to realize the efficient collection and treatment of flour dust in excavation work, and it is impossible to realize the erection of hard air ducts and the treatment effect Poor and other problems, to achieve the effect of solving serious dust hazards, high promotion value, efficient collection and treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

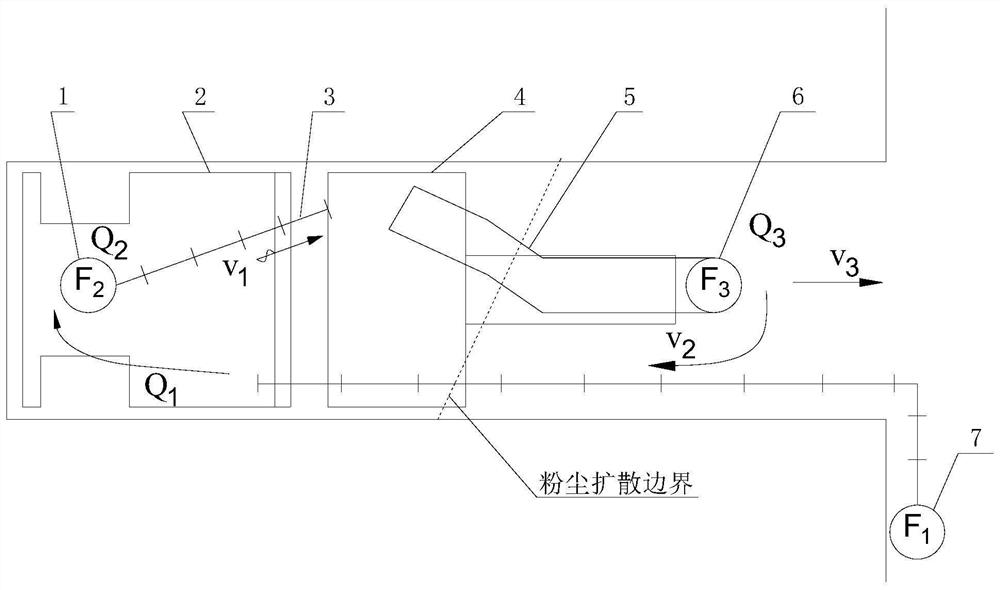

[0031] A control and dust removal system for the excavation working face of an all-in-one machine for digging and bolting, such as figure 1 As shown, F1 is the local air supply fan 7, Q1 is the air supply volume of the excavation surface; F2 is the dust extraction fan 1 designed and fixed on the bolt-digging integrated machine 2, and the air suction volume is Q2; F3 is the dust removal fan 6, and the processing air volume is Q3; The air volume is: Q3>Q1>Q2. Since Q3 is the largest, the head-on air supply volume is smaller than the hard air duct suction volume, a part of the air volume from the air outlet of the dust removal fan 6 enters the exhaust system at a speed of v3, and the other part of the air volume flows to the front at a speed of v2, and the direction is from the roadway to the front. At this time, the stroke from the F3 position to the dust extraction port of the hard negative pressure dust extraction duct 5 is a negative pressure area, which creates the effect of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com