Cyclone dust collector

A cyclone dust collector, cyclone technology, applied in the direction of the swirl device, the device whose axis of the swirl can be reversed, etc., can solve the problems of incomplete dust removal of the wind dust collector, small processing air volume, high dust content in the air outlet, etc., to achieve The effect of thorough dust removal, large air volume and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

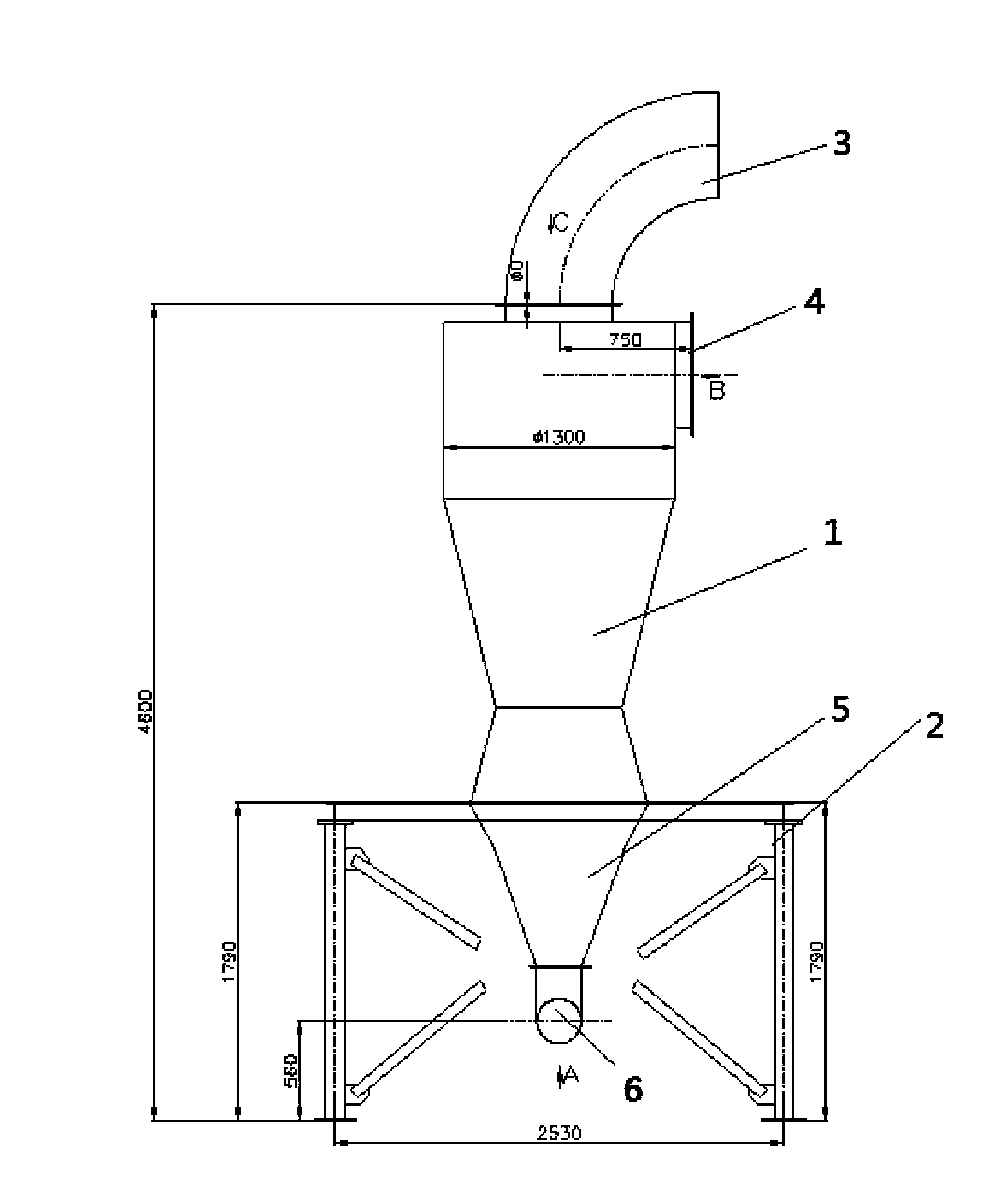

[0018] Such as figure 1 The cyclone dust collector shown includes a cyclone dust collector body 1 and a support frame 2 for supporting the cyclone dust collector body 1; A dust collecting hopper 5 with an inverted "eight" shape is provided in the longitudinal section; a cyclone device is provided at the air inlet 4 of the cyclone dust collector body 1; 1 / 2-1 / 3, the shape of the longitudinal section of the cyclone dust collector body 1 below the air inlet 4 is transformed from an inverted "eight" shape to an "eight" shape, and then combined with the ash collecting bucket 5 whose longitudinal section is an inverted "eight" shape connected. The bottom of the air outlet elbow 3 is provided with a filter screen. The bottom of the ash collecting hopper 5 is provided with the pipeline 6 connecting the blower fan, and the diameter of the ball in the spherical butterfly valve is 295mm. The outer diameter of the top of the cyclone dust collector body is 1290mm. The cross section of ...

Embodiment 2

[0020] Such as figure 1 The cyclone dust collector shown includes a cyclone dust collector body 1 and a support frame 2 for supporting the cyclone dust collector body 1; A dust collecting hopper 5 with an inverted "eight" shape is provided in the longitudinal section; a cyclone device is provided at the air inlet 4 of the cyclone dust collector body 1; 1 / 2-1 / 3, the shape of the longitudinal section of the cyclone dust collector body 1 below the air inlet 4 is transformed from an inverted "eight" shape to an "eight" shape, and then combined with the ash collecting bucket 5 whose longitudinal section is an inverted "eight" shape connected. The bottom of the air outlet elbow 3 is provided with a filter screen. The bottom of the ash collecting hopper 5 is provided with the pipeline 6 connecting the fan, and the diameter of the ball in the spherical butterfly valve is 300mm. The outer diameter of the top of the cyclone dust collector body is 1310mm. The cross section of the air...

Embodiment 3

[0022] Such as figure 1 The cyclone dust collector shown includes a cyclone dust collector body 1 and a support frame 2 for supporting the cyclone dust collector body 1; A dust collecting hopper 5 with an inverted "eight" shape is provided in the longitudinal section; a cyclone device is provided at the air inlet 4 of the cyclone dust collector body 1; 1 / 2-1 / 3, the shape of the longitudinal section of the cyclone dust collector body 1 below the air inlet 4 is transformed from an inverted "eight" shape to an "eight" shape, and then combined with the ash collecting bucket 5 whose longitudinal section is an inverted "eight" shape connected. The bottom of the air outlet elbow 3 is provided with a filter screen. The bottom of the ash collecting hopper 5 is provided with the pipeline 6 connecting the fan, and the diameter of the ball in the spherical butterfly valve is 300mm. The outer diameter of the top of the cyclone dust collector body is 1300mm. The cross section of the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com