Novel high-efficiency dust processor

A processor and high-efficiency technology, applied in chemical instruments and methods, dispersed particle separation, dispersed particle filtration, etc., can solve the problem of inability to clean the dust in the filter cartridge, and achieve the effects of simple structure, extended working life, and safe and reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

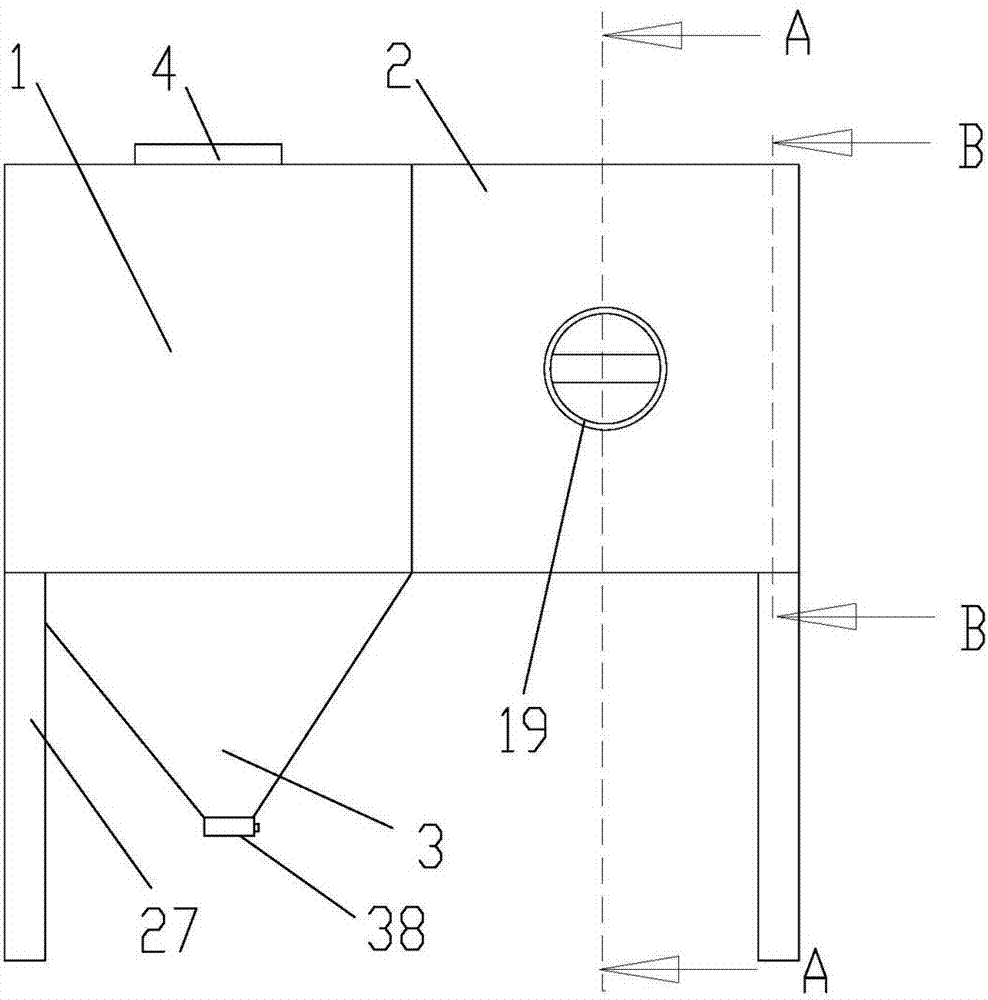

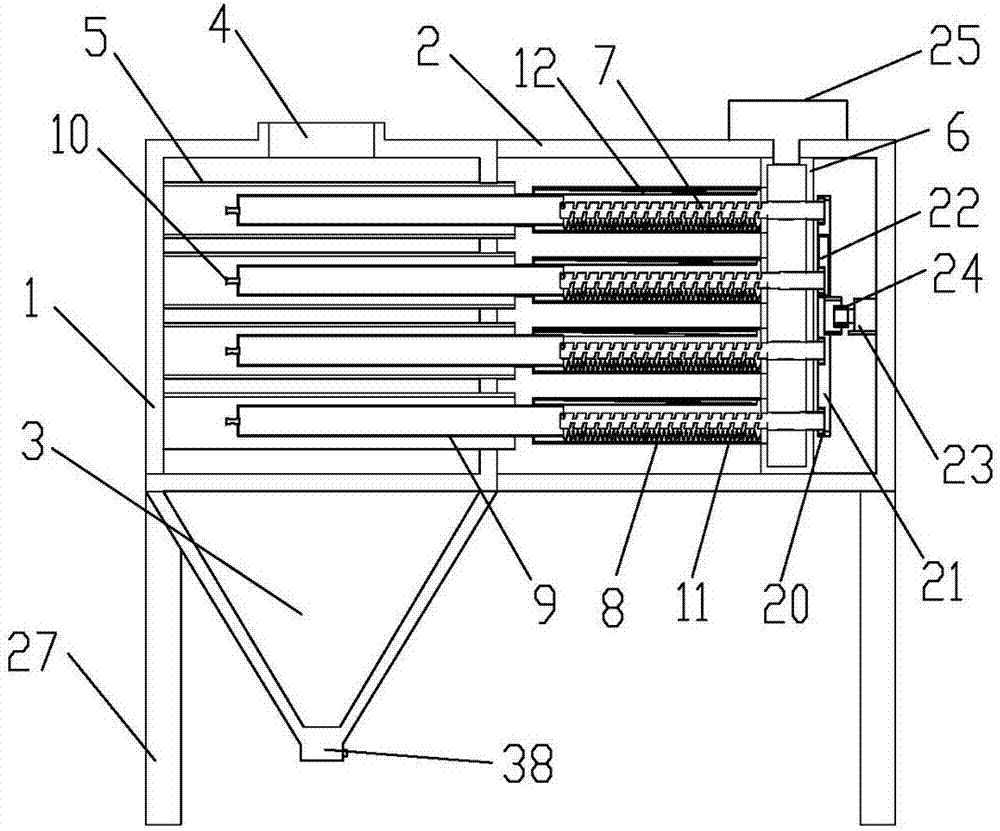

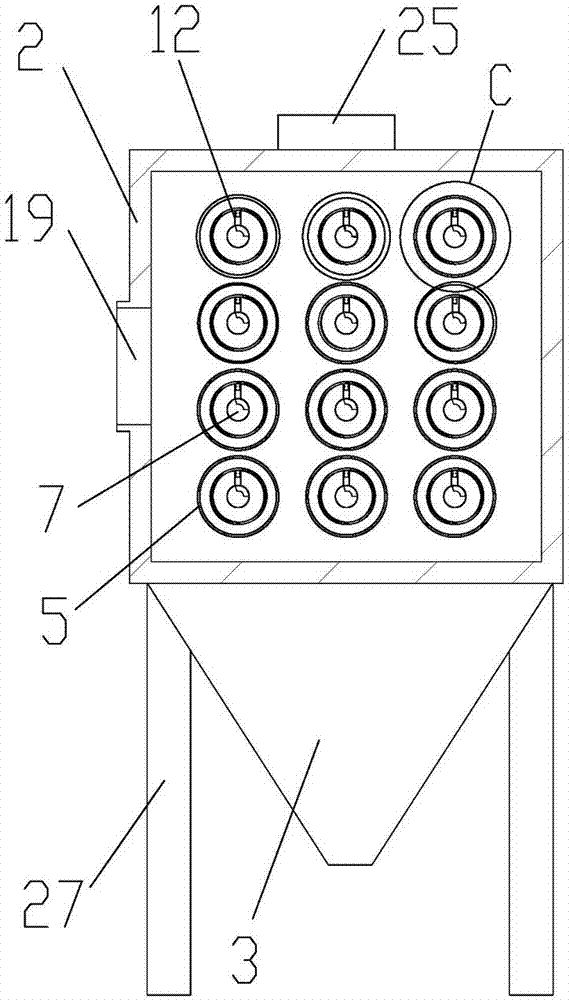

[0019] Depend on Figure 1 to Figure 9 Given, the present invention comprises dust removal box 1, and dust removal box 1 upper surface is provided with air inlet 4, and dust removal box 1 right end is fixedly installed with work box 2, and the front side of work box 2 is provided with air outlet 19, and dust removal box 1 is evenly distributed There are multiple horizontal filter cartridges 5, one end of the filter cartridge 5 is fixed on the inner wall on the left side of the dust removal box 1, the other end of the filter cartridge 5 passes through the dust removal box 1 and extends into the working box 2, and the working box 2 is fixedly installed with a The inside of the working box 2 is divided into a left and right ventilation box 6. A plurality of rotating shafts 7 located in the axial center of the filter cartridge 5 are installed in the ventilation box 6. The rotating shafts 7 run through the left side and the right side of the ventilation box 6. 7 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com