Rapid separation device and method for protein and starch in wastewater produced during starch processing

A separation device and starch processing technology, applied in chemical instruments and methods, water pollutants, precipitation treatment, etc., can solve the problems of expensive membrane modules, large floor space, and reduced protein quality, and reduce nutrients and COD values. , the cost of capital construction and operation are low, and the effect of improving separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

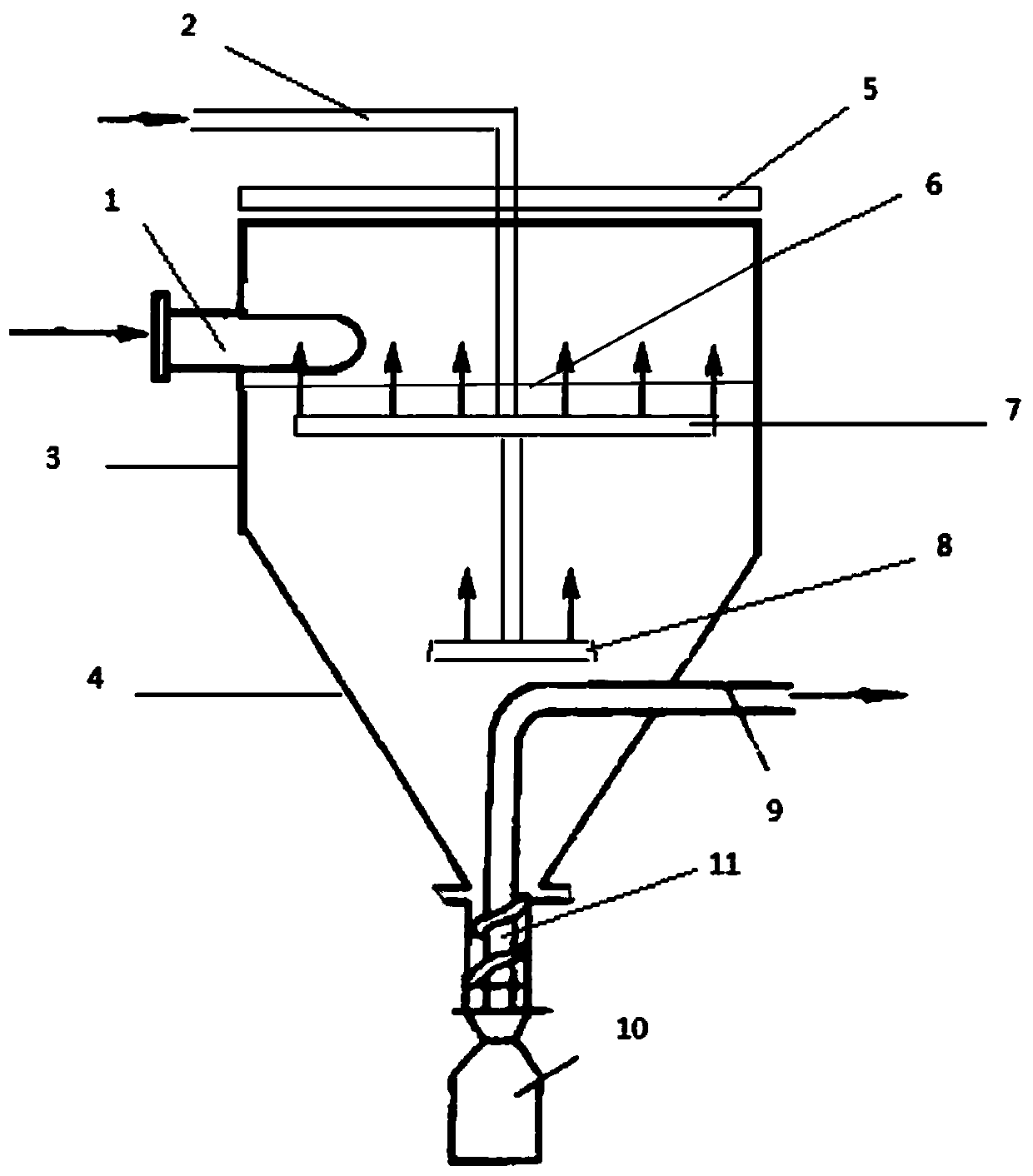

[0055] A rapid separation device for protein and starch in starch processing waste water, comprising a separation device body (stainless steel material), a starch collection device 10, a frothing device, a foam blowing device and a skimming device.

[0056] The separation device body includes a cylindrical section 3 and an inverted cone section 4.

[0057] The cylindrical section 3 has a height of 3m, a diameter of 1.5m, an open top, and a feed inlet 1 is provided on the side wall 0.70m away from the top;

[0058] The angle between the bus bar and the top surface of the inverted cone section 4 is 60 ° , the top of the inverted cone section 4 is integrally formed with the bottom of the cylindrical section 3 , and the bottom of the inverted cone section 4 is connected to the starch collecting device 10 .

[0059] A liquid discharge pipe 9 is arranged in the inverted cone section 4;

[0060] The liquid discharge pipe 9 is "L" shaped, the water inlet is located at the inner bott...

Embodiment 2

[0069] The processing time of sweet potato starch is short, and the daily output is large, and the wastewater generated in the processing of sweet potato starch can be quickly treated by the device of embodiment 1.

[0070] Make sweet potato starch extraction waste water with 10m 3 The speed of / h enters the liquid injector, and the gas is brought in and evenly distributed in the sweet potato starch extraction wastewater to form a relatively stable protein foam.

[0071] Pump the waste liquid containing foam into the main body of the separation device along the tangential direction at a linear velocity of 5m / s. Air is introduced through the vent pipe 2. When the liquid level reaches 0.2m below the feed inlet, open the liquid discharge pipe 9.

[0072] Use the skimming device 5 to skim off the foam, collect and break the emulsion to obtain the protein product.

[0073] The starch settles and falls into the starch collecting device 10 .

[0074] Waste water after having sepa...

Embodiment 3

[0077] Use the apparatus of embodiment 1 to treat the waste water of pea starch processing process.

[0078] 0.05MPa compressed air is introduced into pea starch extraction waste water according to 10% (volume ratio) to form relatively stable protein foam.

[0079] Pump the foamy waste water into the main body of the separation device along the tangential direction at a linear velocity of 8m / s. Air is introduced through the vent pipe 2. When the liquid level reaches 0.4m below the feed inlet, open the liquid discharge pipe 9.

[0080] Use the skimming device 5 to skim off the foam, collect and break the emulsion to obtain the protein product.

[0081] The starch settles and falls into the starch collecting device 10 .

[0082] Waste water after having separated starch and albumen flows out through liquid discharge pipe 9.

[0083] The initial COD of the treated wastewater is about 15000mg / L, and after treatment, the COD drops to about 5500mg / L, and the COD removal rate is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com