Screw assembly for nano-powder master batch processing

A technology of screw combination and nano-powder, which is applied in the field of powder processing equipment, can solve the problems of affecting the performance of raw materials, low quality of raw material mixing and plastic, and unstable meshing and shearing, so as to achieve good quality of plastic and less heat of friction ,Screw meshing and shearing effect is stable and uniform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

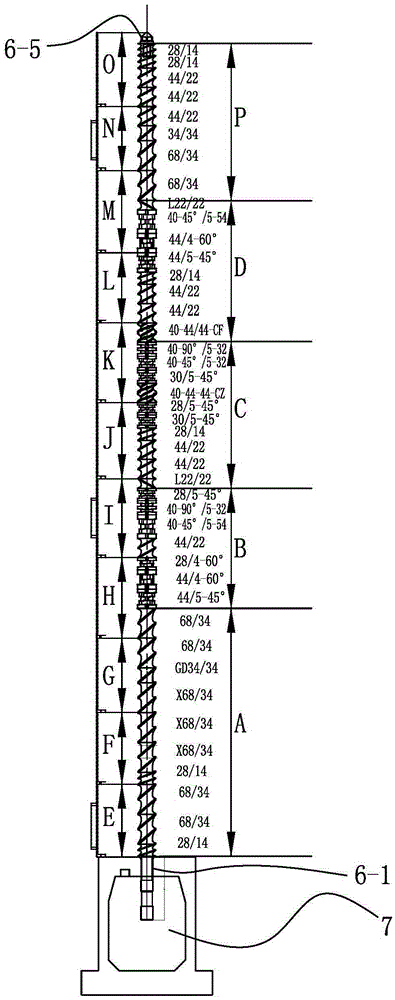

[0030] Example 1: as figure 1 Shown: a screw combination for nano-powder masterbatch processing, including a twin-screw extruder, and a barrel arranged on the twin-screw extruder; two parallel screws 6 are arranged in the barrel, Each screw 6 is installed with a plurality of screw parts of different specifications; the screw 6 is symmetrically arranged in the barrel, and the rotation direction is the same,

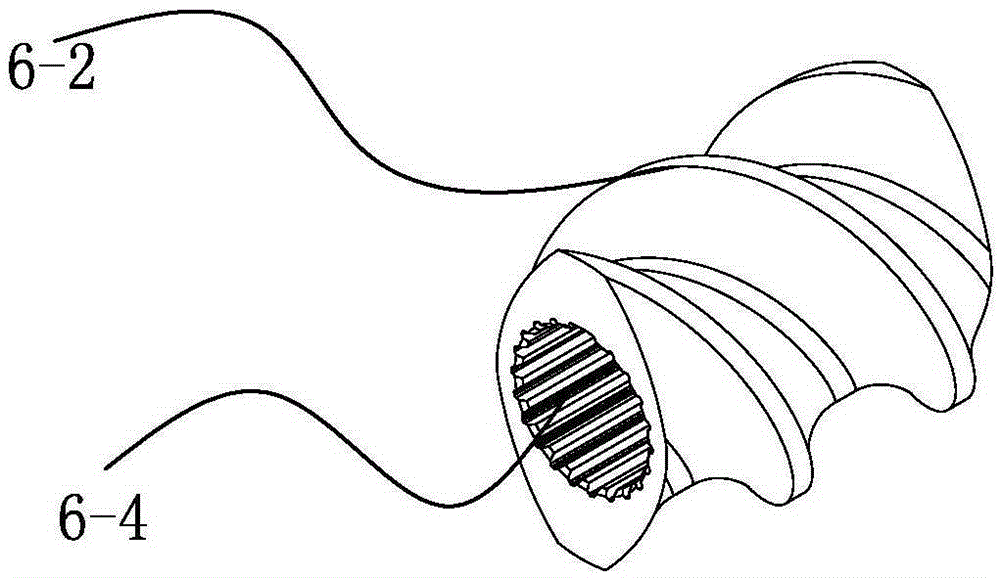

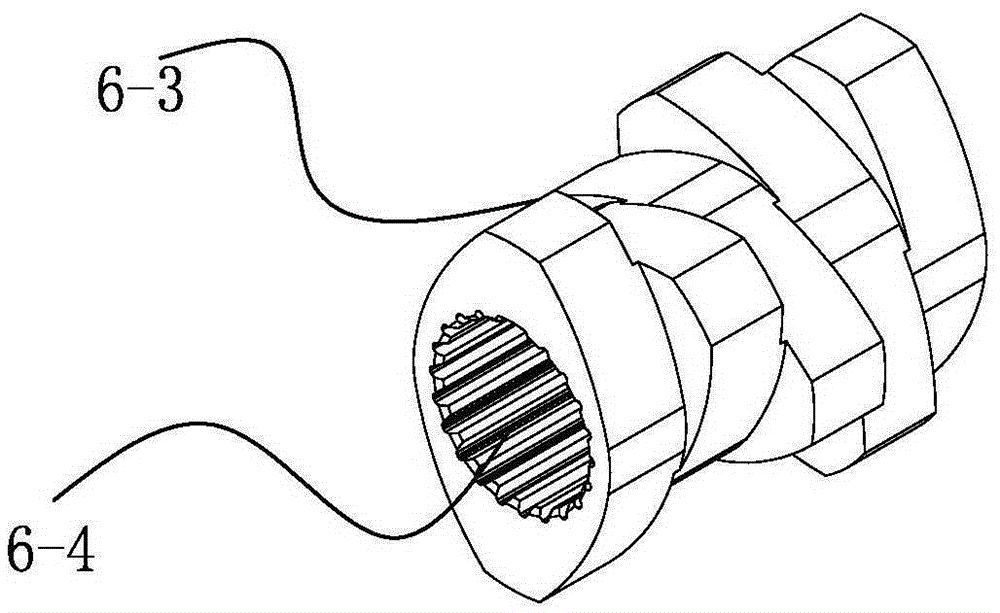

[0031] One end of the screw 6 is connected to a screw bearing 7, and the screw bearing 7 drives the screw 6 to rotate. The screw 6 includes a spline shaft 6-1 with a spline, a screw element 6-2 and a kneading element 6-3; The inner holes of the threaded element 6-2 and the kneading element 6-3 are provided with spline grooves 6-4 corresponding to the splines on the splined shaft 6-1; a plurality of different forward and reverse threaded elements 6-2 and A plurality of different positive and reverse kneading elements 6-3 are arranged on the spline shaft 6-1 in sequence, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com