Patents

Literature

38results about How to "Remove applicable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

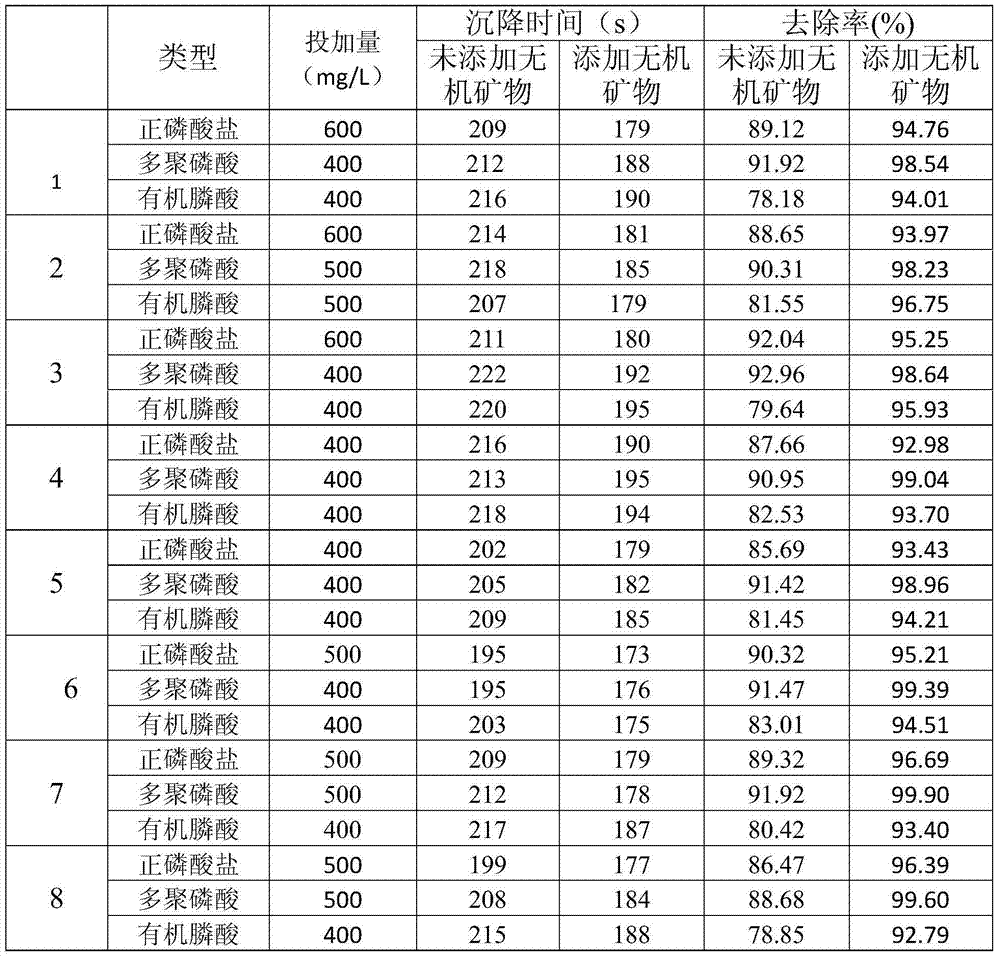

Phosphorus removing agent containing inorganic mineral and application method thereof

ActiveCN104291420AAccelerated settlementSpeed up the flocculation processWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionChemistryPhosphate

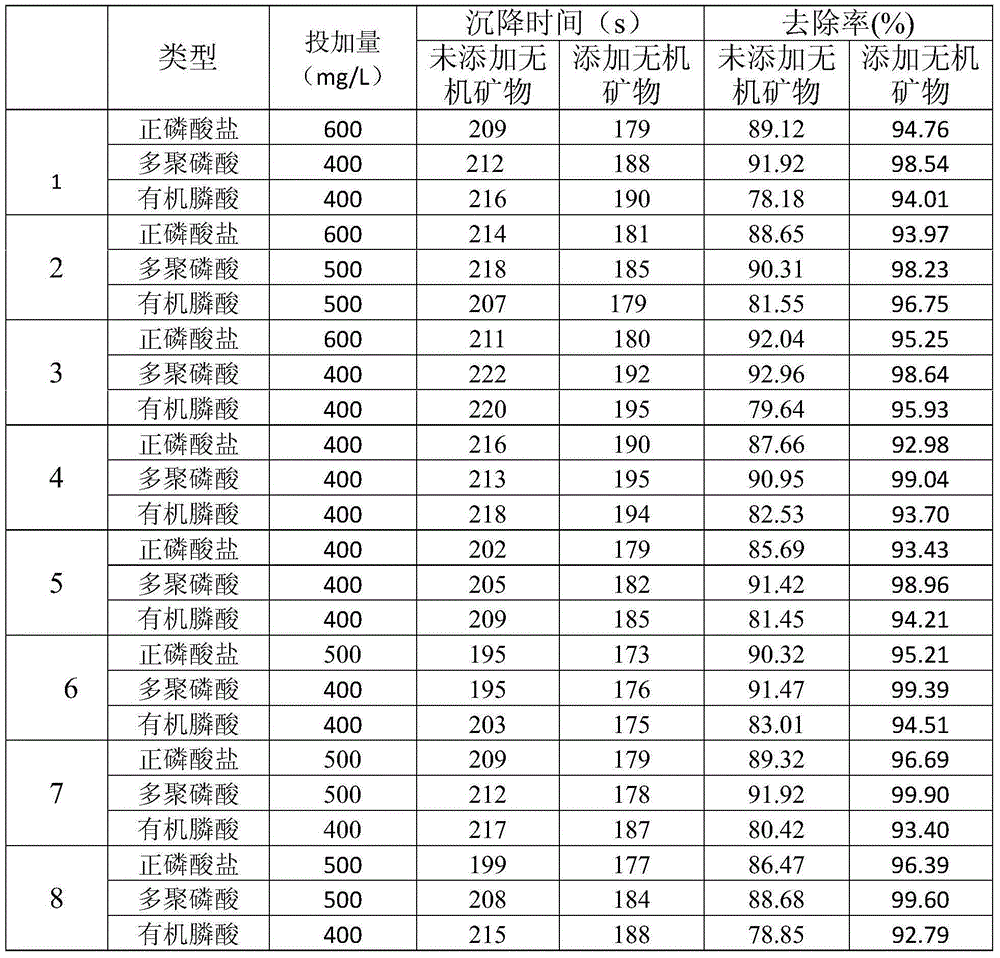

The invention relates to a phosphorus removing agent containing inorganic mineral and an application method thereof. The phosphorus removing agent contains 50-75% of an aluminium-containing compound, 15-30% of an inorganic mineral adsorbent and 10-20% of an iron-containing compound, and also can be compounded with a B component. By the use of the phosphorus removing agent, inorganic phosphorus and organic phosphorus in wastewater are removed effectively. By the addition of the inorganic mineral adsorbent, phosphates are fully adsorbed, and the inorganic mineral adsorbent can be combined with iron hydroxide and dried aluminium hydroxide gel generated during the reaction. Thus, more phosphates and pollutants in water can be adsorbed to form larger floc, and settling and flocculation processes are accelerated. Through the synergistic effect of substances, a better phosphorus removing effect is achieved. The phosphorus removing agent has a very good effect of processing orthophosphate, polyphosphates and organic phosphorus and especially has a function of efficiently removing organic phosphorus. In addition, the application method of the phosphorus removing agent is simple.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

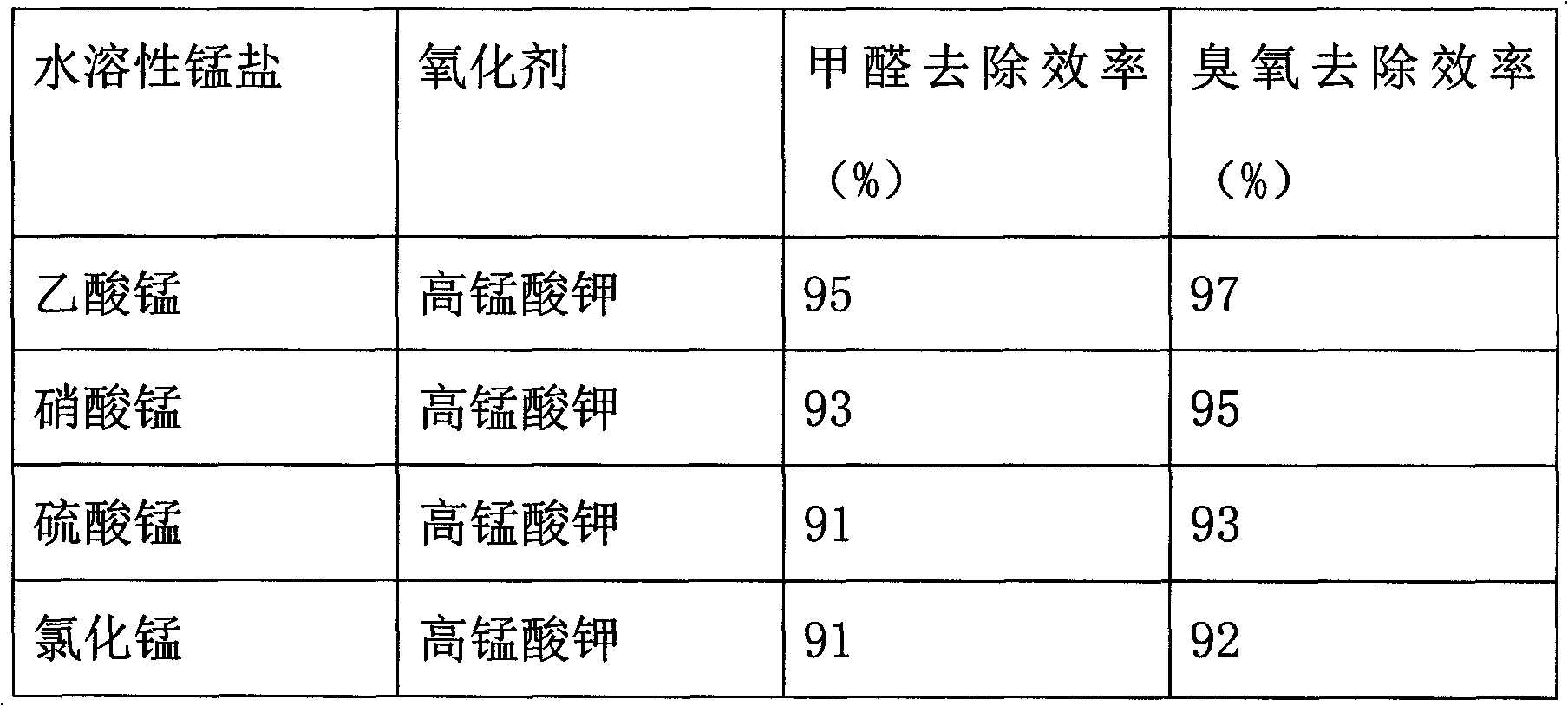

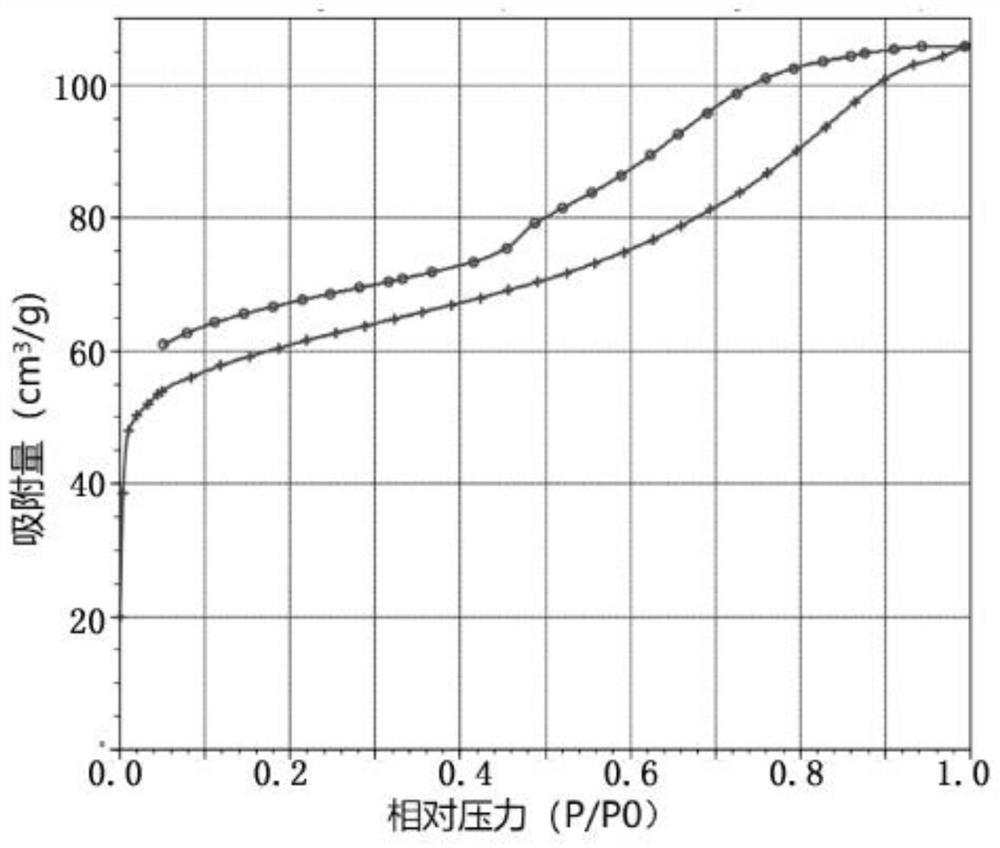

Method for preparing formaldehyde and ozone removal catalyst at room temperature

InactiveCN103506111AImprove removal efficiencyEfficient removalDispersed particle separationManganese oxides/hydroxidesFiltrationManganese

The invention relates to a method for preparing a formaldehyde and ozone removal catalyst MnO2 at room temperature. The method is characterized by comprising the following steps: 1, preparing a 0.1 to 2mol / L solution from a water-soluble manganese salt; 2, preparing a 0.05 to 1mol / L solution from an oxidizing agent; 3, continuously dropwise adding the solution obtained by the step 2 into the solution obtained by the step 1 at a constant speed; 4, aging produced MnO2 suspension for 1 to 1 hour; 5, washing precipitates obtained by aging for 1 to 5 times by using water, drying the precipitates at 105 DEG C after suction filtration, and roasting the precipitates at 200 to 300 DEG C to obtain the catalyst MnO2. The catalyst MnO2 prepared by the method can be used for simultaneously decomposing harmful gases formaldehyde and ozone in contaminated air into harmless H2O and CO2 under a room temperature condition, and has the advantages of no harmful byproducts and high formaldehyde and ozone removal efficiency.

Owner:罗平

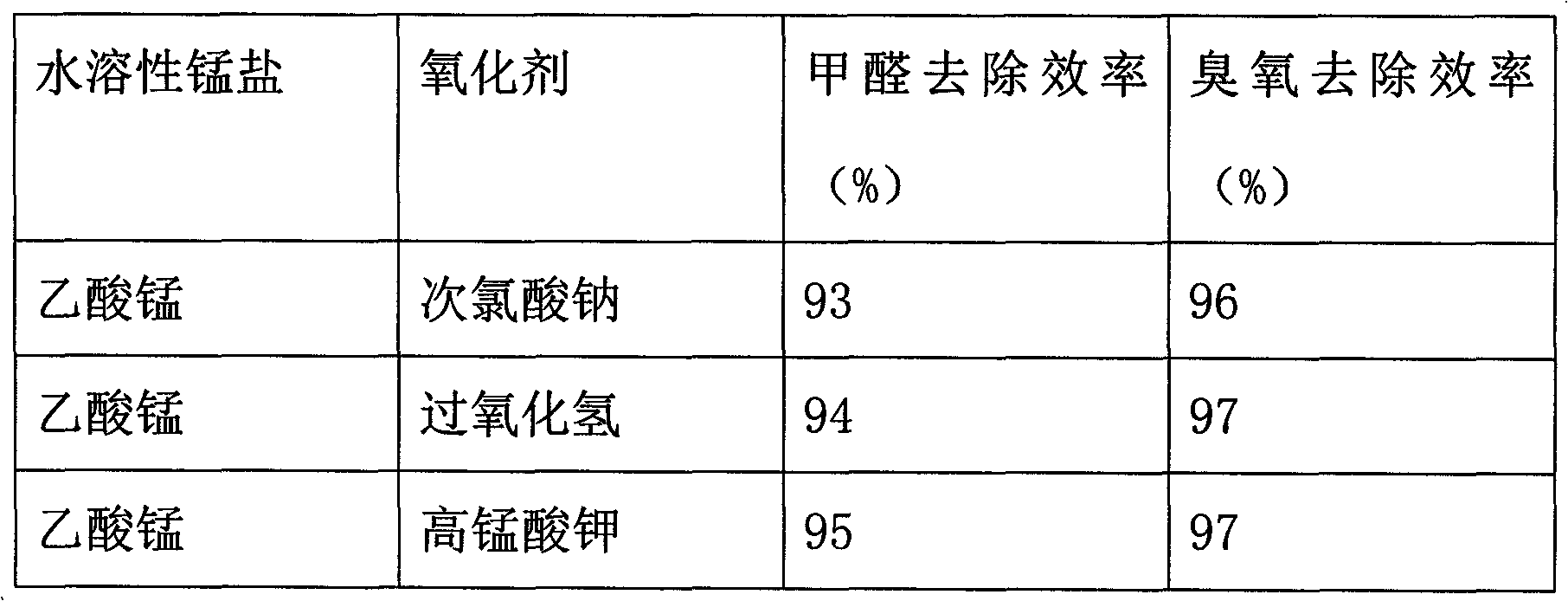

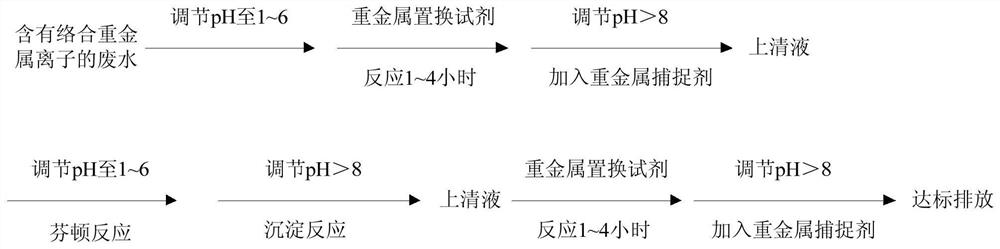

Method for removing complexed heavy metal ions in water body

ActiveCN107364985AEfficient removalEffective network breakWater treatment compoundsWater contaminantsTreated waterReagent

The invention specifically relates to a method for removing complexed heavy metal ions in a water body, belonging to the technical field of wastewater treatment. The method provided by the invention comprises the following steps: reacting a water body containing complexed heavy metal ions with a heavy metal replacement reagent, and then adding a heavy metal capturing agent. The method for removing complexed heavy metal ions in the water body is simple and easy to operate, low in cost and capable of efficiently removing heavy metal ions in a wide concentration range, and the concentration content of heavy metal ions in treated water is less than 0.1 ppm.

Owner:CHONGQING MOLECULAR WATER SYST

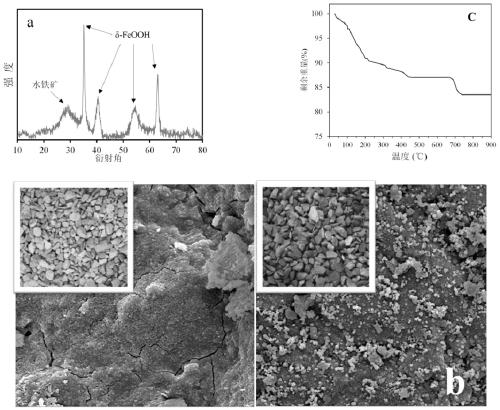

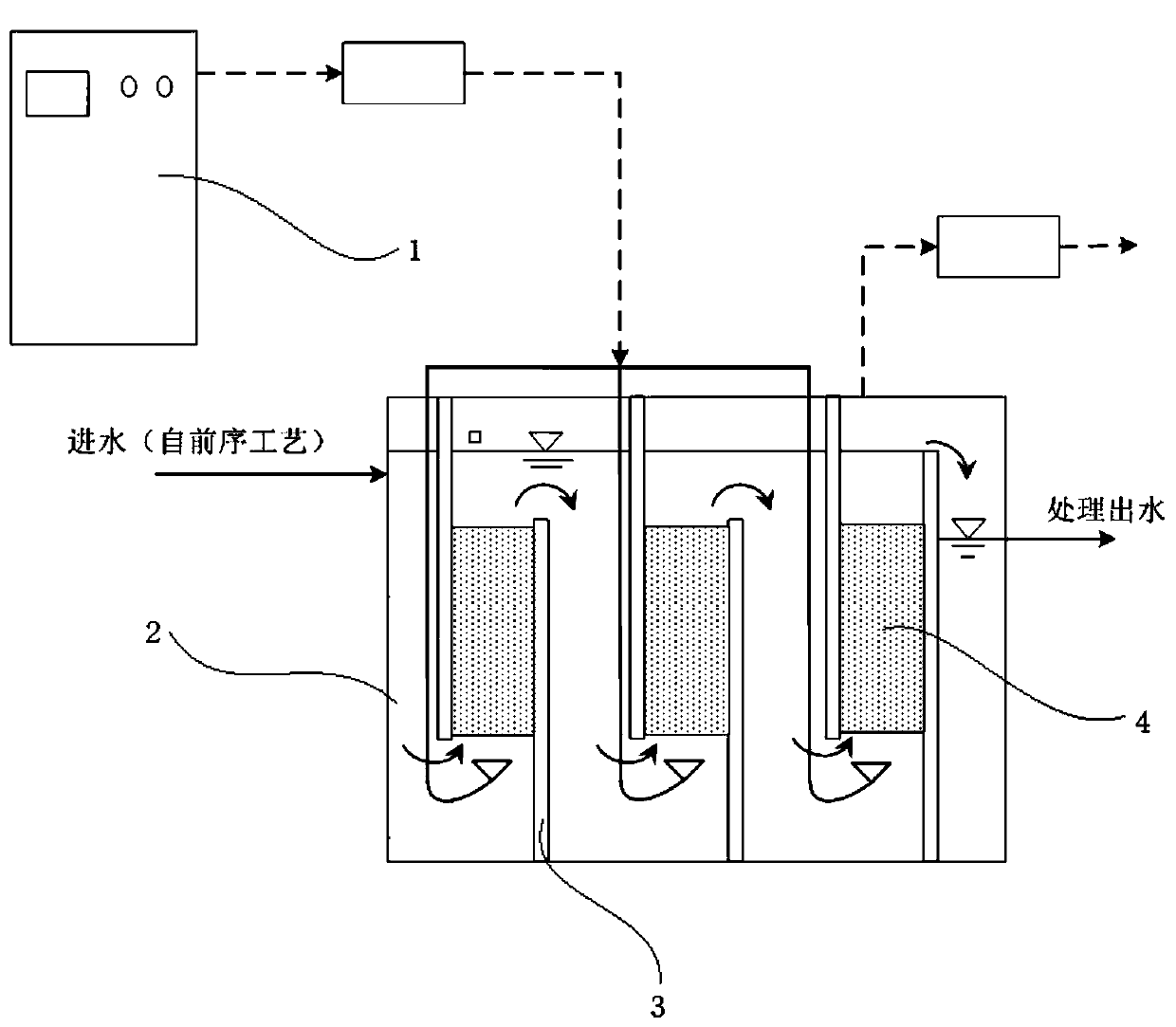

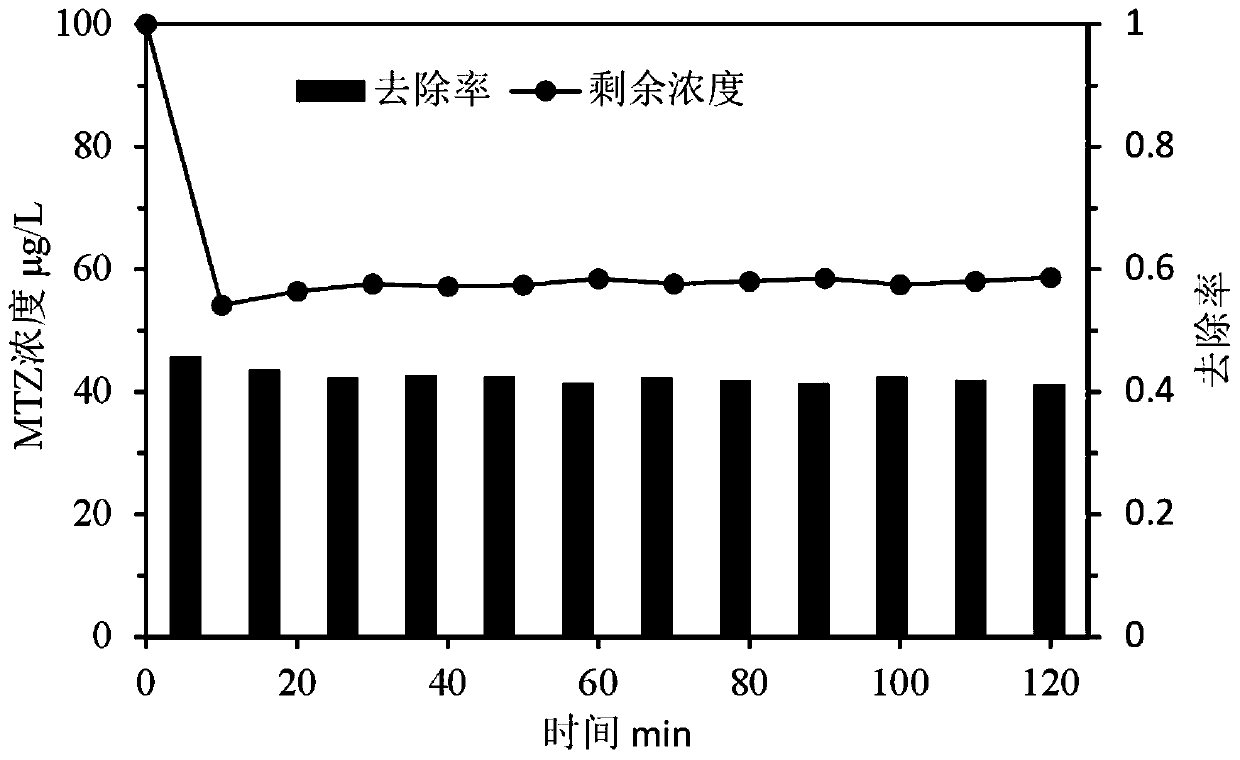

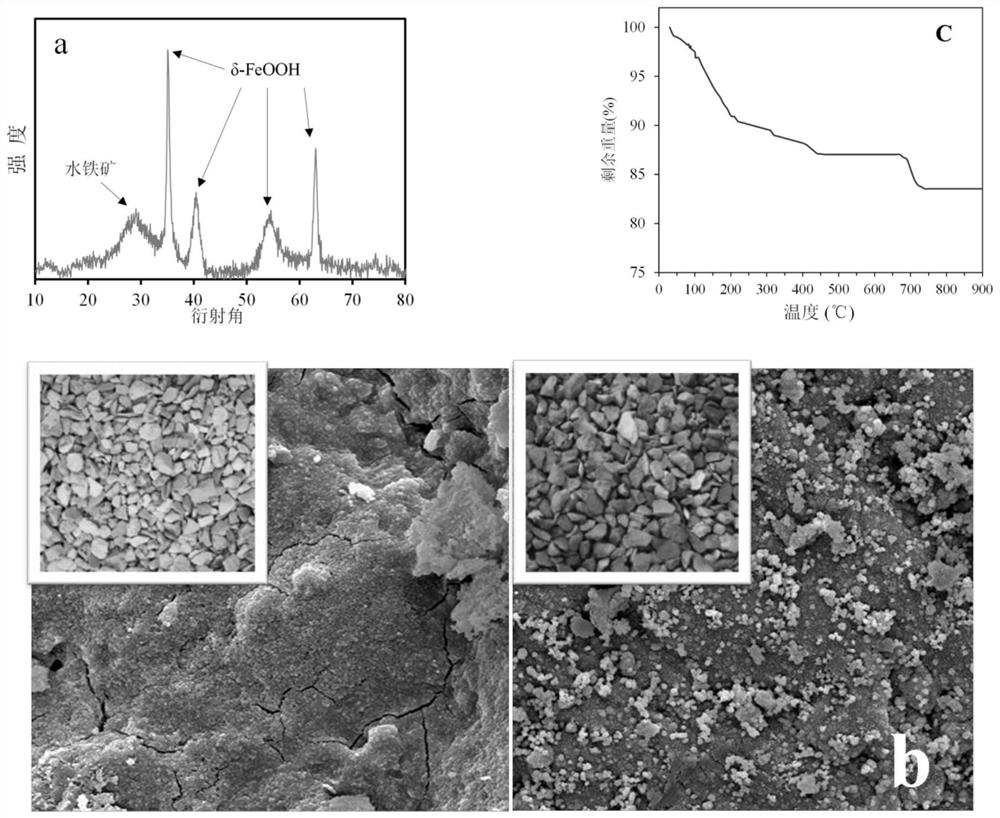

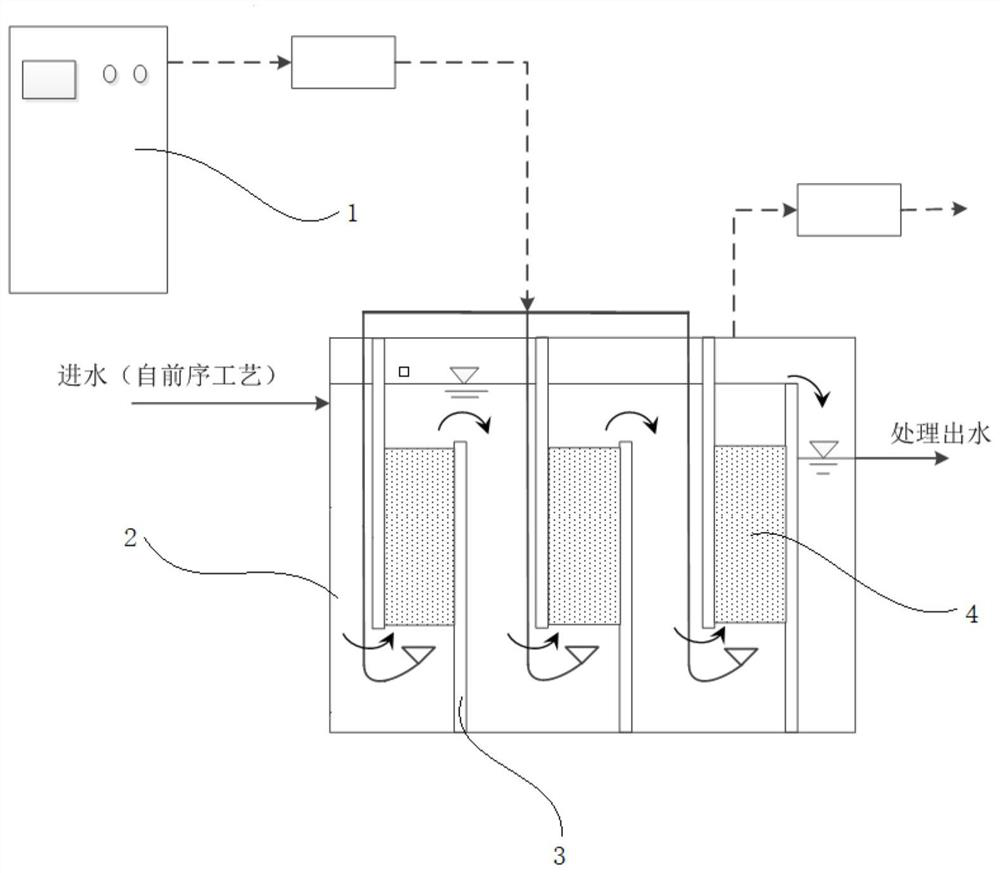

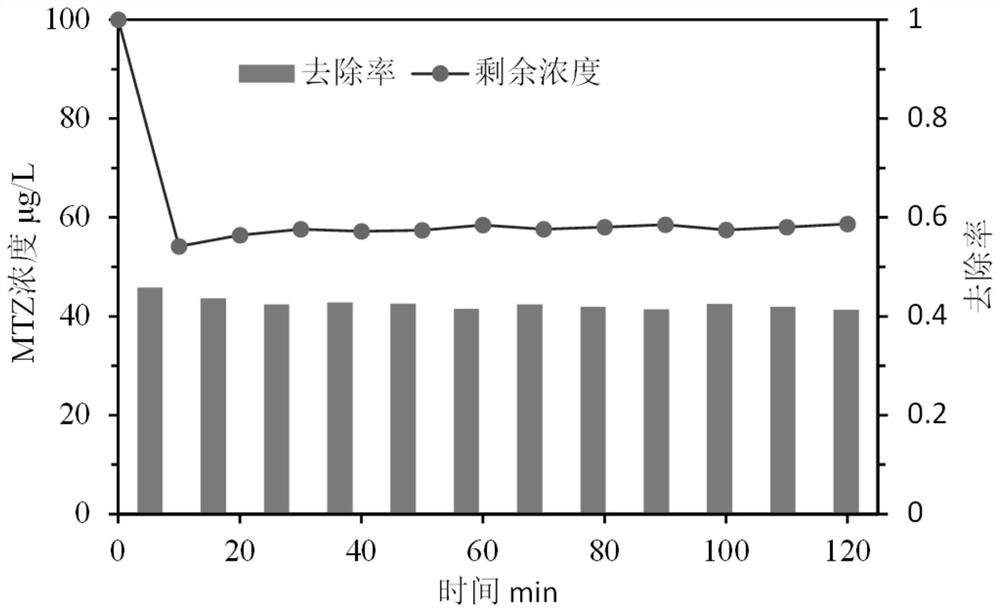

Iron-based catalyst for strengthening ozone oxidation of organic pollutants and preparation method thereof

ActiveCN110075845AGuaranteed disinfection effectIncrease profitWater treatment compoundsSpecific water treatment objectivesActive componentAntibiotic Y

The invention provides an iron-based catalyst for strengthening ozone oxidation of organic pollutants. The catalyst can efficiently catalyze the organic pollutants which are difficult to degrade by the ozone oxidation under the condition of low ozone concentration to remove difficultly degraded organic substances, and is prepared by taking natural zeolite, artificial zeolite or a zeolite-like material as a carrier loaded with active components, wherein the active components comprise ferrihydrite and delta-hydroxyl oxidize iron in a mass ratio of (20 to 80): (20 to 80); the invention further provides a preparation method of the catalyst and a method for treating wastewater by using the catalyst which can effectively remove antibiotics such as metronidazole difficult to degrade in hospital wastewater; furthermore, the invention improves a disinfection device of existing hospital wastewater, namely a filling layer of the iron-based catalyst is added in an ozone contact pool, thereby not only disinfecting wastewater, but also decomposing the antibiotics in wastewater without changing original operating parameters.

Owner:CHONGQING UNIV

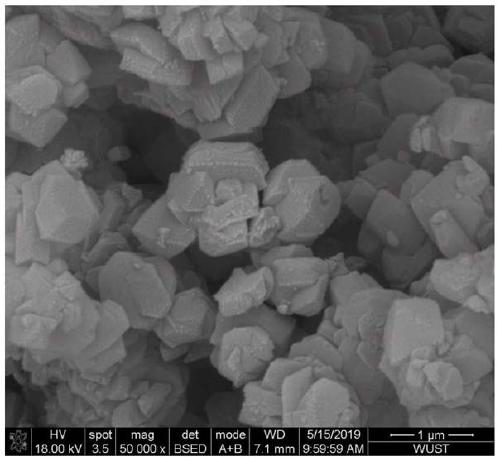

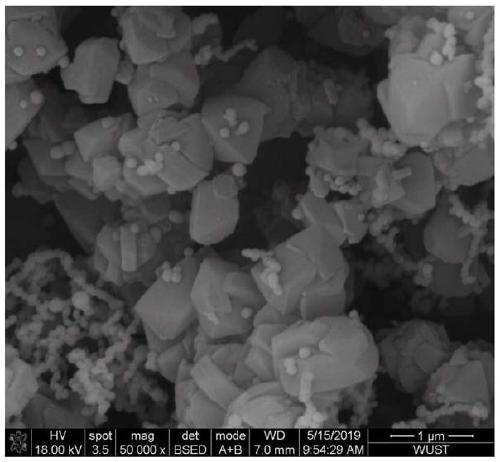

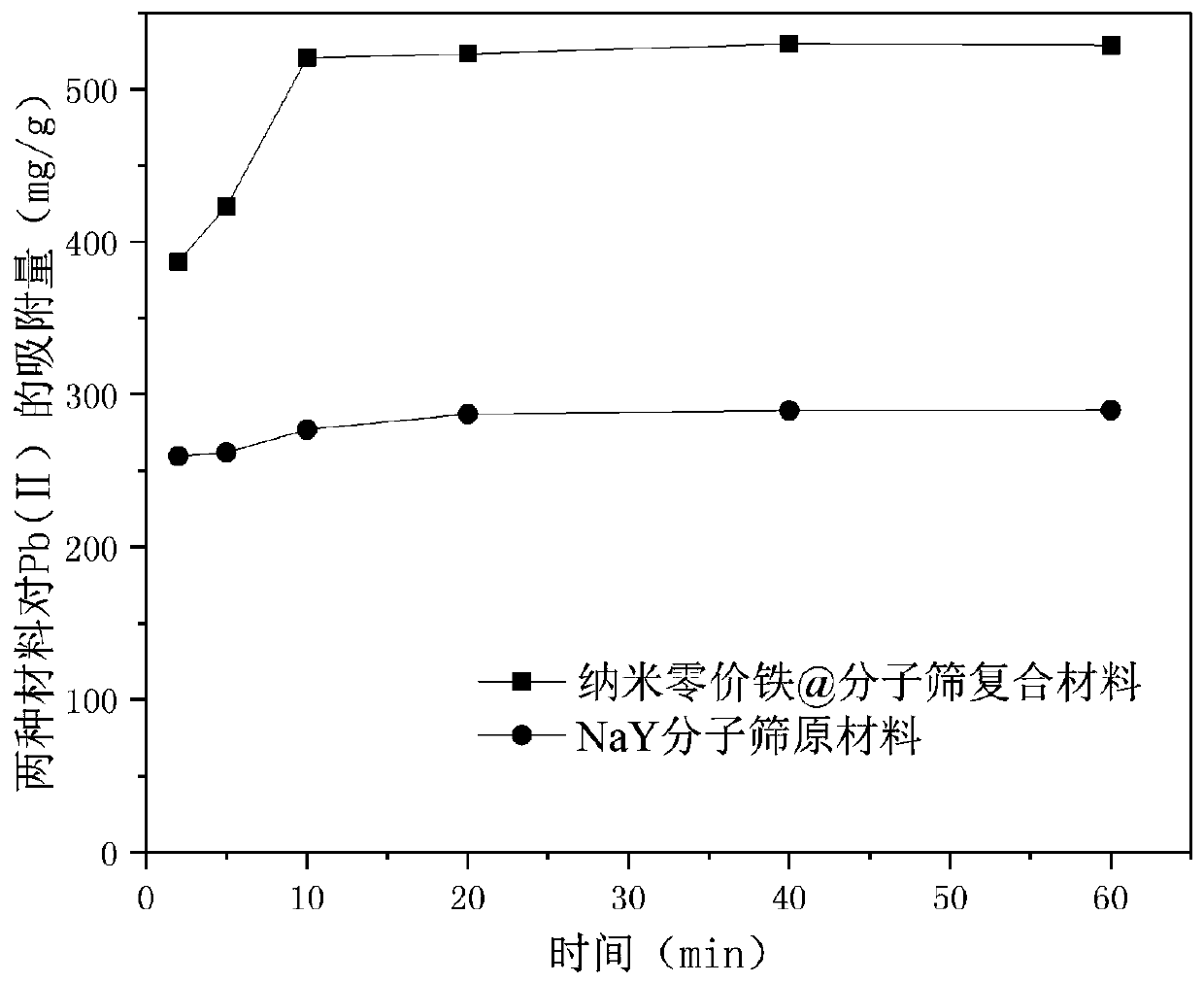

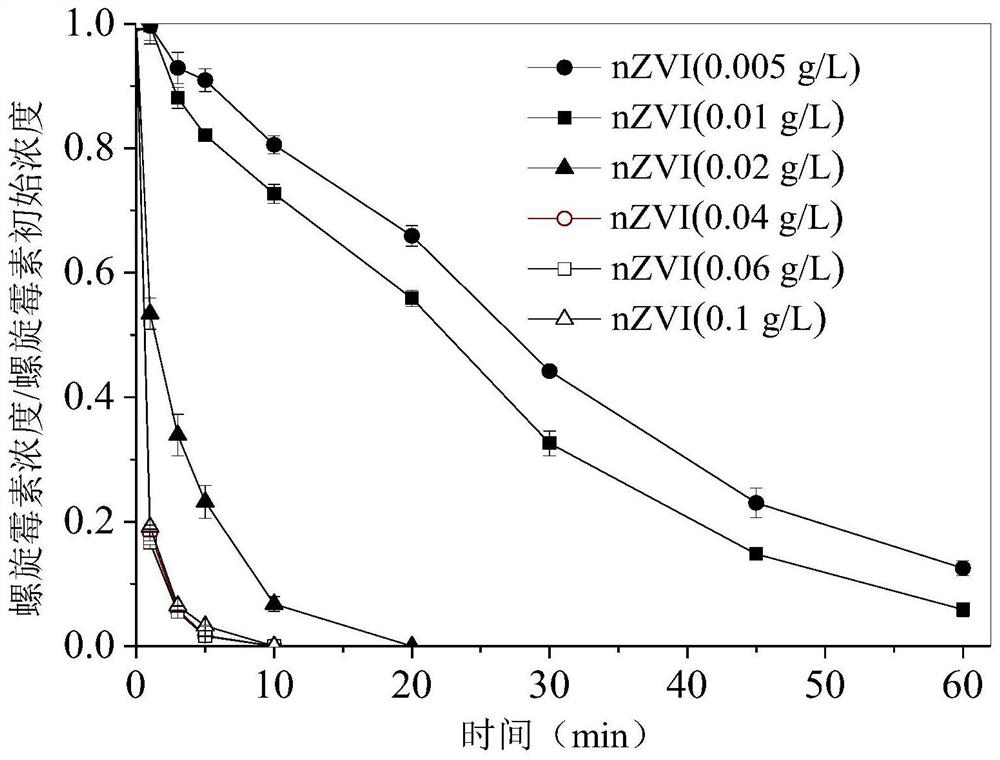

Nano zero valent iron @ molecular sieve composite material and preparation method and applications thereof

InactiveCN110451597AReduce reunionPrevent surface oxidationWater contaminantsWater/sewage treatment by sorptionIron saltsNitrogen gas

The invention relates to a nano zero valent iron @ molecular sieve composite material and a preparation method and applications thereof. The preparation method comprises following steps: preparing aniron salt solution; adding molecular sieves into the iron salt solution; mechanically stirring the iron salt solution under the protection of nitrogen so as to introduce iron ions into the molecular sieves to obtain a mixed solution (A) containing molecular sieves and iron salts; subjecting the mixed solution (A) to solid-liquid separation; after separation, mixing the solids with water to obtaina mixed reaction solution; under the protection of nitrogen and mechanical stirring, adding a solution of a reducing agent into the mixed reaction solution, keeping on stirring to obtain a mixed solution (B); subjecting the mixed solution (B) to solid-liquid separation; and finally washing and drying the obtained solids after separation to obtain the nano zero valent iron @ molecular sieve composite material. The synthesized nano zero valent iron @ molecular sieve composite material has a cation exchange function of molecular sieves and an adsorption-reduction function of nano zero valent ironand has a good effect on removing cations of heavy metals such as Pb<2+>, Cu<2+>, etc. and anions such as ions of arsenous acid.

Owner:WUHAN UNIV OF SCI & TECH

Method for rapidly removing thermal spraying coating

ActiveCN104858792AIncrease air source pressureShort removal timeAbrasion apparatusAbnormal shapedCermet

The invention discloses a method for rapidly removing a thermal spraying coating. A sand blasting material adopts alloy sand with diameters being 0.5-5.0 mm, special-shaped alloy sand with the ratio of length to width being 1.0-5.0 as well as 10-50-mesh ceramic sand, wherein the mass ratio of the alloy sand to the special-shaped alloy sand to the ceramic sand is (1-4):(1-4):1; before sand blasting, three raw materials are uniformly poured into an iron barrel simultaneously, mixing of the raw materials is facilitated, the mixed sand in the iron barrel is poured into a sand tank for sand blasting, and the air source pressure for sand blasting is 0.5-0.9 MPa. The sand composition is optimized and improved, the air source pressure is increased, the removal time of an old coating is greatly shortened, and compared with the time for old coating removal through single ceramic sand blasting, the time is shortened by 60%-75%; meanwhile, the production cost is reduced, the old coating is economically and efficiently removed, and the method is suitable for removing various metal coatings, alloy coatings and metal ceramic coatings.

Owner:XIAN THERMAL POWER RES INST CO LTD

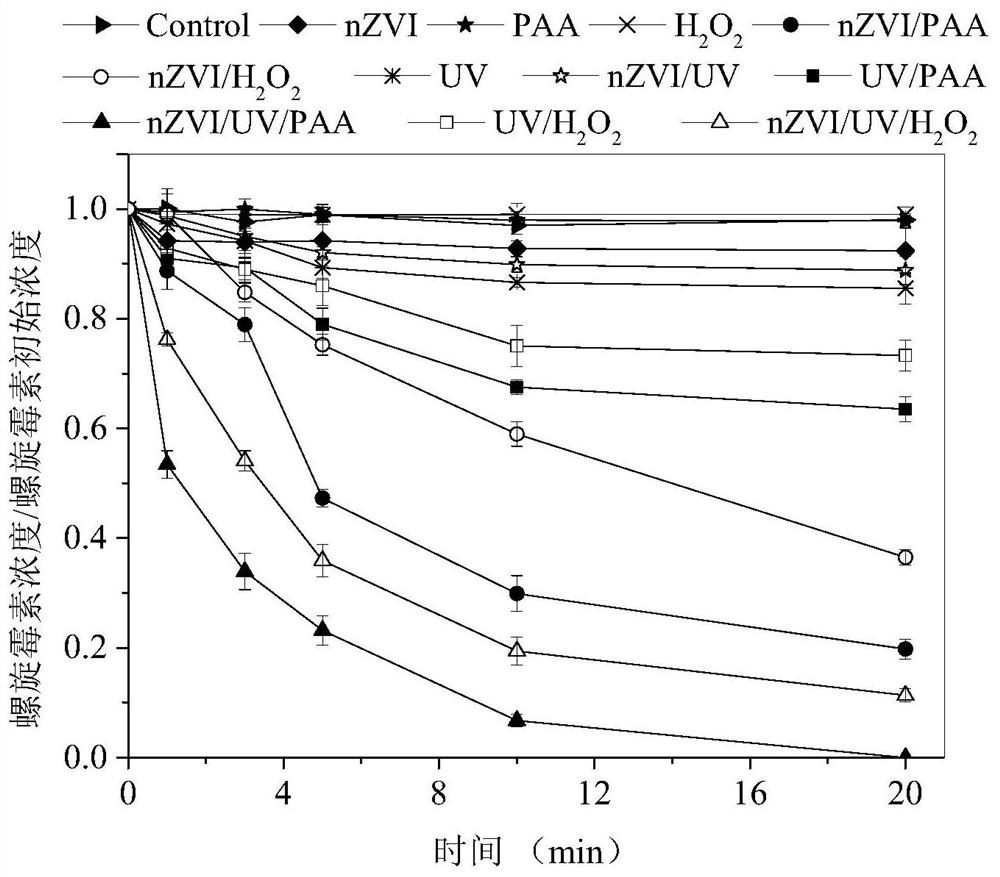

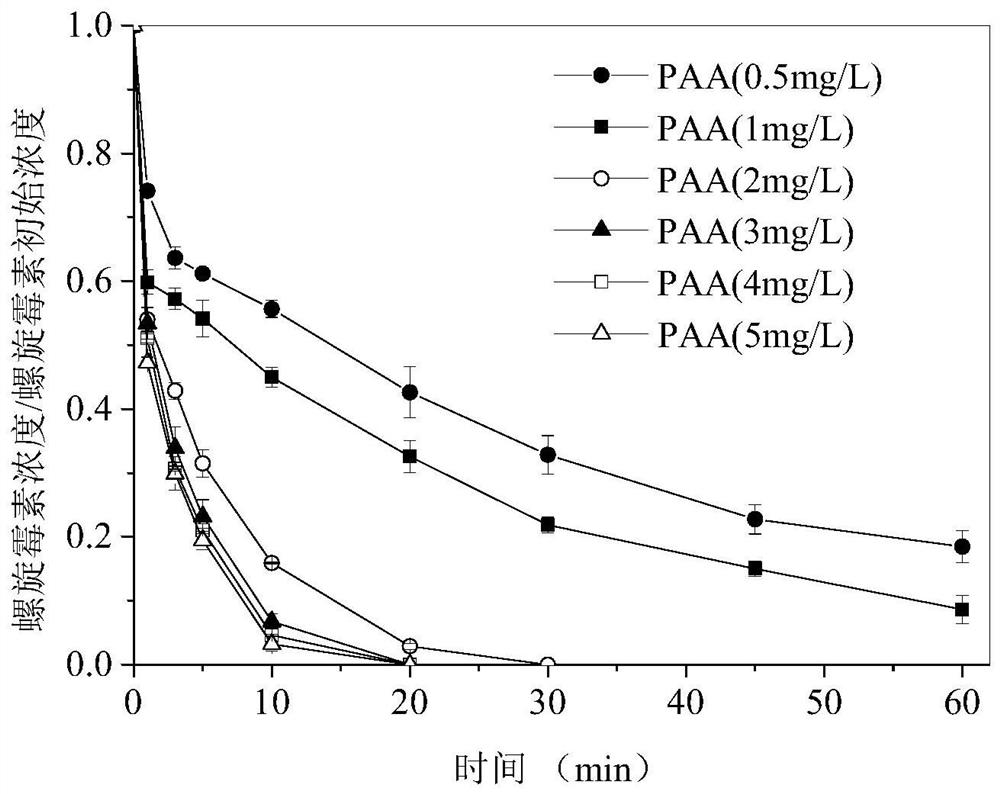

Method for synergistically degrading refractory organic matters in village and town sewage by using hydrogen peroxide component in low-concentration peracetic acid

PendingCN113415869AHigh reusabilityRemove applicableWater/sewage treatment by irradiationWater treatment compoundsPtru catalystPhoto irradiation

The invention provides a method for synergistically degrading refractory organic matters in village and town sewage by using a hydrogen peroxide component in low-concentration peracetic acid. The method comprises the following steps of: adding nano zero-valent iron serving as a catalyst and a low-concentration peracetic acid solution which serves as an oxidant and contains hydrogen peroxide into water containing antibiotics; irradiating the mixed solution by using ultraviolet light emitted by a low-pressure mercury lamp 1; using the nano zero-valent iron and the ultraviolet light to jointly activate strong oxidizing free radicals generated by the oxidant, and using the direct photolysis effect of the ultraviolet light to synergistically degrade the refractory organic matters in the village and town sewage. According to the method, the hydrogen peroxide in low-concentration peracetic acid is used for cooperating with peracetic acid, the nZVI catalyst is added, meanwhile, ultraviolet irradiation is carried out to construct an nZVI / UV / PAA heterogeneous strengthening system, and nZVI and UV are used for activating to generate strong oxidizing free radicals to oxidize and remove antibiotics; the method has the advantages of high treatment efficiency, simplicity and convenience in operation, good reusability of the catalyst, low cost and the like.

Owner:TONGJI UNIV

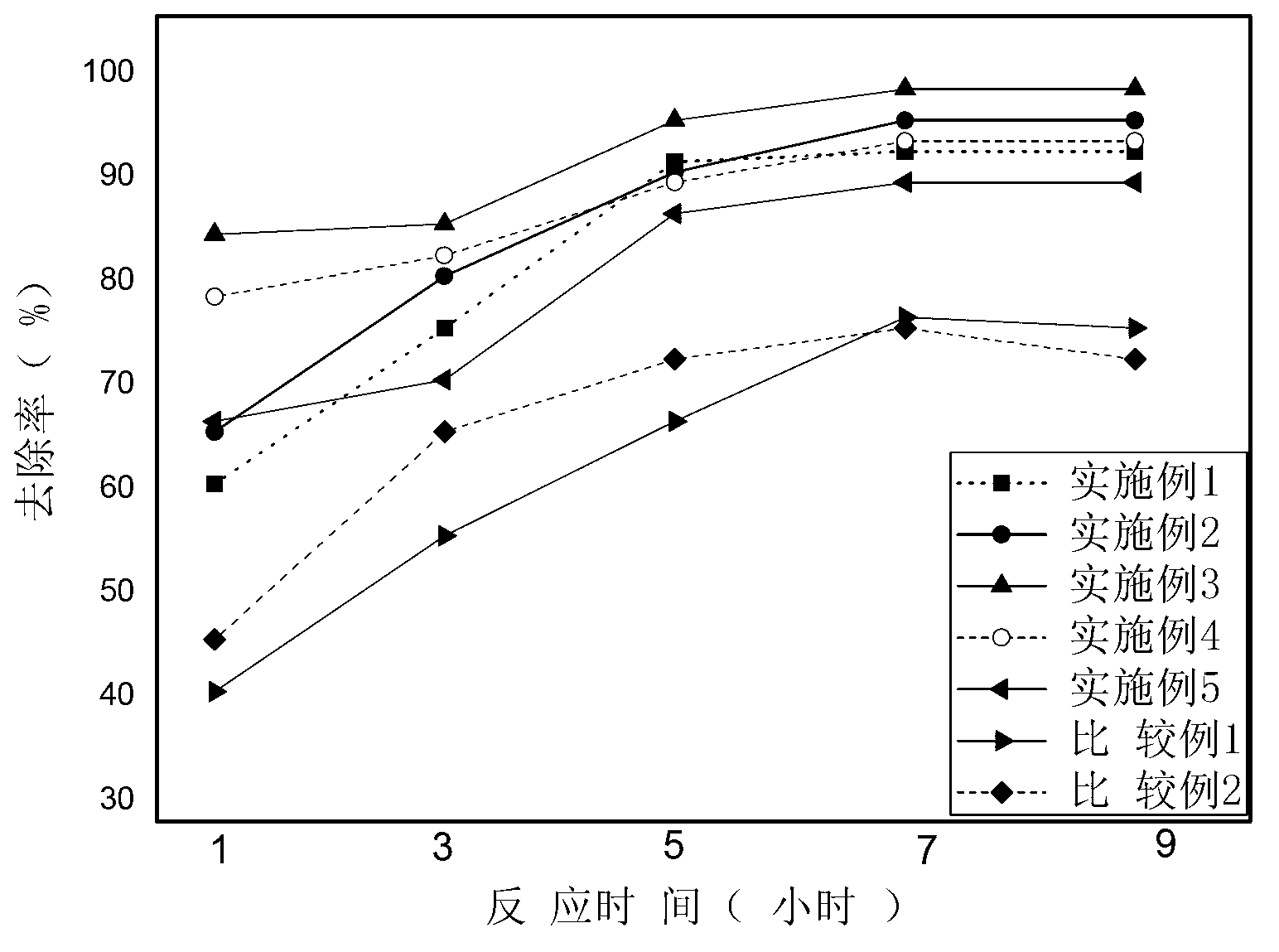

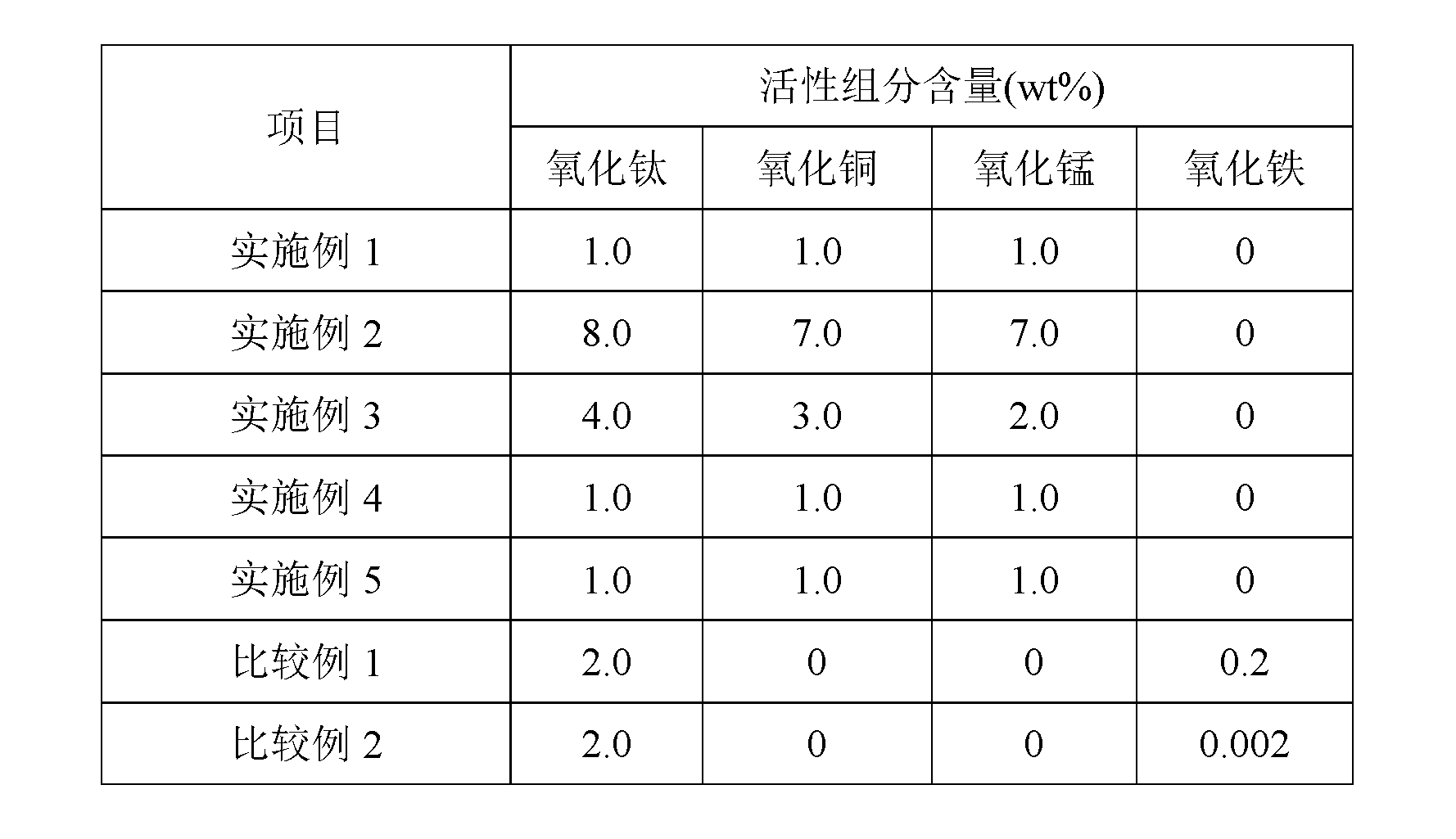

Method for preparing photocatalyst for treating petroleum pollutants in water

ActiveCN103007951ARemove applicableSimple preparation stepsWater/sewage treatment by irradiationMetal/metal-oxides/metal-hydroxide catalystsManganeseSlurry

The invention relates to a method for preparing a photocatalyst for treating petroleum pollutants in water. The method is characterized in that titanium dioxide and Cu and Mn oxides are taken as active ingredients and are loaded on a floating type foaming ceramic carrier through adopting a rolling load technology. The method comprises the following specific steps: (a) dissolving titanyl sulfate into deionized water, regulating the pH value to 7-10 by using a 5-25% ammonia solution, cleaning the obtained white precipitate centrifugally, mixing the white precipitate with the deionized water, pulping and regulating the pH value to 7-10 under a mixing condition by using H2O2 and HCl so as to obtain titanium sol; (b) dissolving manganese salt and copper salt into the deionized water, mixing with a permanganate solution, dripping a NaOH solution to regulate the pH value to 8-12 and spray-drying the obtained size to obtain catalyst precursor powder; and (c) adding foaming ceramic balls into a rotary granulator, spreading the catalyst precursor slowing under the rolling condition, spraying titanium sol to be used as an adhesion agent, carrying out roll coating, drying and calcinating to obtain a catalyst finished product.

Owner:CHINA NAT OFFSHORE OIL CORP +1

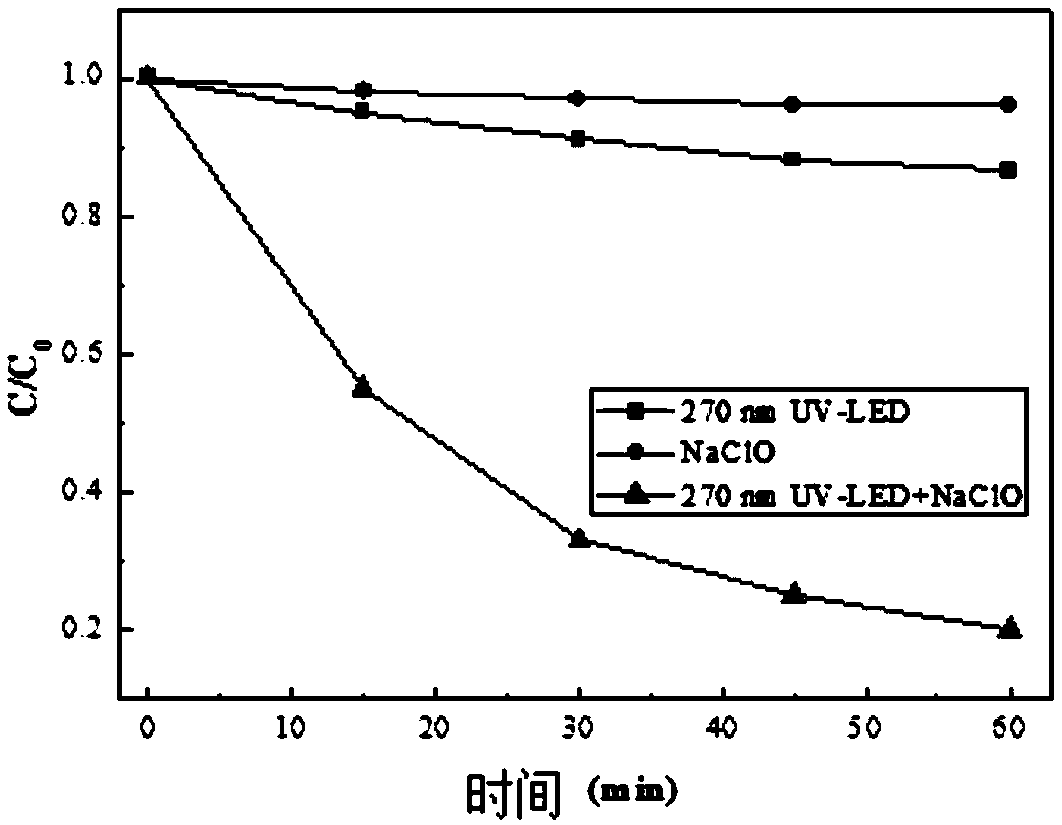

Method for removing brominated flame retardant in water body

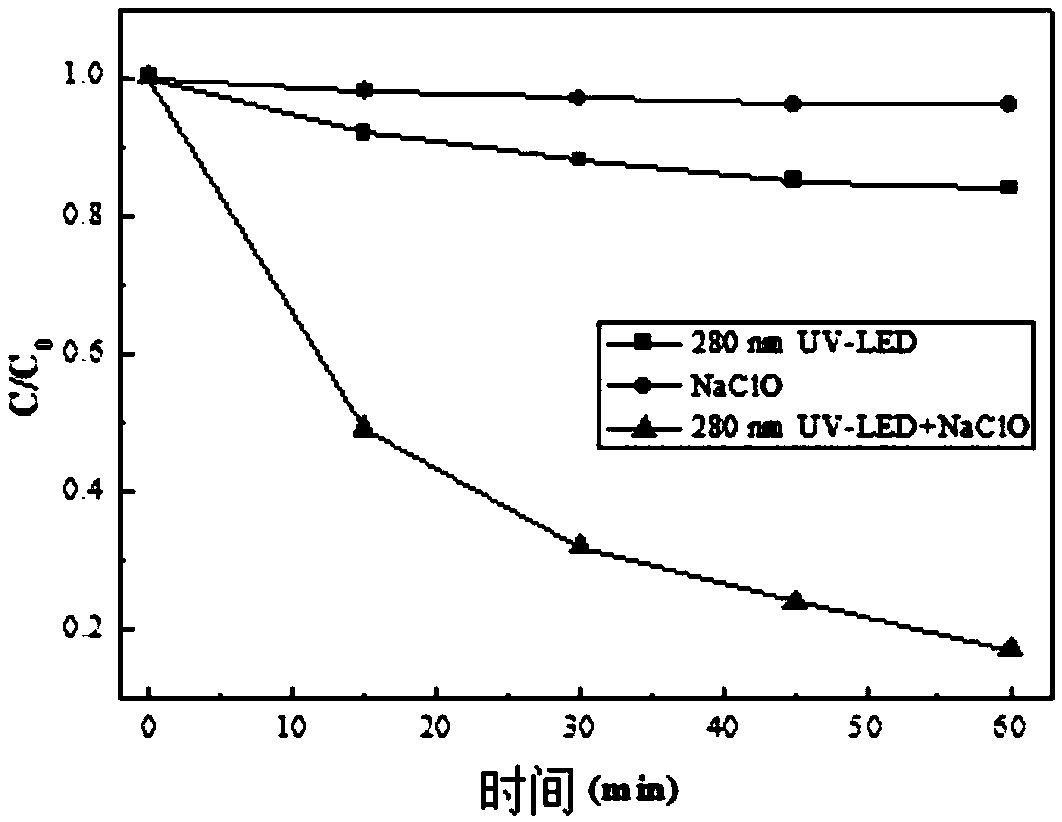

InactiveCN109368737ARemove applicableNo secondary pollutionWater/sewage treatment by irradiationWater contaminantsBromineChemistry

The invention relates to a method for removing a brominated flame retardant in a water body. An oxychlorination agent is added into wastewater containing the brominated flame retardant, irradiating isconducted through an ultraviolet light emitting diode, and chlorine radicals, hydroxyl radicals and the like are generated through short wave ultraviolet light in an activated mode to conduct oxidation removing on the brominated flame retardant. Compared with the prior art, the oxychlorination agent is adopted, the chlorine radicals are generated through the short wave ultraviolet light in the activated mode to conduct oxidation removing on organic matter, and a quick, efficient and environment-friendly novel technology for treating the brominated flame retardant in the wastewater is provided; and the method provided by the invention is environmentally friendly, secondary pollution is not generated, the good degrading effect can be achieved under the normal-temperature condition, operation is easy, and the method is suitable for removing organic pollutants such as the brominated flame retardant in the water body.

Owner:无锡市政公用环境检测研究院有限公司

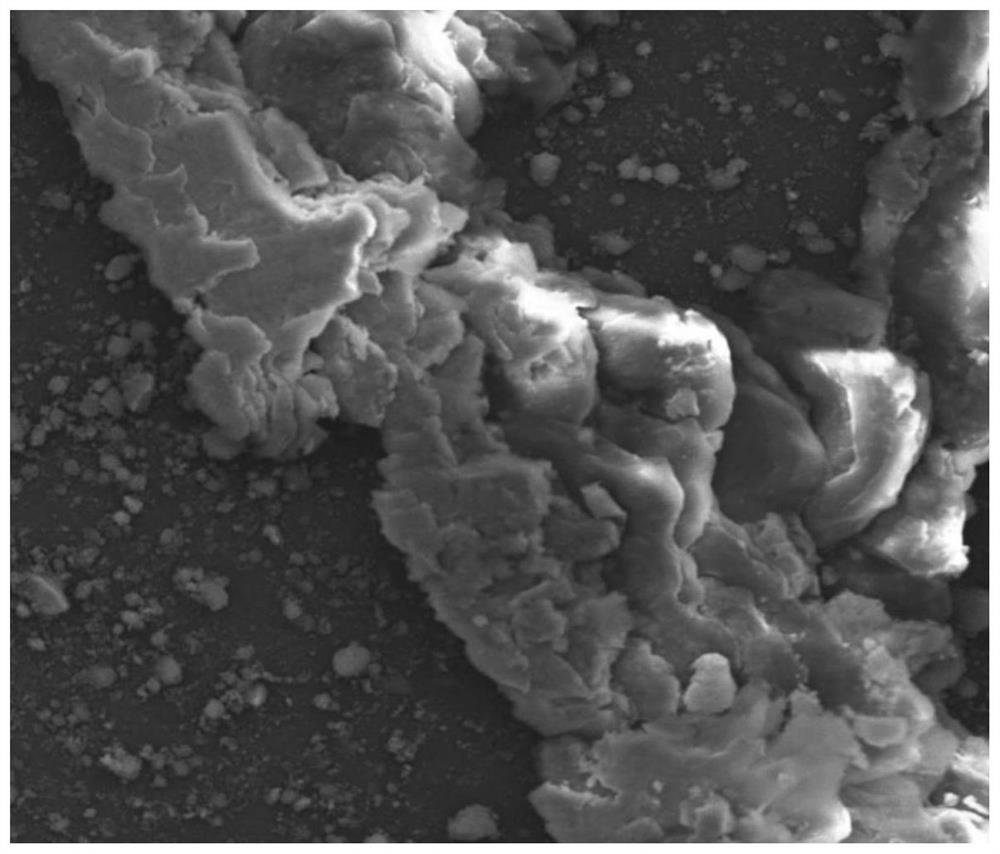

Layered composite hydrodesulphurization catalyst and preparation method

ActiveCN108144626AEfficient removalRemove applicableCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsVulcanizationHydrodesulfurization

The invention relates to a layered composite hydrodesulphurization catalyst and a preparation method. With nickel-molybdenum-tungsten composite sulfide as a catalytic active component and organicallymodified layered clay as a carrier, nickel-molybdenum-tungsten composite sulfide nanoparticles are prepared by adsorption, coordination, impregnation, drying, extrusion, roasting and vulcanization, the nickel-molybdenum-tungsten composite sulfide nanoparticles are uniformly dispersed into the layered structure of the clay, forming the layered composite hydrodesulphurization catalyst, wherein the molar ratio of nickel to molybdenum to tungsten is (4.5 to 5.5) to (0.15 to 1.2) to 1, and the total mass content of the nickel, molybdenum and tungsten elements in the layered composite hydrodesulphurization catalyst is 28 to 45 percent. The desulphurization efficiency of the novel, efficient and stable hydrodesulphurization catalyst is up to 99 percent or above, and the layered composite hydrodesulphurization catalyst is particularly applicable to the removal of sulfur in petroleum products.

Owner:NANJING UNIV OF TECH

Method for removing cells from human amnion

ActiveCN103114073BEfficient and thorough removalSo as not to damageArtificial cell constructsVertebrate cellsCell-Extracellular MatrixPhosphate

The invention discloses a method for removing cells from a human amnion. The method is characterized by comprising the following steps of: obtaining a clean semitransparent amnion, rinsing the semitransparent amnion by using a PBS (Phosphate Buffer Solution), soaking the semitransparent amnion in a comprehensive PBS liquid, shocking, rinsing the amnion by using the PBS after the amnion is taken out, successively soaking the amnion in steapsin / PBS liquid and deoxyribonuclease / PBS liquid for treatment, rinsing the amnion by using double-antibody / PBS liquid, taking out the decellularized amnion and putting the decellularized amnion in the PBS for preservation and standby. The method has the advantages that the cells are removed from the amnion in a manner that a surfactant is combined with steapsin and deoxyribonuclease, the cells can be prompted to be completely and efficiently removed from the amnion due to the combined use of the steapsin and the deoxyribonuclease, and meanwhile, the extracellular matrix is reserved to the maximum and is enabled to be free from damage.

Owner:杭州恩格生物医疗科技有限公司

A phosphorus removal agent containing inorganic minerals and its application method

ActiveCN104291420BEfficient removalRemove applicableOther chemical processesWater/sewage treatmentPhosphateSorbent

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

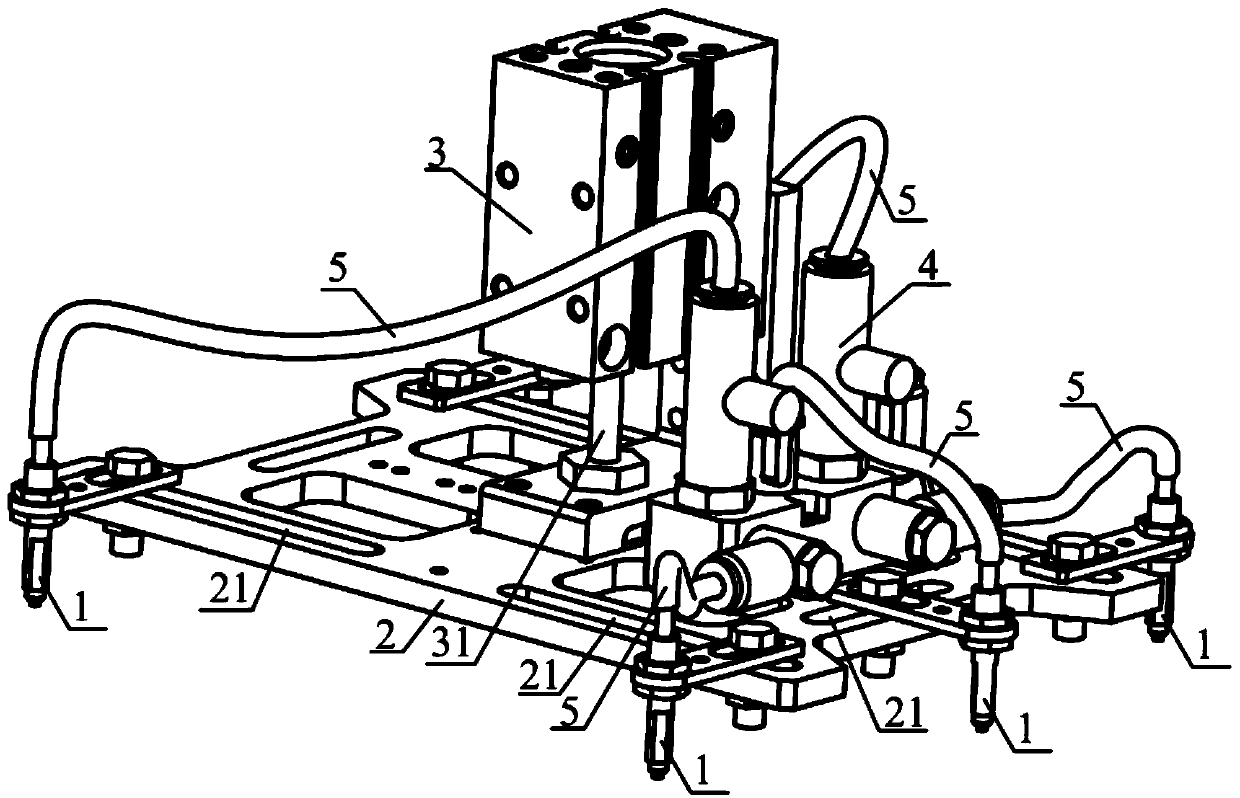

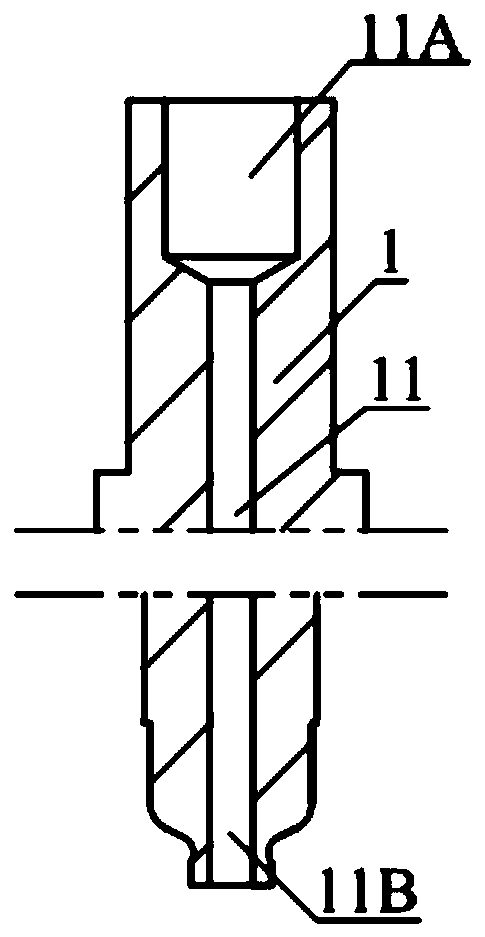

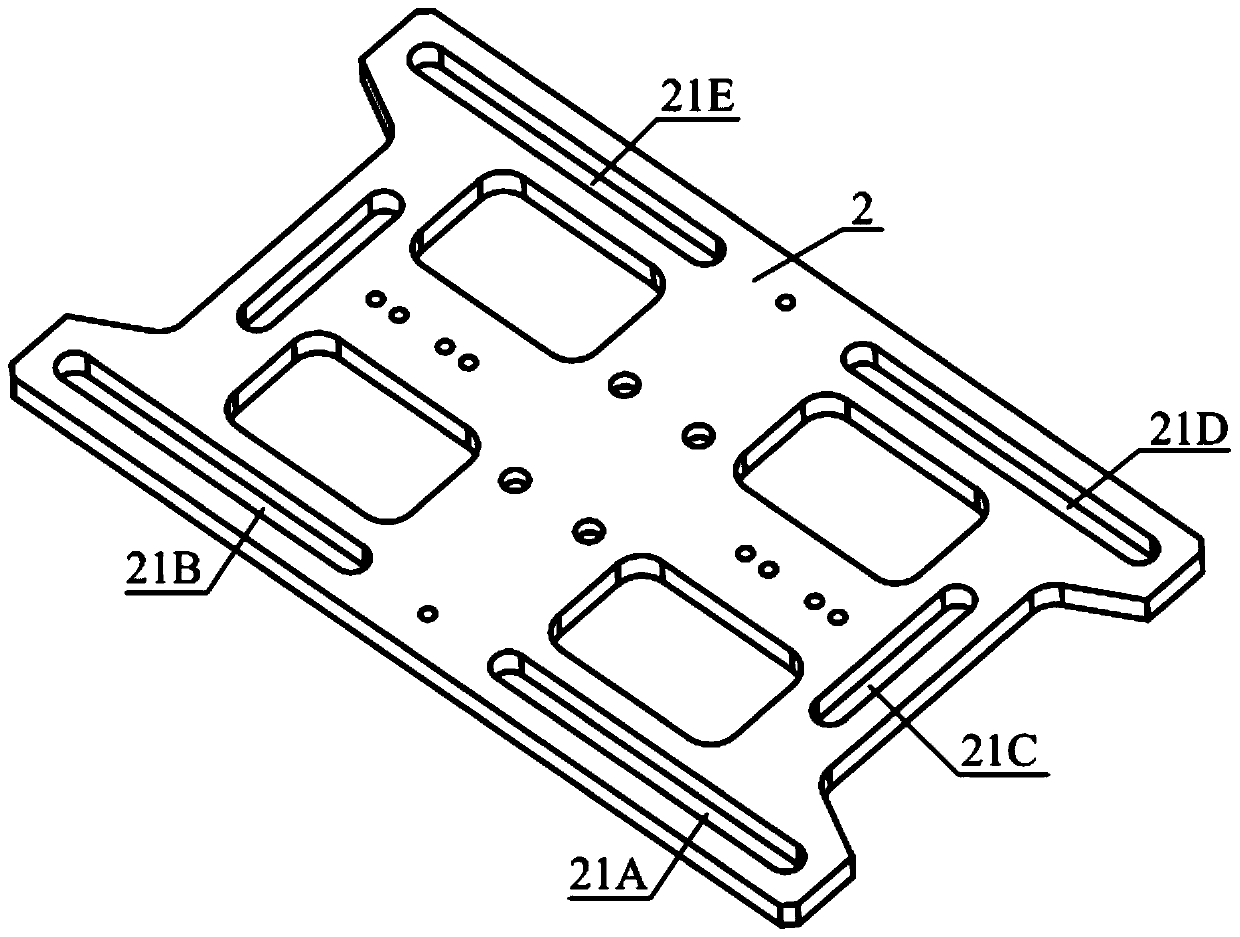

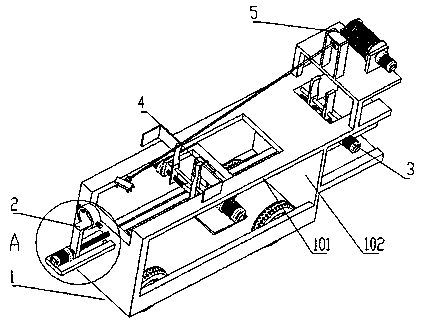

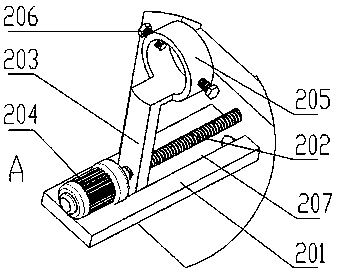

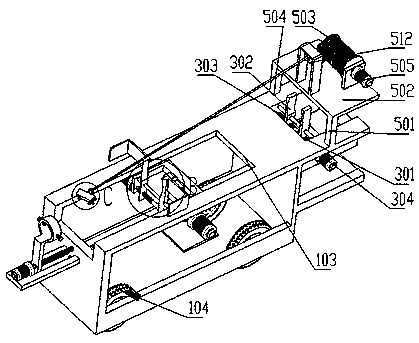

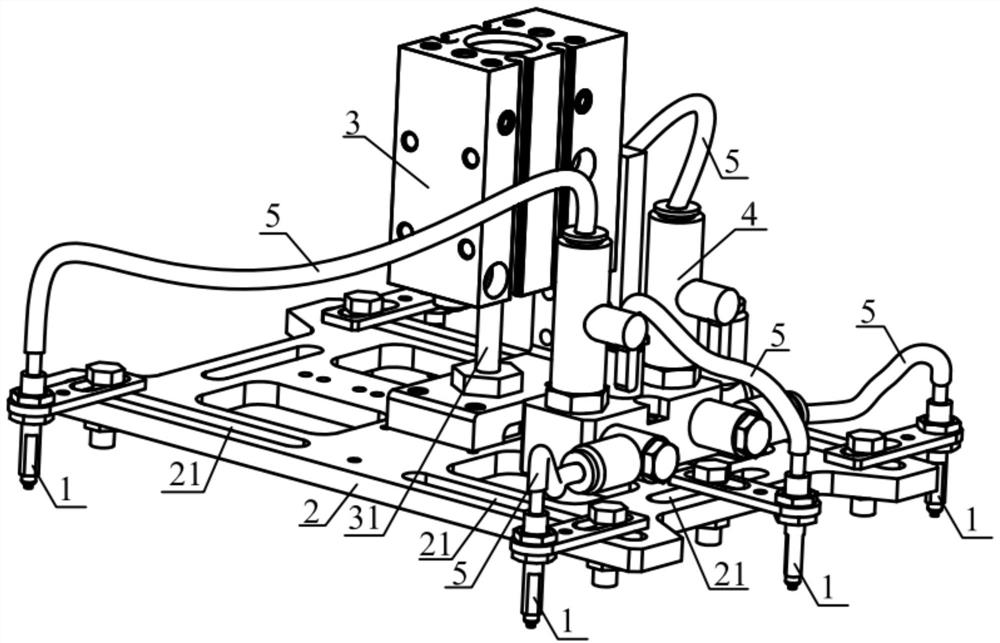

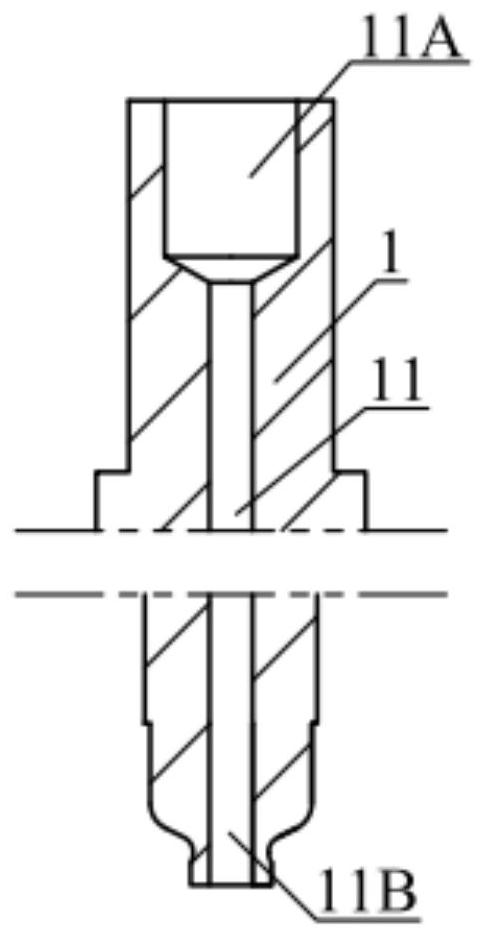

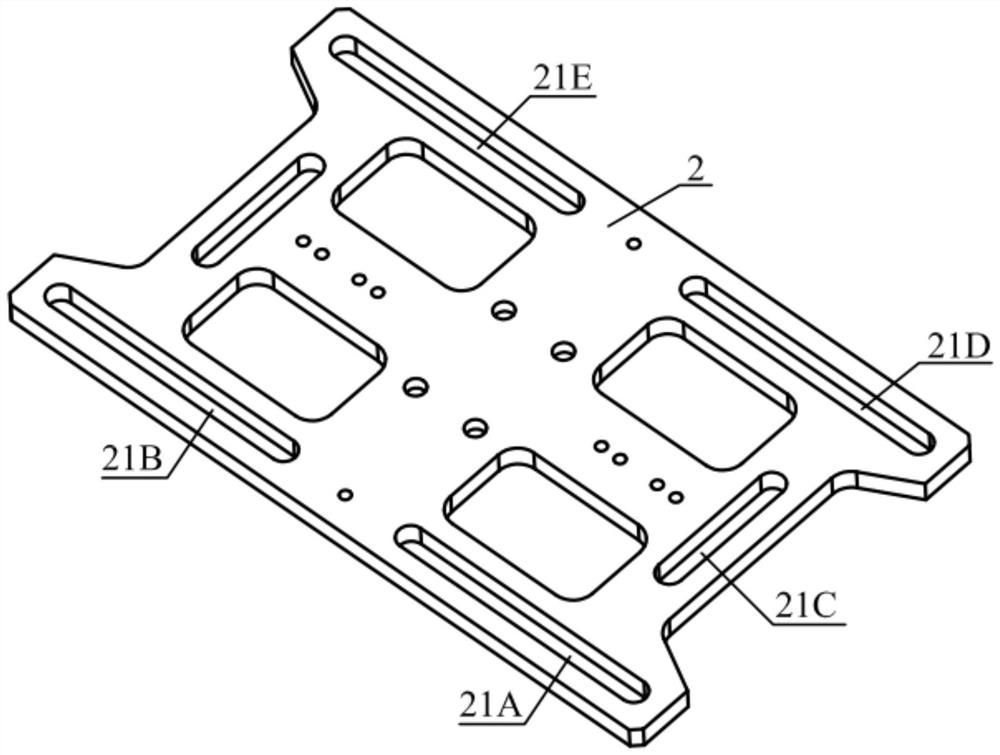

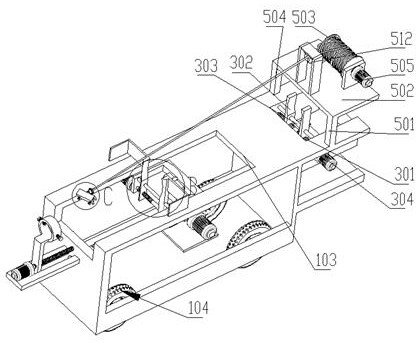

Waste wood removing system

The invention provides a waste wood removing system, and relates to the field of cutting. The waste wood removing system comprises suction cups, a suction cup installing plate, a lifting air cylinderand flow collecting blocks; the suction cup installing plate is provided with adjusting grooves, and the adjusting grooves penetrate through the two opposite long and wide faces of the suction cup installing; the suction cups are slidably installed in the adjusting grooves; the suction cups are provided with air guiding holes penetrating through the suction cups in the length direction of the suction cups, and the flow collecting blocks are connected with the corresponding ends of the air guiding holes of the suction cups through guiding pipes; and an output shaft of the lifting air cylinder is fixed to the suction cup installing plate. According to the waste wood removing system, the problems that an existing waste wood removing system can not be suitable for removing waste wood in special shapes and is narrow in application range.

Owner:HANS LASER TECH IND GRP CO LTD

Polybenzoxazine-based derived carbon material for adsorbing carbonyl sulfide and preparation method and application thereof

PendingCN113457627AImprove adsorption capacityRemove applicableProductsCarbon compoundsCarbonyl sulfideAdsorption effect

The invention discloses a polybenzoxazine-based derived carbon material for adsorbing carbonyl sulfide and a preparation method and application thereof. The preparation method of the polybenzoxazine-based derived carbon material comprises the steps that an amine compound serves as a curing agent, a polyoxyethylene-polyoxypropylene-polyoxyethylene triblock copolymer P127 serves as a soft template agent, in the presence of the curing agent and the soft template agent, a phenol compound and an aldehyde compound are subjected to a one-step polymerization reaction, an obtained polymer is subjected to high-temperature carbonization pyrolysis, and the preparation is completed. The polybenzoxazine-based derived carbon material has the advantages of large specific surface area, developed micropores, high mechanical strength and the like, and has a relatively good adsorption effect on carbonyl sulfide in coke oven gas. The method has the advantages of simple preparation method, low raw material cost, no by-product and the like, and has potential industrial application value.

Owner:ZHEJIANG UNIV OF TECH

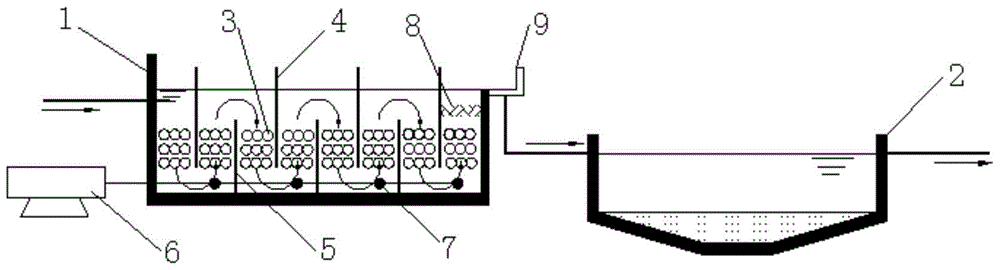

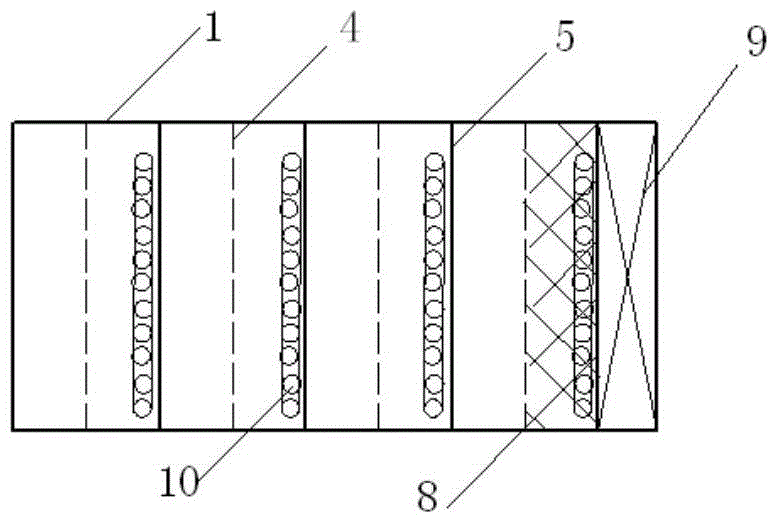

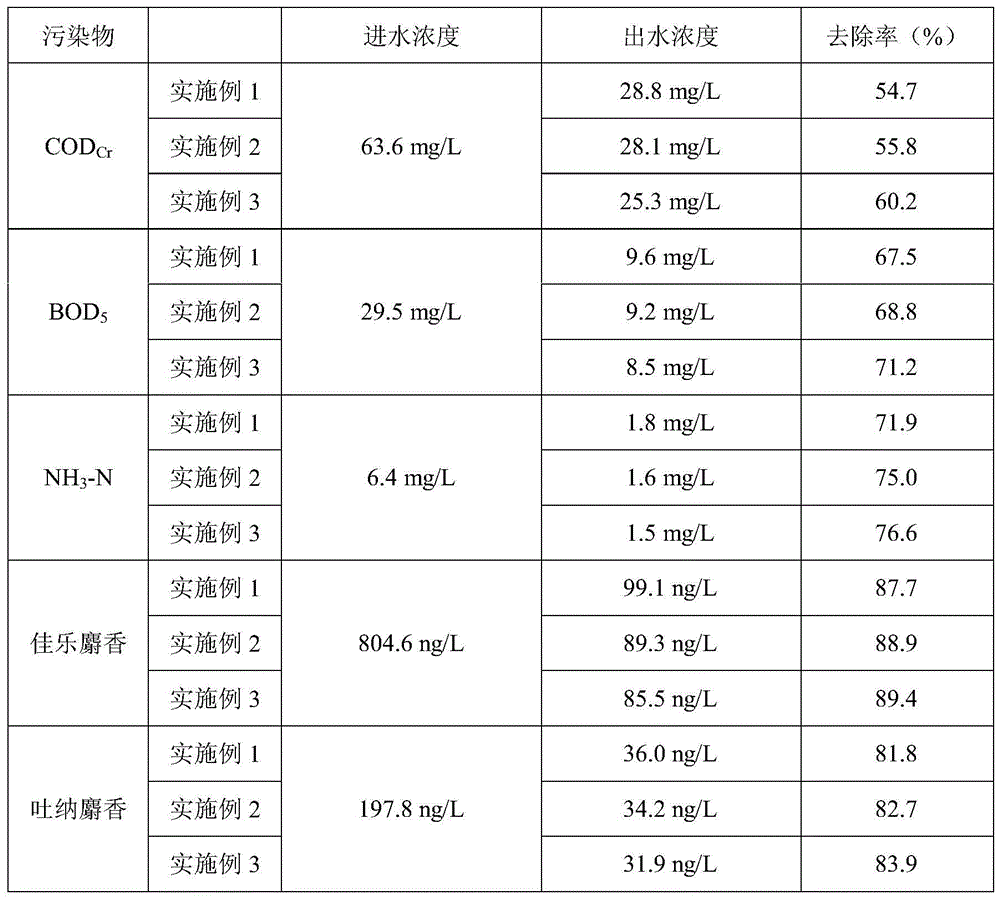

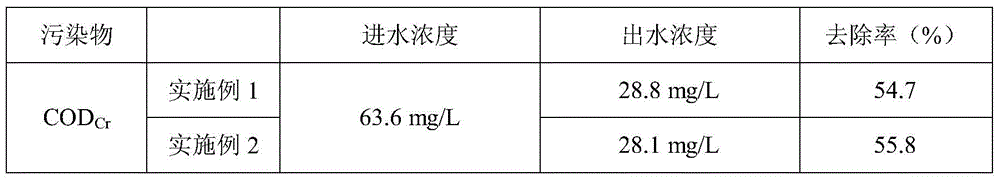

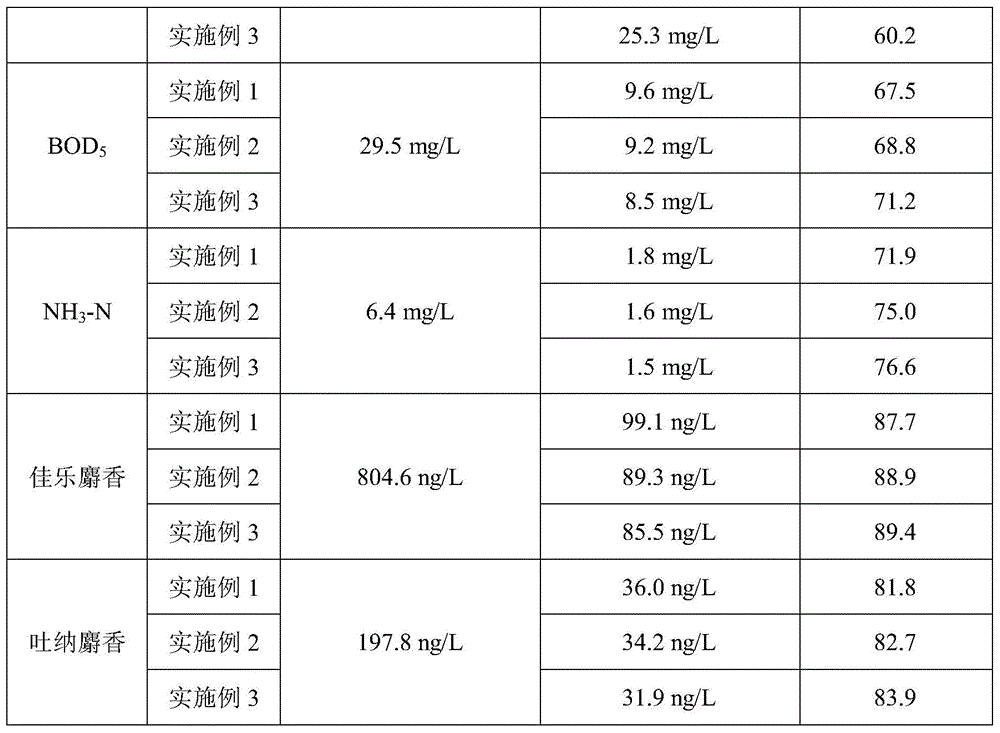

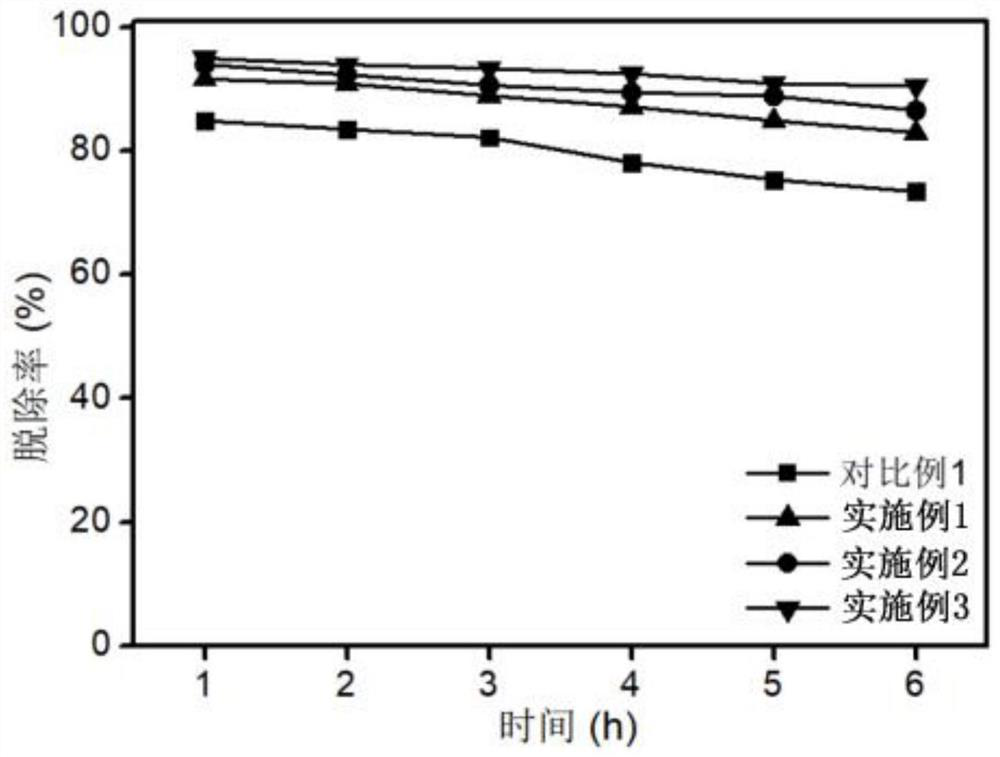

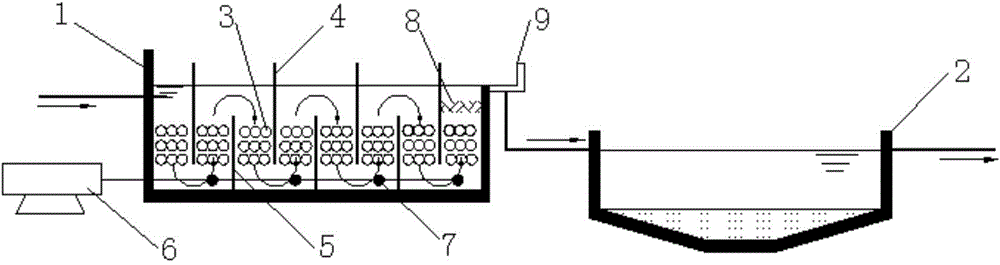

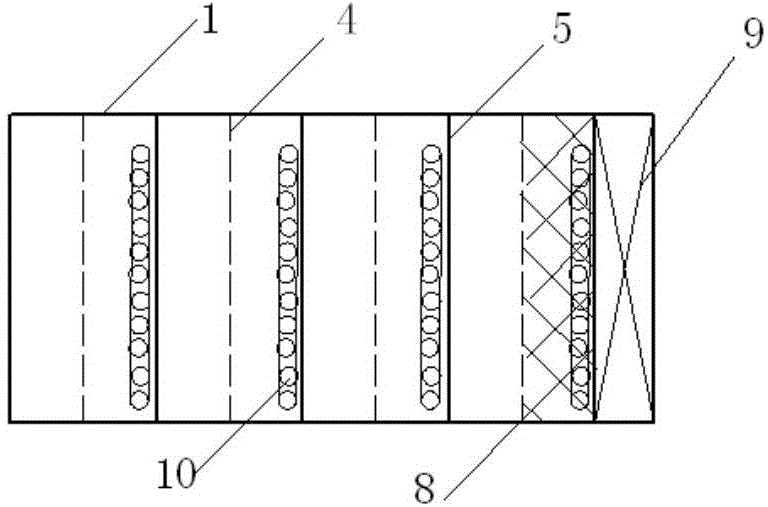

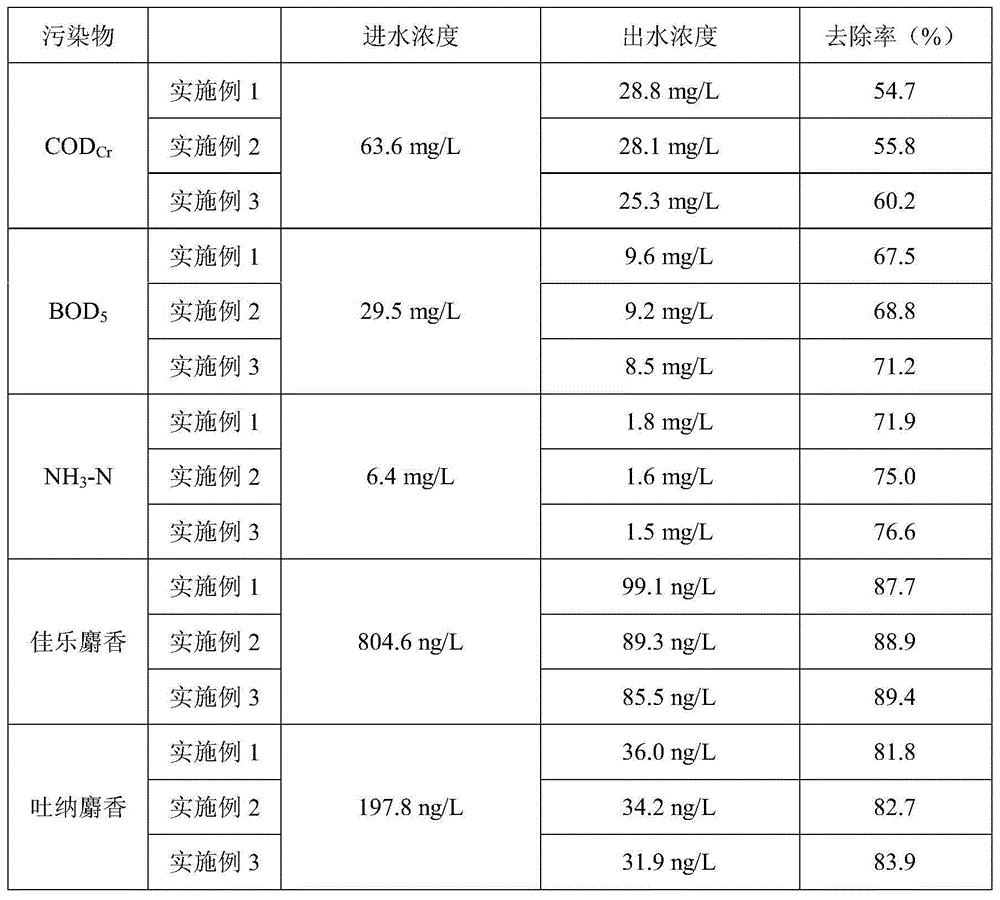

A device for removing synthetic musk in sewage

InactiveCN104803551BImprove efficiencyImprove removal efficiencyTreatment using aerobic processesMultistage water/sewage treatmentSynthetic muskSewage

The invention provides a device for removing synthetic musk in sewage. The device comprises an aerobic treatment device and a sedimentation device, wherein the aerobic treatment device comprises a plurality of small microbial spheres arranged in the aerobic treatment device, a plurality of baffles vertically arranged in the aerobic treatment device, an aeration device located at the bottom of the aerobic treatment device as well as a carrier separator and an effluent weir which are located at a water outlet of the aerobic treatment device. Under the action of aeration and blockage with the baffles, the sewage sequentially passes through bottom ends and top ends of the adjacent baffles to form baffling flow which reciprocates up and down, and contact time with the plurality of small microbial spheres is prolonged; the small microbial spheres are spheres containing bacillus subtilis and a curing embedding agent, the curing embedding agent is used for adsorbing the synthetic musk in the sewage, and the bacillus subtilis is used for degrading the adsorbed synthetic musk; the degraded sewage is subjected to sedimentation treatment in the sedimentation device, and a supernatant is treated effluent.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

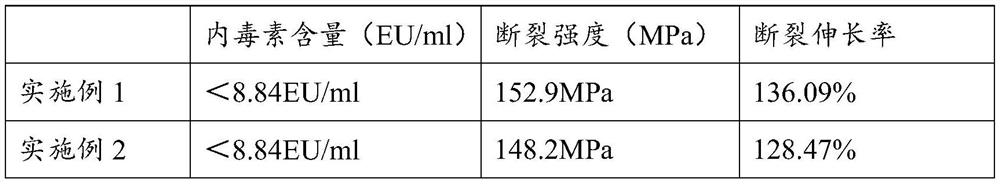

Method for removing endotoxin in bacterial cellulose

ActiveCN113957738AEasy to purifyLow endotoxin contentFats/resins/pitch/waxes removal in pulpAgainst vector-borne diseasesMicrobiologySodium hydroxide

The invention relates to the technical field of medical instruments, in particular to a method for removing endotoxin in bacterial cellulose. The method comprises the following steps: (1) soaking sliced bacterial cellulose in a sodium hydroxide solution, and replacing the sodium hydroxide solution for soaking for multiple times; (2) soaking bacterial cellulose in an ethanol solution, and dissolving endotoxin in the porous structure; (3) adding a sodium hydroxide solution and a polysulfone resin polymer with positive charges into the bacterial cellulose treated in the step (2); and (4) soaking the treated bacterial cellulose in water for injection until the pH value is 7 + / -1. According to the method, the endotoxin in the bacterial cellulose is removed, the purification process of the bacterial cellulose is accelerated, the mechanical property and physical and chemical aspects of the bacterial cellulose are not affected, and the endotoxin content of the obtained bacterial cellulose is far smaller than the specified content.

Owner:SHAN DONG NAMEIDE BIOTECHNOLOGY CO LTD

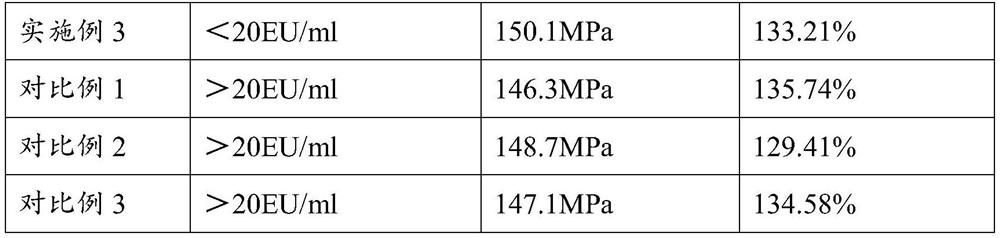

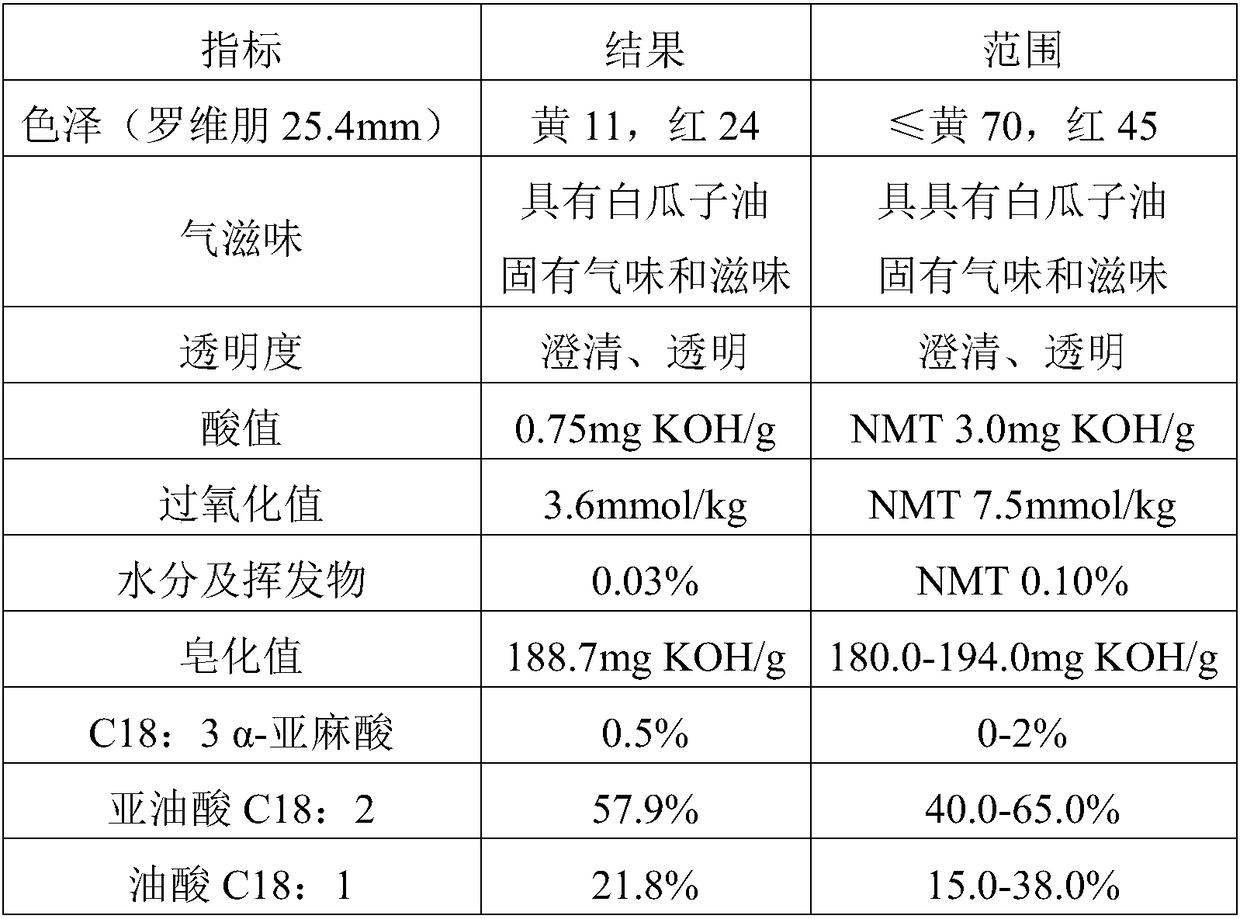

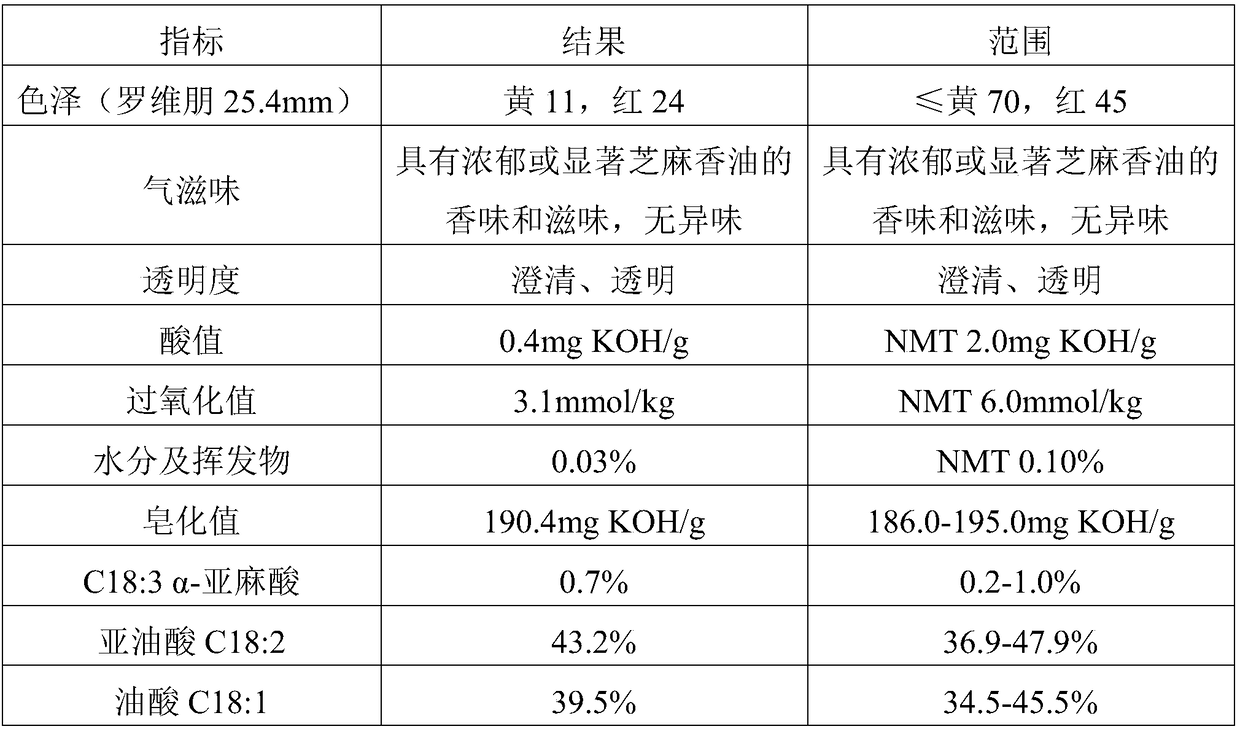

Method for removal of vegetable oil precipitate after pressing

PendingCN108485809AShort reaction timeImprove reaction efficiencyFatty-oils/fats refiningOil and greaseVegetable oil

Belonging to the technical field of vegetable oil processing, the invention relates to a method for removal of vegetable oil precipitate after pressing. The method includes: subjecting pressed vegetable oil to coarse filtration, then adding a nonionic surfactant for microwave radiation treatment, conducting cooling and filtering, and removing precipitate. The vegetable oil obtained by the method provided by the invention has good quality, and is free of precipitate or turbid phenomenon after placement at 0-6DEG C for 1-3 months.

Owner:SANMARK CORP

A method for removing complexed heavy metal ions in water

ActiveCN107364985BEfficient removalEffective network breakWater treatment compoundsWater contaminantsReagentHeavy metals

The invention relates to the technical field of wastewater treatment, in particular to a method for removing complexed heavy metal ions in water. The invention provides a method for removing complexed heavy metal ions in water, comprising the following steps: 1) reacting the water containing complexed heavy metal ions with a heavy metal replacement reagent, and then adding a heavy metal scavenger. The method for removing complexed heavy metal ions in the water body is simple, easy to operate, low in cost, has a wide range of removable heavy metal ion concentrations, and can be efficiently removed, and the concentration of heavy metal ions in effluent water is less than 0.1 ppm.

Owner:CHONGQING MOLECULAR WATER SYST

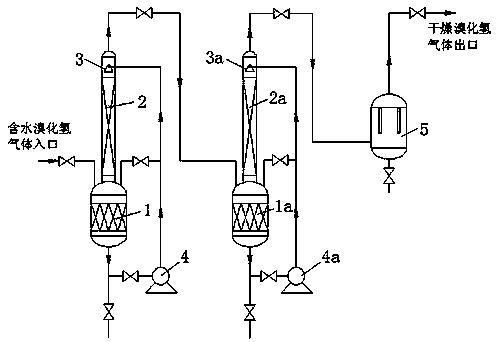

A kind of method of drying hydrogen bromide gas

ActiveCN103318843BRemove applicableImprove dehydration efficiencyBromine/hydrogen-bromidePhosphorus tribromideEnvironmental engineering

A method of dried bromide gases belongs to the field of inorganic chemical and hydrogen gaseous purification technology.This method of dried bromide gases allows the hydrogen gases containing moisture to enter the drying tower of the filler from the bottom, and connect the liquid inorganic bromide, triglycetic phosphorus and hydrogen bromide from the top of the drying tower of the fillerThe gas is in the inverse flow of the drying tower in the drying tower. The two -stage series of filler drying tower is dried. After passing the dehomato, the water content is lower than 20 ppm dry bromide gases. At the same timeEssenceTrilyarized phosphorus liquids can be used circularly, but after the concentration is less than 80%, vacuum distillation can be used to recycle and use it.This method is more efficient than the current method. The dehydration efficiency is higher. The water content of hydrogenation can be less than 20PPM. It is suitable for the case where the hydrogen gaseous pressure is relatively small in the production process. It is especially suitable for bromine bromine bromine in hydrogen.The removal of water in hydrogen gases.

Owner:中昊光明化工研究设计院有限公司

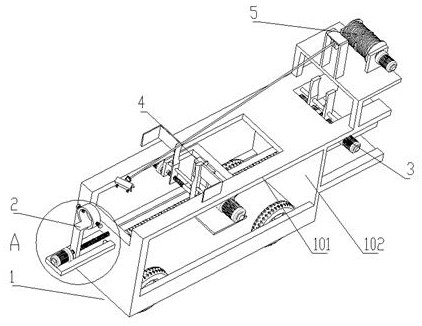

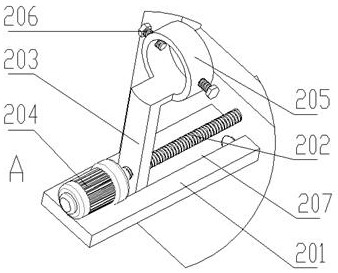

Auxiliary robot for cable construction

ActiveCN111541133AEasy to cutEasy to scratchLine/current collector detailsElectric machineryStructural engineering

The invention provides an auxiliary robot for cable construction, and belongs to the technical field of cable construction. The technical scheme is as follows: the robot comprises a rack, the rack comprises a top plate and vertical plates arranged at the two ends of the top plate, a first screw rod is rotationally arranged between the two vertical plates, a rectangular opening is formed in the position, corresponding to the first screw, of the top plate, a first moving plate is arranged on the first screw rod in a threaded connection manner, the first moving plate penetrates through a limitingrod arranged between the two vertical plates; the limiting rod is located above the first screw rod, a cutting mechanism is arranged on the first moving plate, a steel armor jacking mechanism is arranged on the outer side of any vertical plate, a cable clamp is arranged on the outer side of the other vertical plate, and the end, close to the cable clamp, of the first screw rod extends out of thevertical plate to be connected with a first motor with a speed reducer. The auxiliary robot has the advantages that the robot can assist workers in removing the outer sheath of a cable, so that the workload of construction personnel is reduced, and the construction progress is improved.

Owner:中铁十四局集团电气化工程有限公司

A waste material removal system

The invention provides a waste material removal system, which relates to the field of cutting. The waste material removal system includes: a suction cup, a suction cup mounting plate, a lifting cylinder and a collector block. An adjustment slot is provided on the suction cup mounting plate, and the adjustment slot runs through two opposite long and wide surfaces of the suction cup mounting plate. The suction cup is slidably installed in the adjusting groove. The suction cup is provided with an air guide hole passing through the suction cup in the length direction of the suction cup, and the collector block is connected to one end of the air guide hole of the suction cup through a conduit. The output shaft of the lift cylinder is fixed on the suction cup mounting plate. The invention can solve the problem that the existing waste material removal system is suitable for removing waste material of a specific shape and has a narrow application range.

Owner:HANS LASER TECH IND GRP CO LTD

An auxiliary robot for cable construction

ActiveCN111541133BEasy to scratchAvoid harmLine/current collector detailsReduction driveElectric machinery

The invention provides an auxiliary robot for cable construction, which belongs to the technical field of cable construction. Its technical solution is: including a frame, the frame includes a top plate and vertical plates arranged at both ends of the top plate, a screw one is rotated between the two vertical plates, and a screw on the top plate corresponding to the screw one The position is provided with a rectangular opening, and the screw rod one is provided with a moving plate one through threaded connection, and the moving plate one passes through a limit rod arranged between the two vertical plates, and the limit rod is located on the Above the screw rod one, a cutting mechanism is provided on the moving board one, a steel armor tightening mechanism is provided on the outside of any of the vertical boards, and a cable clamp is provided on the outside of the other vertical board, and the screw rod one is close to the One end of the cable clamp stretches out from the vertical plate and is connected with the motor with the reducer. The beneficial effect of the invention is that it can assist manual removal of the outer sheath of the cable, so as to reduce the work burden of construction personnel and improve the construction progress.

Owner:中铁十四局集团电气化工程有限公司

Iron-based catalyst for enhanced ozone oxidation of organic pollutants and preparation method thereof

ActiveCN110075845BIncrease profitAchieve removalWater treatment compoundsSpecific water treatment objectivesPtru catalystFerric oxyhydroxide

Owner:CHONGQING UNIV

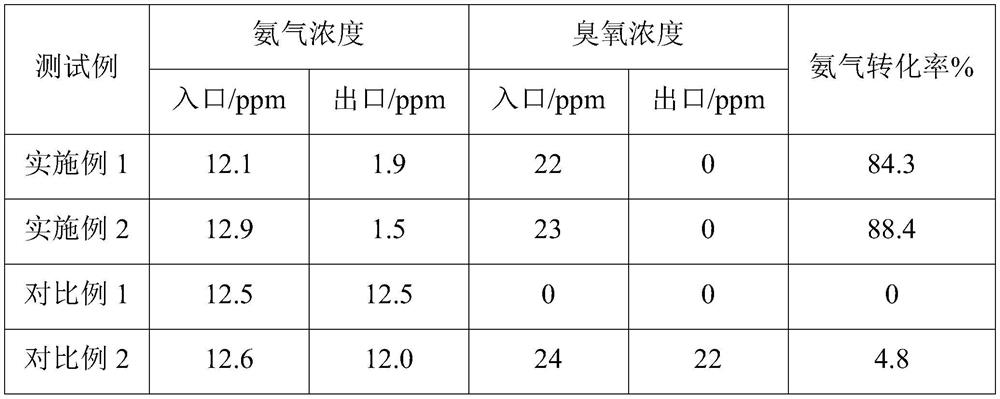

Ozone oxidation ammonia gas catalyst, preparation method and application thereof

ActiveCN113019423ALittle effect on catalytic performanceImprove stabilityMolecular sieve catalystsHeterogenous catalyst chemical elementsChemical industryPtru catalyst

The invention relates to an ozone oxidation ammonia gas catalyst as well as a preparation method and application thereof, and belongs to the technical field of environment-friendly chemical industry. The catalyst is composed of a carrier, an active component and an auxiliary component. The carrier is a molecular sieve or activated carbon. The active component is copper oxide and / or manganese oxide. The auxiliary components are ferric oxide and titanium oxide. The preparation method of the catalyst comprises the following steps: adding salt of active components and and ferric salt into water, conducting stirring and dissolving to obtain a metal salt solution, adding a carrier and titanium dioxide into the solution, continuously conducting stirring, dropwise adding a precipitator into the solution to co-precipitate the salt of the active components and ferric salt, stopping dropwise adding the precipitator when the pH value of the metal salt solution reaches 7.5-8.3, washing the obtained precipitate with water, conducting filtering, drying and molding, and then conducting roasting at 300-450 DEG C for 3-6 hours to obtain the catalyst. The catalyst is combined with ozone for use, and can be applied to ammonia gas purification.

Owner:718TH RES INST OF CHINA SHIPBUILDING INDAL CORP

A method for removing synthetic musk in sewage

InactiveCN104817160BImprove efficiencyImprove removal efficiencyTreatment using aerobic processesSustainable biological treatmentSynthetic muskMicroorganism

The invention provides a method for removing synthesis musk in sewage, which comprises the following steps: introducing synthesis musk-containing sewage in an aerobic processing apparatus having several microorganism balls, prolonging the contact time of the synthesis musk-containing sewage and several microorganism balls units, fully degrading the synthesis musk by several microorganism balls units, then introducing the degraded sewage in a deposition apparatus for sludge deposition treatment to obtain a supernatant; wherein each microorganism balls unit is composed of several microorganism balls, each microorganism ball is the ball containing bacillus subtilis and a cured embedding agent, each microorganism ball uses the cured embedding agent for absorbing the synthesis musk in sewage and uses the bacillus subtilis for degrading the attached synthesis musk. The method is used for deeply processing the sewage, and the synthesis musk content in the processed water is low, and clearance rate is high.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Adsorbing material for removing organic sulfur in coke oven gas and application of adsorbing material

ActiveCN113070039AImprove removal effectImprove adsorption capacityOther chemical processesGas purification with selectively adsorptive solidsSodium acetateCarbonyl sulfide

The invention discloses an adsorbing material for removing organic sulfur in coke oven gas and application of the adsorbing material. The adsorbing material is prepared by the following steps: by taking activated carbon as a carrier, carrying out in-situ reaction on N-methylimidazole, bromoethane and anhydrous sodium acetate on the activated carbon to generate 1-ethyl-3-methylimidazole acetate ionic liquid so as to achieve loading of the 1-ethyl-3-methylimidazole acetate ionic liquid on the activated carbon in situ. The adsorbing material can simultaneously remove carbonyl sulfide and carbon disulfide in coke oven gas at a low temperature (20-50 DEG C), is used for removing organic sulfur in coke oven gas, has the advantages of pertinence, simple process, convenience in operation, low operation cost, no corrosion to equipment and the like, and has potential industrial application value.

Owner:ZHEJIANG UNIV OF TECH

Device for removing synthetic musk in sewage

InactiveCN104803551AImprove efficiencyImprove removal efficiencyTreatment using aerobic processesMultistage water/sewage treatmentSynthetic muskEngineering

The invention provides a device for removing synthetic musk in sewage. The device comprises an aerobic treatment device and a sedimentation device, wherein the aerobic treatment device comprises a plurality of small microbial spheres arranged in the aerobic treatment device, a plurality of baffles vertically arranged in the aerobic treatment device, an aeration device located at the bottom of the aerobic treatment device as well as a carrier separator and an effluent weir which are located at a water outlet of the aerobic treatment device. Under the action of aeration and blockage with the baffles, the sewage sequentially passes through bottom ends and top ends of the adjacent baffles to form baffling flow which reciprocates up and down, and contact time with the plurality of small microbial spheres is prolonged; the small microbial spheres are spheres containing bacillus subtilis and a curing embedding agent, the curing embedding agent is used for adsorbing the synthetic musk in the sewage, and the bacillus subtilis is used for degrading the adsorbed synthetic musk; the degraded sewage is subjected to sedimentation treatment in the sedimentation device, and a supernatant is treated effluent.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

A kind of attapulgite clay composite catalyst for removing formaldehyde and its preparation method and application

ActiveCN108212148BLarger than surfaceStable structureDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCelluloseMeth-

The invention discloses an attapulgite clay composite catalyst for formaldehyde removal and its preparation method and application. The composite catalyst mainly includes a composite carrier, a precious metal component and an active metal component. The composite carrier is mainly composed of the following raw materials in parts by weight. Made of: 30-45 parts of attapulgite clay, 25-35 parts of metal oxides, 8-15 parts of polybutyl acrylate, 3-8 parts of methylcellulose, 5-10 parts of fatty acid diethanolamide, phthalate 5-10 parts of formic acid; the added amount of the precious metal component accounts for 0.0005-0.001% of the mass of the attapulgite clay based on the mass of the precious metal element, and the added amount of the active metal component accounts for the mass of the attapulgite clay based on the mass of the active metal element 0.01‑0.02%. The composite catalyst prepared by the invention has a large specific surface, stable structure, and good photocatalytic performance. It can effectively remove formaldehyde in the environment. The preparation method is simple and convenient, and can be applied to industrial production.

Owner:国盾(山东)知识产权运营管理有限公司

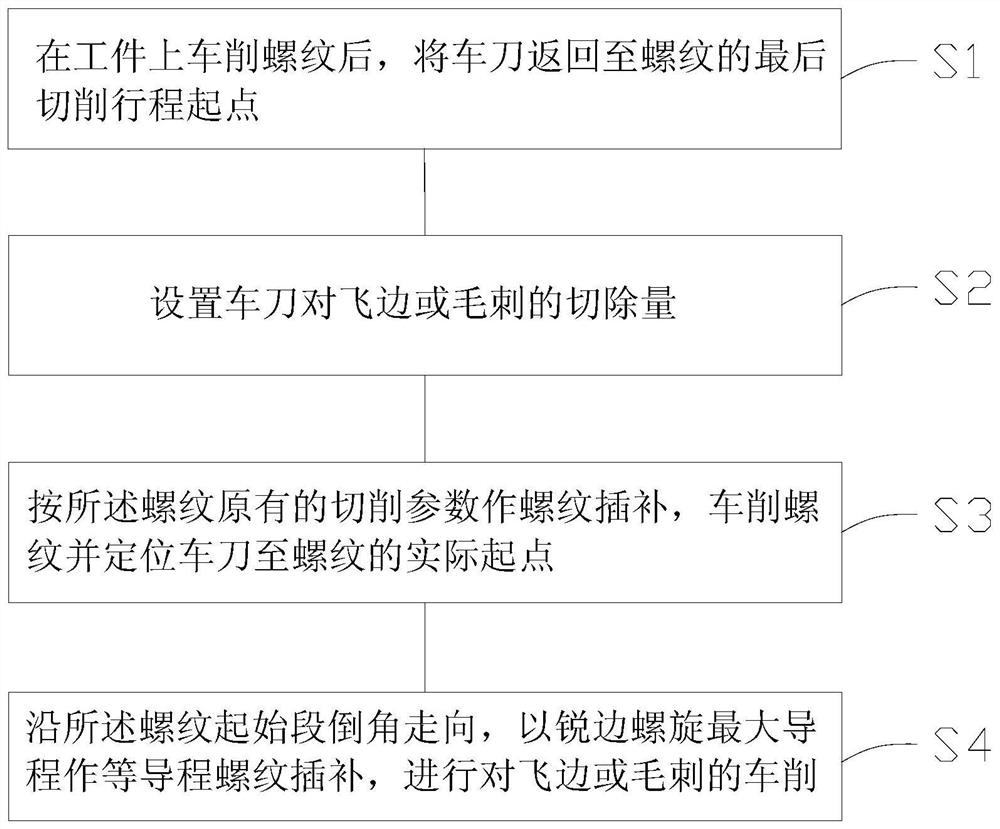

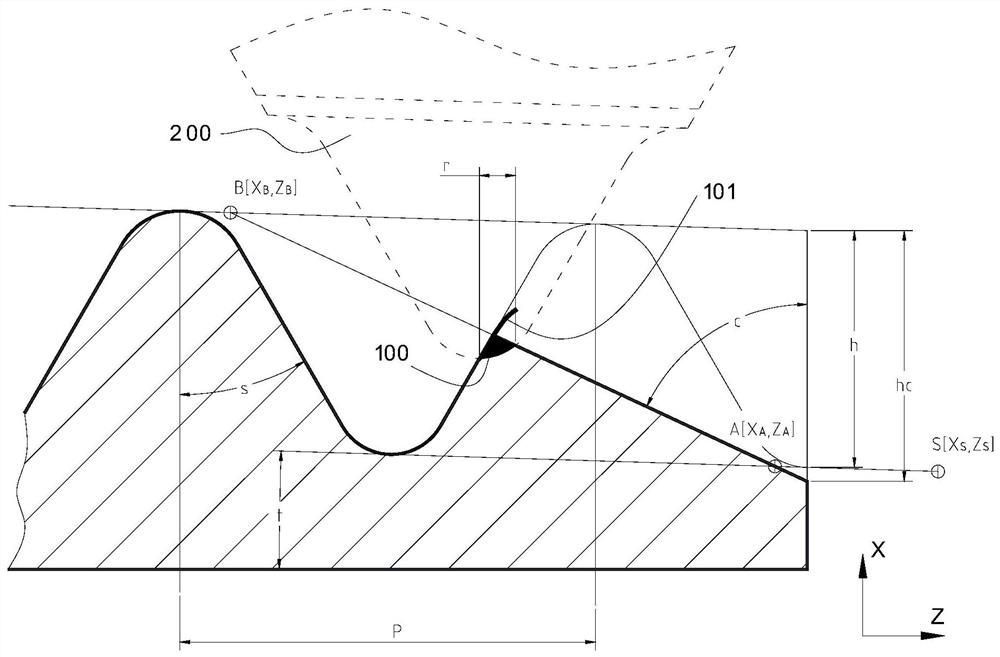

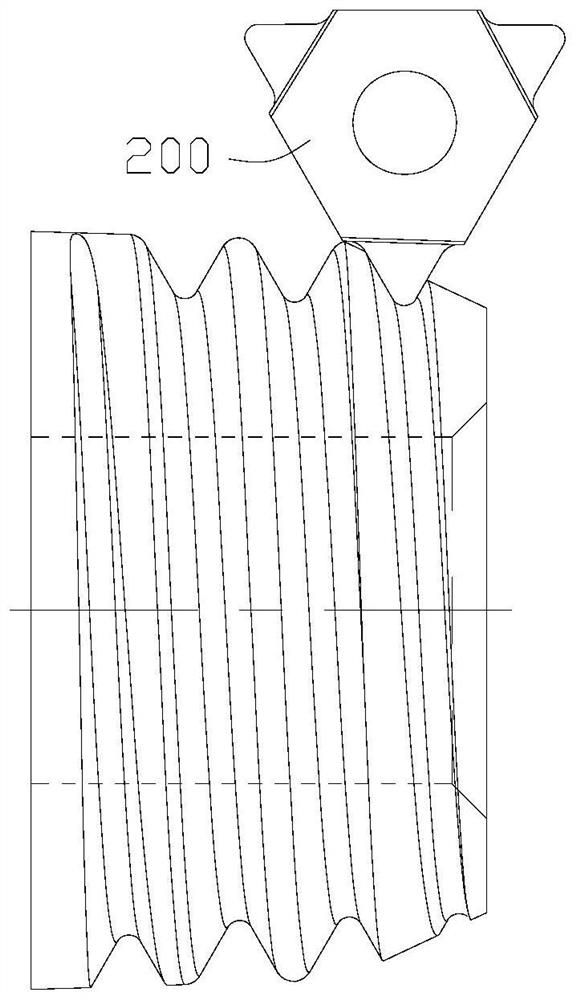

A method for removing flash or burrs at the initial section of a workpiece thread by a numerically controlled lathe

ActiveCN110711909BAchieve removalAccurate removalThread cutting machinesScrew threadIndustrial engineering

The invention provides a method for removing burrs or burrs at the beginning of a thread of a workpiece by a numerically controlled lathe, comprising the following steps: after turning a thread on a workpiece, returning a turning tool to the starting point of the final cutting stroke of the thread; The amount of burr removal; thread interpolation is performed according to the original cutting parameters of the thread, the thread is turned and the turning tool is positioned to the actual starting point of the thread; the chamfering direction along the starting section of the thread is based on the maximum lead of the sharp-edged helix. Equal lead thread interpolation for turning burrs or burrs. The method for removing the burrs or burrs at the beginning of the thread of the workpiece by the CNC lathe can accurately remove the foundations of the burrs or the burrs, and does not need to change the tool, thus saving the trouble of changing the tool.

Owner:BEIBU GULF UNIV

A Method for Quickly Removing Thermal Spray Coatings

ActiveCN104858792BIncrease pressureShort removal timeAbrasion apparatusMetal coatingThermal spraying

A method for quickly removing a thermal spray coating, the sandblasting material adopts alloy sand with a particle size of 0.5-5.0mm, special-shaped alloy sand with an aspect ratio of 1.0-5.0 and ceramic sand with a mesh of 10-50, the alloy sand, special-shaped The mass ratio of the three raw materials of alloy sand and ceramic sand is (1~4):(1~4):1; before sandblasting, first pour the three raw materials into the iron bucket at the same time to facilitate the mixing of raw materials , and then pour the mixed sand in the iron bucket into the sand tank for sandblasting, the blasting air source pressure is 0.5‑0.9MPa; the present invention optimizes the composition of sand grains, increases the air source pressure, and greatly shortens the old coating Removal time, compared with single ceramic sandblasting to remove old coatings, the time is reduced by 60-75%, while reducing production costs, realizing the economical and efficient removal of old coatings, suitable for various metals, alloys, and cermet coatings layer removal.

Owner:XIAN THERMAL POWER RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com