Ozone oxidation ammonia gas catalyst, preparation method and application thereof

An ozone oxidation and catalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, molecular sieve catalysts, etc., can solve the problem of low ammonia removal rate, high maintenance cost, light utilization problems such as low rate, to achieve the effect of improving dispersibility and moisture resistance, improving service life, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

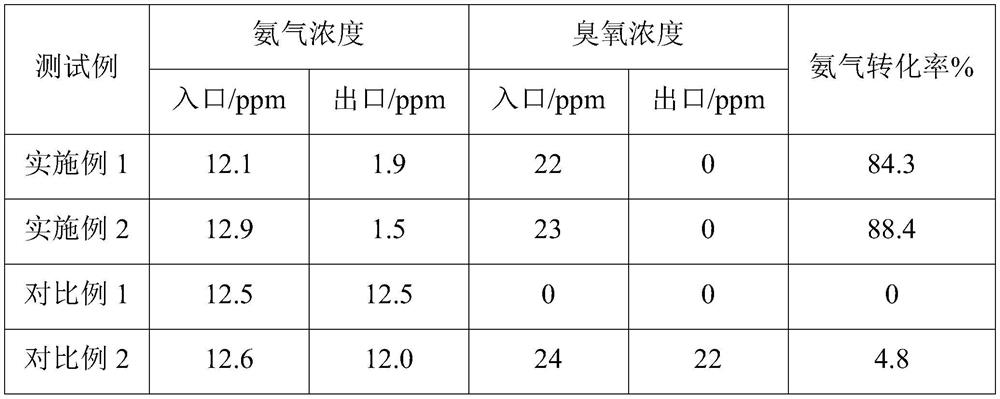

Examples

Embodiment 1

[0033] After ball milling 5g of titanium dioxide and 88g of molecular sieve for 1h, roast at 450°C for 5h to form titanium dioxide / molecular sieve; add 6.43g of copper nitrate trihydrate, 6.17g of manganese nitrate, and 1.51g of ferric nitrate into 310ml of deionized water, stir Dissolve to obtain a metal salt solution, then add titanium dioxide / molecular sieve, continue to stir, dropwise add an ammonium carbonate solution with a mass fraction of 1%, until the pH value of the metal salt solution reaches 7.5, stop dripping the ammonium carbonate solution, and continue stirring for 4h, Let it stand at room temperature for 24 hours, wash the obtained precipitate with deionized water, filter, dry at 90°C for 4 hours, add 2g of carboxymethylcellulose as a binder, knead and extrude it, and then roast at 300°C for 3 hours to obtain ozone oxidation Ammonia catalyst.

[0034] According to the amount of the metal ion of the added metal salt, it can be known that the ozone oxidation ammo...

Embodiment 2

[0036] Mix 12g of titanium dioxide and 66g of molecular sieve by ball milling for 2h, then roast at 550°C for 5h to form titanium dioxide / molecular sieve; add 17.15g of copper nitrate trihydrate, 20.57g of manganese nitrate, and 6.04g of ferric nitrate into 970ml of deionized water, stir Dissolve to obtain a metal salt solution, then add titanium dioxide / molecular sieve, continue to stir, dropwise add a sodium bicarbonate solution with a mass fraction of 5%, until the pH value of the metal salt solution reaches 8.3, stop adding, continue to stir for 6h, at room temperature Let it stand for 24 hours, wash the obtained precipitate with deionized water, filter, dry at 120°C for 6 hours, add 2g of carboxymethylcellulose as a binder, knead and press it into tablets, then break it into 2mm ~ 3mm particles, and then dry it at 450 Calcined at ℃ for 6h to obtain an ammonia catalyst for ozone oxidation.

[0037] According to the amount of the metal ion of the added metal salt, it can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com