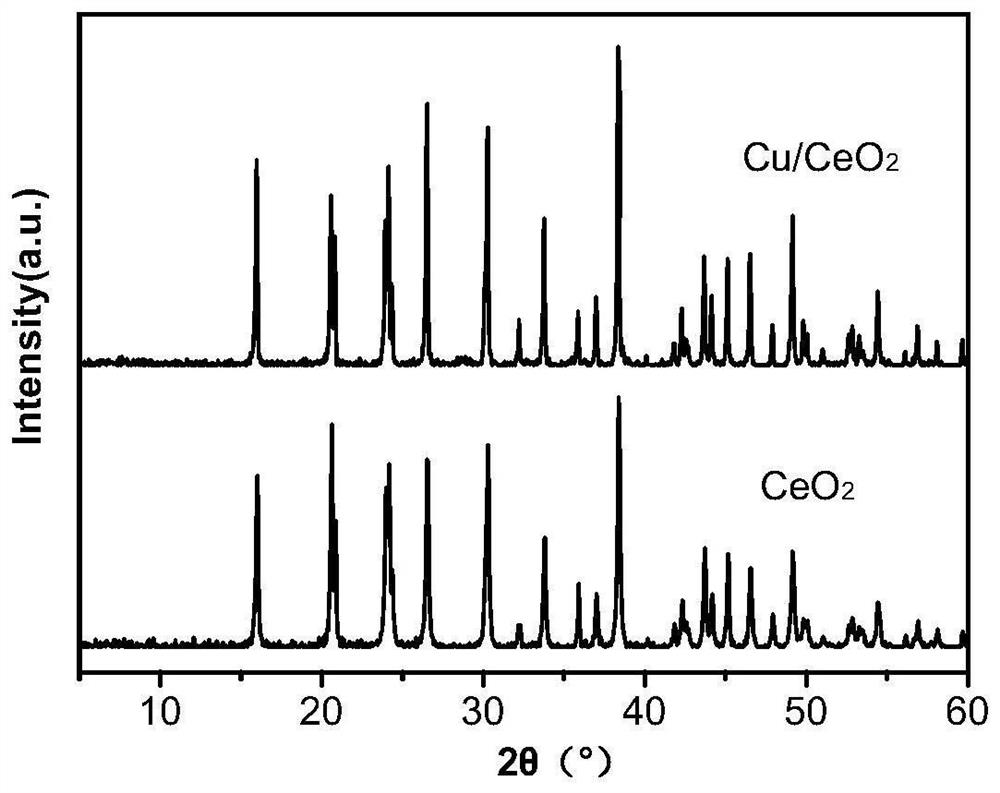

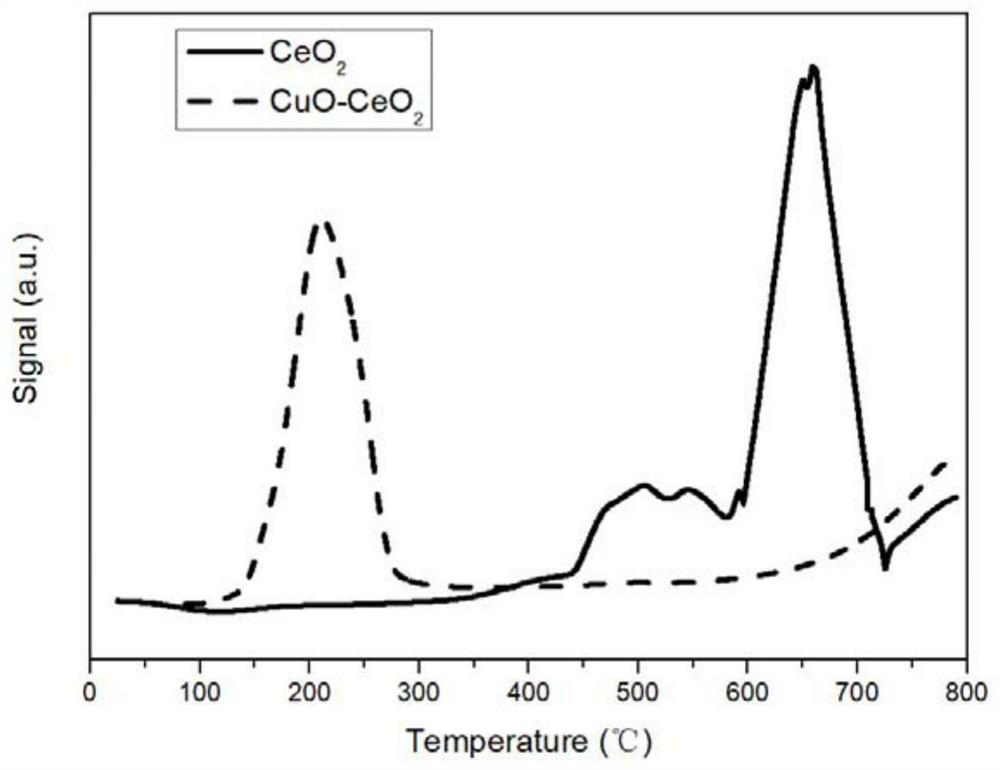

Preparation method of CuO-CeO2 supported catalyst and application of CuO-CeO2 supported catalyst in anaerobic elimination of NOx and CO in tail gas

A supported catalyst and precipitant technology, applied in catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of complex catalyst composition and achieve good selectivity , the effect of high low temperature activity and large reaction window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037](1) Form a mixed solution with cerium nitrate and sodium carbonate according to the quality of 1g and 3g, then place the mixed solution in a reaction kettle and transfer it into an oven, set the temperature range of the oven to 120°C, keep it for 10h, and wait for the temperature to drop to At room temperature, the resulting white suspension was filtered, washed, and dried to obtain a white cerium oxide powder (carrier).

[0038] (2) 1gCeO obtained in (1) 2 The white powder was dispersed in the aqueous solution, and then 0.1 g of copper nitrate was added thereto. The precipitating agent is the same as (1), put the mixed solution in a 70°C water bath, keep stirring at a constant temperature for 2 hours, then filter the mixed solution after the water bath, wash, and dry to obtain 10% CuO-90% CeO 2 .

[0039] (3) Take the material from (2) and place it in a muffle furnace for calcination for 2 hours at a calcination temperature of 200°C. Finally get 10%CuO-90%CeO 2 , re...

Embodiment 2

[0043] (1) Form a mixed solution with cerium nitrate and sodium bicarbonate according to the quality of 1g and 3g, then place the mixed solution in a reaction kettle and transfer it into an oven, set the temperature range of the oven to 120°C, keep it for 10h, and wait for the temperature to reach room temperature, the resulting white suspension was filtered, washed, and dried to obtain a white cerium oxide powder (carrier).

[0044] (2) 1gCeO obtained in (1) 2 The white powder was dispersed in the aqueous solution, and 1 g of copper nitrate was added thereto. The precipitating agent is the same as (1), put the mixed solution in a 70°C water bath, keep stirring at a constant temperature for 2 hours, then filter the mixed solution after the water bath, wash, and dry to obtain 50%CuO-50%CeO 2 .

[0045] The material in (2) was calcined in a muffle furnace for 2 hours at a calcination temperature of 250°C. Finally get 50%CuO-50%CeO 2 , Record as CuCe-2.

Embodiment 3

[0047] Cerium nitrate and potassium carbonate are mixed according to the quality of 1g and 3g, and then the mixed solution is placed in the reaction kettle and transferred into the oven. The temperature range of the oven is set at 120°C and kept for 10h. The resulting white suspension was filtered, washed and dried to obtain a white cerium oxide powder (support).

[0048] 1gCeO obtained by (1) 2 The white powder was dispersed in the aqueous solution, and then 4 g of copper nitrate was added thereto. The precipitating agent is the same as (1), put the mixed solution in a 70°C water bath, keep stirring at a constant temperature for 2 hours, then filter the mixed solution after the water bath, wash, and dry to obtain 80%CuO-20%CeO 2 .

[0049] The material in (2) was calcined in a muffle furnace for 2 hours at a calcination temperature of 300°C. Finally get 80%CuO-20%CeO 2 , Record as CuCe-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com