Auxiliary robot for cable construction

A robot and cable technology, applied in the direction of line/collector parts, circuits, electrical components, etc., can solve the problems of thick outer sheath, time-consuming and laborious, etc., and achieve the effect of convenient cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

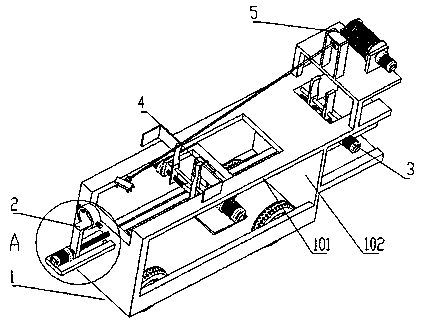

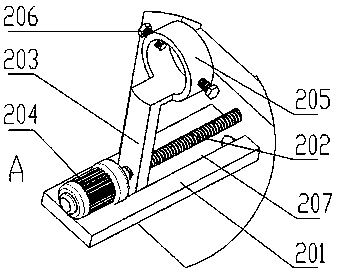

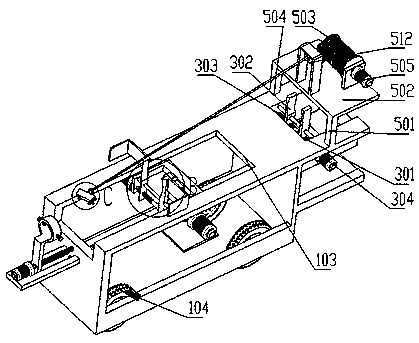

[0032] see Figure 1-Figure 9 , an auxiliary robot for cable construction, comprising a frame 1, the frame 1 comprising a top plate 101 and vertical plates 102 arranged at both ends of the top plate 101, a screw 6 is arranged to rotate between the two vertical plates 102, and the top plate 101 is connected with the screw rod The position corresponding to one 6 is provided with a rectangular opening 103, and the screw rod one 6 is provided with a moving plate 602 through threaded connection, and the moving plate 1 602 passes through the stop bar 601 arranged between the two vertical plates 102, and the stop bar 601 is located above the screw rod one 6, the moving plate one 602 is provided with a cutting mechanism 4, the outer side of any vertical board 102 is provided with a steel armor tightening mechanism 2, and the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com