Method for removing endotoxin in bacterial cellulose

A bacterial cellulose and endotoxin technology, which is applied in the post-treatment of cellulose pulp, fiber raw material treatment, pulp fat/resin/pitch/wax removal, etc., can solve the problems of poor removal effect and speed up the purification process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

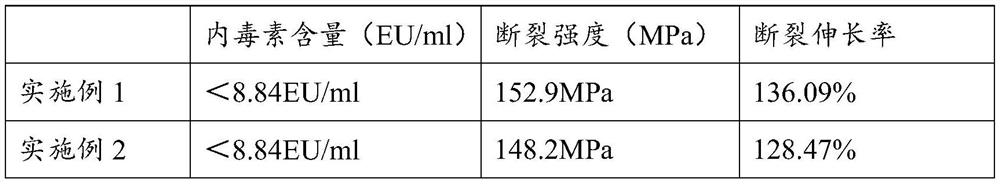

Embodiment 1

[0034] (1) Soak the sliced bacterial cellulose in 2% sodium hydroxide solution by mass fraction, replace the sodium hydroxide solution four times and soak for four hours each time; kill the bacteria so that the endotoxin is completely released and also accelerate the bacterial cellulose the process of purification;

[0035] (2) soak bacterial cellulose in 10% ethanol by volume fraction, and utilize 10% ethanol to dissolve the endotoxin in the porous structure;

[0036] (3) Add mass fraction 2% sodium hydroxide solution and positively charged polysulfone resin polymer to the bacterial cellulose processed in the second step, the polysulfone resin polymer has good hydrophilicity and can effectively adsorb and filter In addition to endotoxin in liquid and bacterial cellulose, and 2% sodium hydroxide solution will completely kill the endotoxin adsorbed;

[0037] (4) Soak the treated bacterial cellulose with water for injection to make it reach a pH range of 7±1.

[0038] (5) Sa...

Embodiment 2

[0040] (1) Soak the pieced bacterial cellulose in 3% sodium hydroxide solution by mass fraction, replace the sodium hydroxide solution four times and soak for four hours each time; kill the bacteria so that the endotoxin is completely released and also accelerate the bacterial cellulose the process of purification;

[0041] (2) soak bacterial cellulose in 15% ethanol by volume fraction, and utilize 15% ethanol to dissolve the endotoxin in the porous structure;

[0042] (3) The bacterial cellulose processed in the second step is added to a mass fraction of 3% sodium hydroxide solution and a positively charged polysulfone resin polymer. The polysulfone resin polymer has good hydrophilicity and can effectively adsorb and filter In addition to endotoxin in liquid and bacterial cellulose, and 3% sodium hydroxide solution will completely kill the endotoxin adsorbed;

[0043] (4) Soak the treated bacterial cellulose with water for injection to make it reach a pH range of 7 ± 1;

[00...

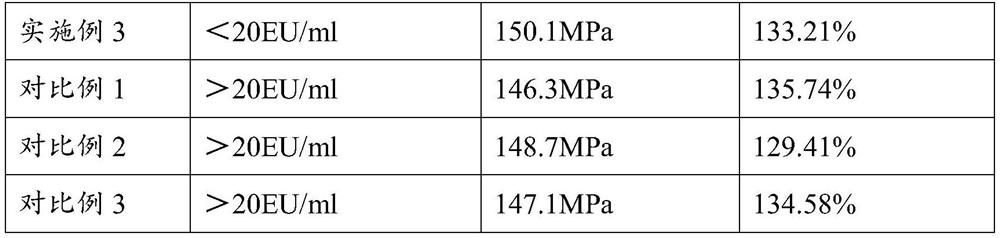

Embodiment 3

[0046] (1) Soak the sliced bacterial cellulose in 1% sodium hydroxide solution by mass fraction, replace the sodium hydroxide solution four times, soak for four hours each time, kill the bacteria so that the endotoxin is completely released and also accelerate the bacterial fiber The process of element purification;

[0047] (2) Soak the bacterial cellulose in 5% ethanol by volume fraction, and use 5% ethanol to dissolve the endotoxin in the porous structure;

[0048] (3) Add mass fraction 1% sodium hydroxide solution and positively charged polysulfone resin polymer to the bacterial cellulose processed in step (2), the polysulfone resin polymer has good hydrophilicity and can effectively adsorb Filter out endotoxins in liquid and bacterial cellulose, and 1% sodium hydroxide solution will completely kill the adsorbed endotoxins;

[0049] (4) Soak the treated bacterial cellulose with water for injection to make it reach a pH range of 7±1;

[0050] (5) Samples were randomly s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com