Method for removal of vegetable oil precipitate after pressing

A vegetable oil and removal technology, applied in the direction of fat oil/fat refining, fat production, etc., can solve the problems of increasing trichloropropanol ester in fat, destroying natural active components of oil, and changing the taste of vegetable oil, which is time-consuming. The effect of short, low cost and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for removing precipitation of linseed oil after machine pressing, the method for removing precipitation of linseed oil after machine pressing comprises the steps:

[0023] ①The machine-pressed linseed oil is coarsely filtered through a plate frame, the pressure of the plate frame is <0.4MPa, and liquid I is obtained;

[0024] ② Adding Span 60 to Liquid I for microwave radiation treatment, the amount of Span 60 added is 0.35% of the weight of Liquid I, the microwave radiation power is 300W, and microwave radiation is performed at 60°C for 20 minutes to obtain Liquid II;

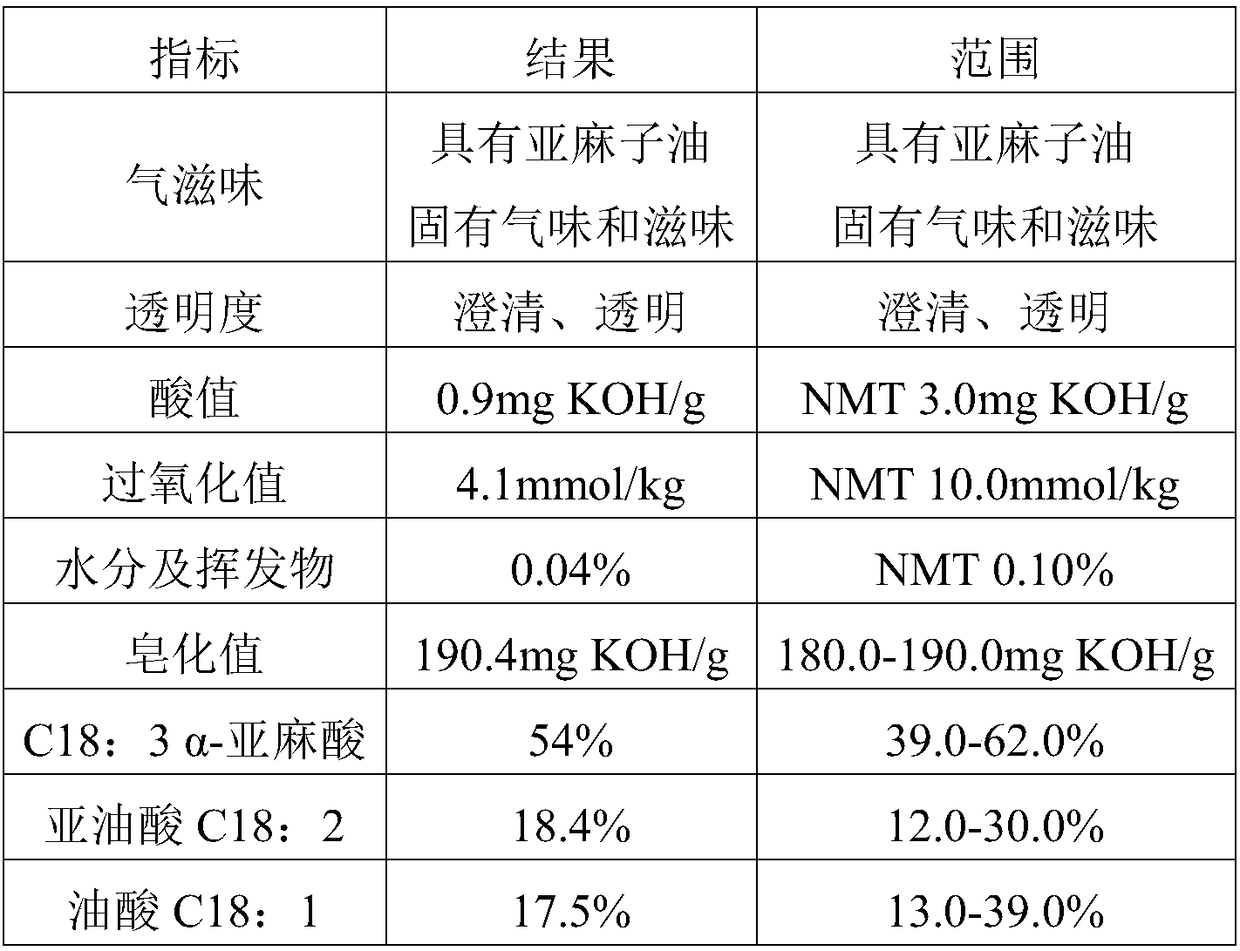

[0025] ③ Cool the liquid II at 4°C for 10 hours, filter, remove the precipitate, obtain the linseed oil after removing the precipitate, measure its related indicators, and the results are shown in Table 1;

[0026] ④ Place the linseed oil at 4°C for 3 months after the precipitation has been removed, and measure its turbidity and precipitation. The results are shown in Table 2.

[0027] The lin...

Embodiment 2

[0032] A method for removing the precipitation of white melon seed oil after machine pressing, the method for removing the precipitation of white melon seed oil after machine pressing comprises the following steps:

[0033] ① The pressed white melon seed oil is subjected to coarse filtration through a plate frame, the pressure of the plate frame is <0.4MPa, and liquid I is obtained;

[0034] ② Add sucrose fatty acid ester to liquid I for microwave radiation treatment, the added amount of said sucrose fatty acid ester is 0.4% of the weight of liquid I, the power of microwave radiation is 320W, microwave radiation at 65°C for 15 minutes, and liquid II is obtained;

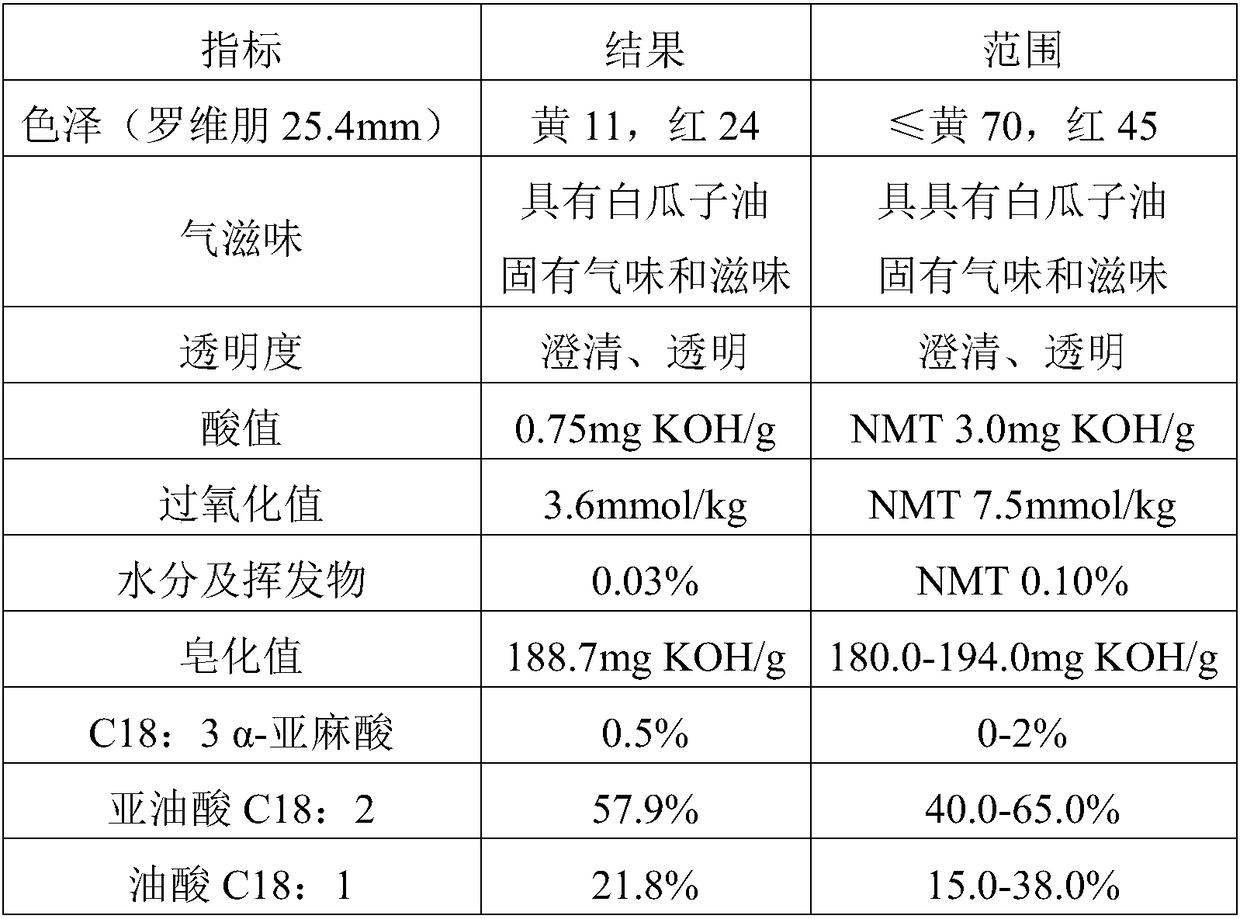

[0035] ③ Cool the liquid II at 4°C for 10 hours, filter, remove the precipitate, and obtain the white melon seed oil after removing the precipitate, measure its related indicators, and the results are shown in Table 3;

[0036] ④ Place the white melon seed oil at 4°C for 3 months after the precipitation has been remo...

Embodiment 3

[0042] A method for removing the precipitation of sesame oil after machine pressing, the method for removing the precipitation of sesame oil after machine pressing comprises the steps:

[0043] ①The sesame oil after machine pressing is coarsely filtered through the plate frame, the pressure of the plate frame is <0.4MPa, and the liquid I is obtained;

[0044] ②Add sucrose laurate to Liquid I for microwave radiation treatment, the amount of sucrose laurate added is 0.5% of the weight of Liquid I, the power of microwave radiation is 350W, microwave radiation at 60°C for 20 minutes, and Liquid II is obtained;

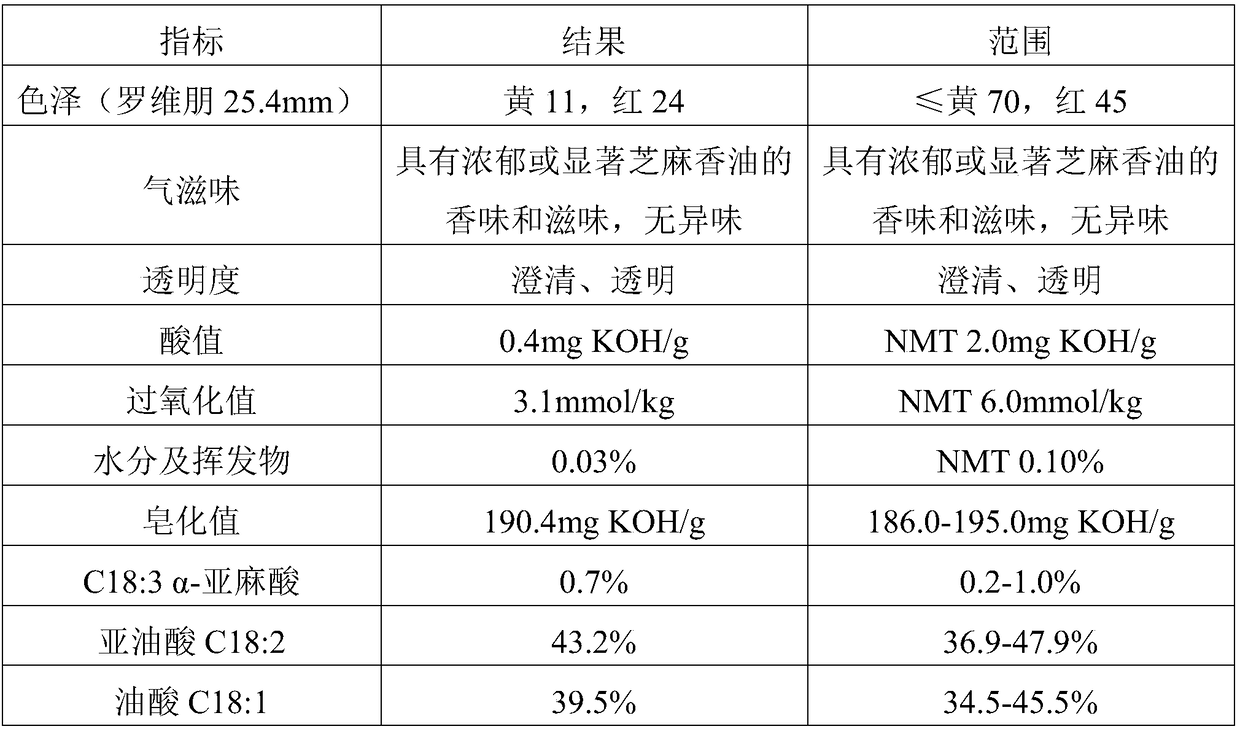

[0045] ③ Cool the liquid II at 4°C for 10 hours, filter, remove the precipitate, and obtain the sesame oil after removing the precipitate, measure its related indicators, and the results are shown in Table 5;

[0046] ④ Place the sesame oil at 4°C for 3 months after removing the precipitate, and measure its turbidity and precipitation. The results are shown in Table 6.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com