A kind of attapulgite clay composite catalyst for removing formaldehyde and its preparation method and application

A technology of attapulgite clay and composite catalyst, which is applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of low adsorption conversion rate and high catalytic activity , insufficient strength and other problems, to achieve the effect of large cohesion, large specific surface area, and increased adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

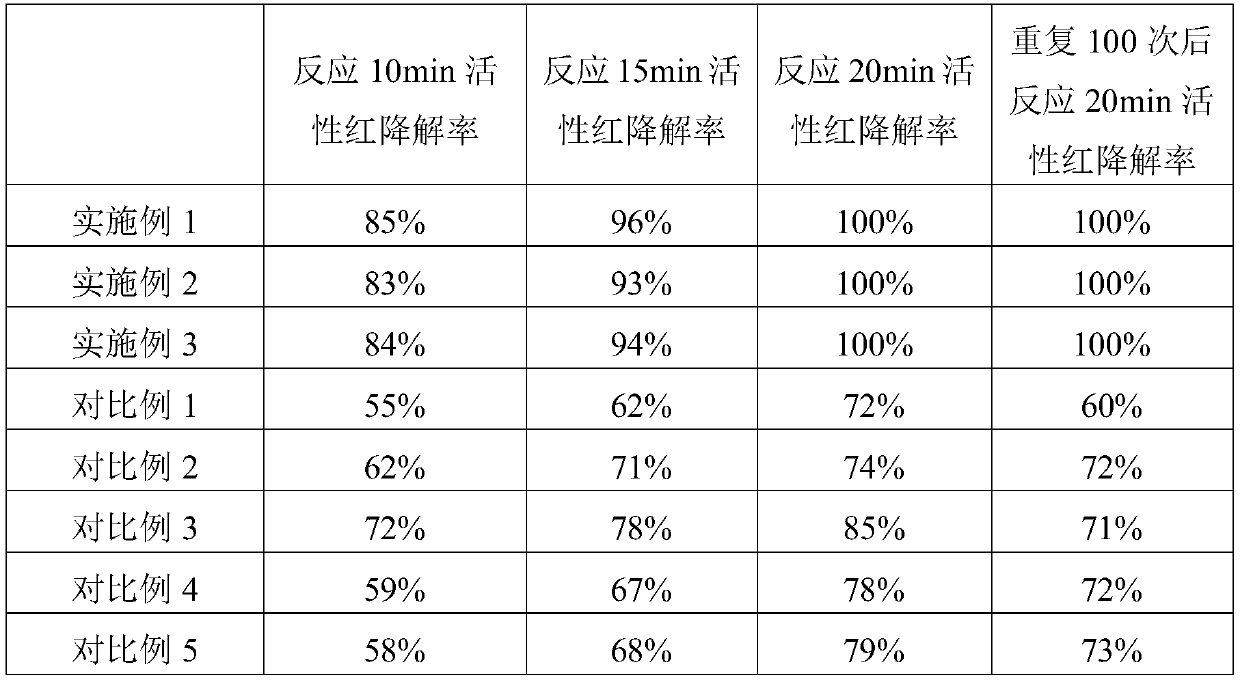

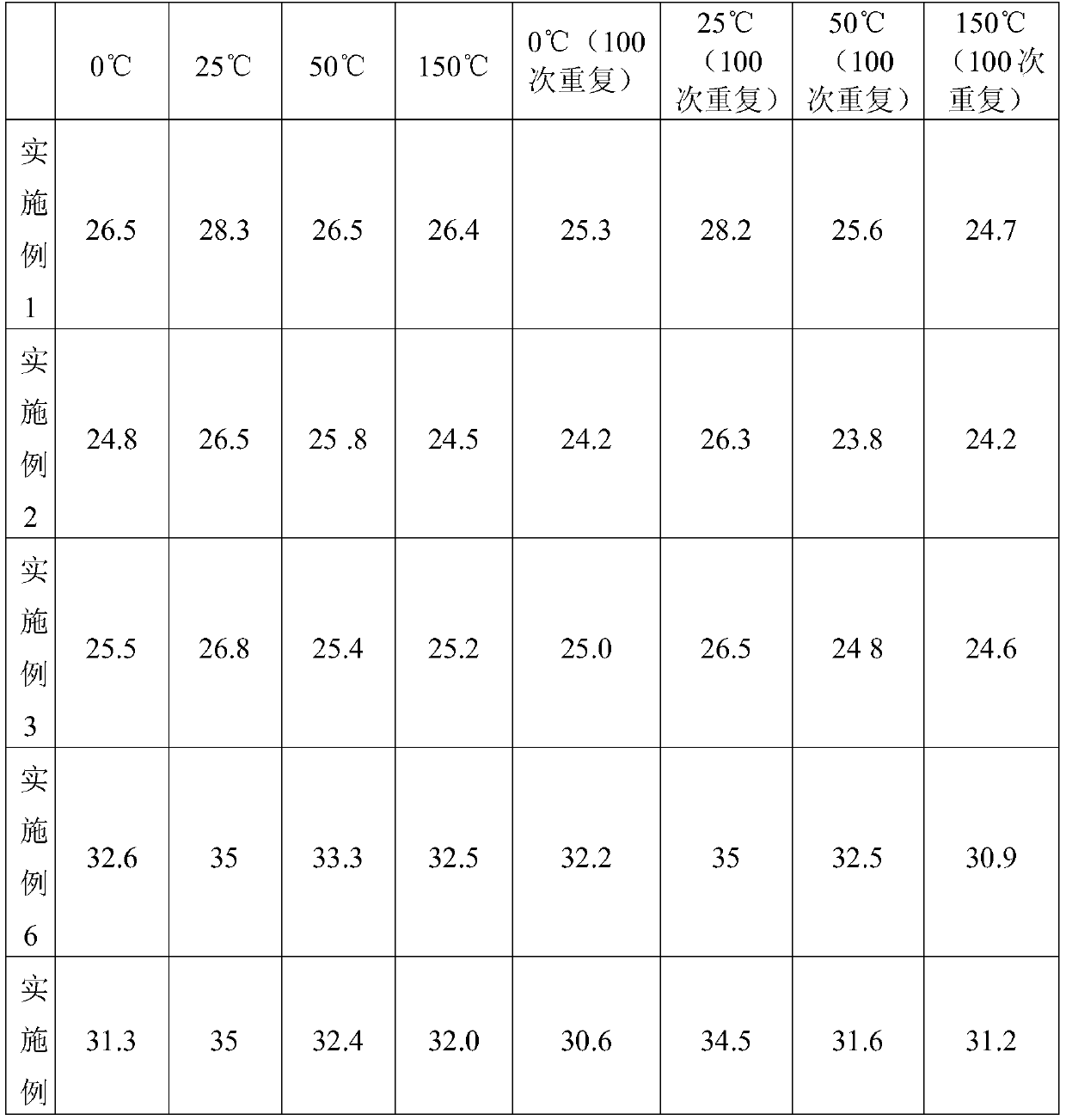

Embodiment 1

[0034] raw material:

[0035] 38 parts of attapulgite clay, 30 parts of titanium dioxide, 12 parts of polybutyl acrylate, 5 parts of methyl cellulose, 8 parts of fatty acid diethanolamide, 8 parts of phthalic acid; the amount of platinum chloride solution is based on the mass of precious metal platinum It accounts for 0.0008% of the mass of the attapulgite clay, and the amount of sodium carbonate solution added accounts for 0.015% of the mass of the attapulgite clay based on the mass of the active metal sodium element. Among them, the number average molecular weight of polybutyl acrylate is 10000.

[0036] Preparation:

[0037] (1) Weigh each raw material in proportion, dissolve polybutylacrylate in absolute ethanol, stir and dissolve at 40°C, add fatty acid diethanolamide, then slowly add methyl cellulose to react for 18 hours, dry and concentrate to obtain the reactant A, then add the attapulgite clay and the reactant A into absolute ethanol, stir and mix, and ultrasonicat...

Embodiment 2

[0042] raw material:

[0043] 30 parts of attapulgite clay, 25 parts of cerium oxide, 8 parts of polybutyl acrylate, 3 parts of methyl cellulose, 5 parts of fatty acid diethanolamide, 5 parts of phthalic acid; The mass of gold element accounts for 0.0005% of the mass of the attapulgite clay, and the addition of potassium chloride solution accounts for 0.01% of the mass of the attapulgite clay based on the mass of active metal potassium. Among them, the number average molecular weight of polybutyl acrylate is 8000.

[0044] Preparation:

[0045] (1) Weigh each raw material in proportion, dissolve polybutylacrylate in absolute ethanol, stir and dissolve at 35°C, add fatty acid diethanolamide, then slowly add methyl cellulose to react for 15 hours, dry and concentrate to obtain reactant A , and then add attapulgite clay and reactant A into absolute ethanol, stir and mix, and ultrasonicate for 20 minutes to obtain mixture A;

[0046] (2) Add metal oxide powder and phthalic acid...

Embodiment 3

[0050] raw material:

[0051] 45 parts of attapulgite clay, 35 parts of aluminum oxide, 15 parts of polybutyl acrylate, 8 parts of methyl cellulose, 10 parts of fatty acid diethanolamide, 10 parts of phthalic acid; The mass of the element accounts for 0.001% of the mass of the attapulgite clay, and the added amount of the sodium carbonate solution accounts for 0.02% of the mass of the attapulgite clay based on the mass of the active metal sodium element. Among them, the number average molecular weight of polybutyl acrylate is 10000.

[0052] Preparation:

[0053] (1) Weigh each raw material in proportion, dissolve polybutylacrylate in absolute ethanol, stir and dissolve at 40°C, add fatty acid diethanolamide, then slowly add methyl cellulose to react for 20 hours, dry and concentrate to obtain reactant A , and then add attapulgite clay and reactant A into absolute ethanol, stir and mix, and ultrasonicate for 30 minutes to obtain mixture A;

[0054] (2) Add metal oxide powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com