Iron-based catalyst for strengthening ozone oxidation of organic pollutants and preparation method thereof

A technology for iron-based catalysts and organic pollutants, which is applied in the direction of metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, water pollutants, etc., to achieve improved utilization, simple methods, and improved ratio The effect of surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The synthesis of embodiment 1 iron-based catalyst

[0036] Soak 200g of zeolite in a ferrous salt solution with a concentration of 1.0 mol / L, and add 0.5 mol / L of alkaline potassium ferrate with the same volume as the ferrous salt while stirring continuously The solution and 0.2 mol / L hydrogen peroxide solution were stirred at room temperature for 30 minutes, and then the zeolite was separated, dried in an oven at 80°C for 12 hours, and cooled to obtain the iron-based catalyst 1.

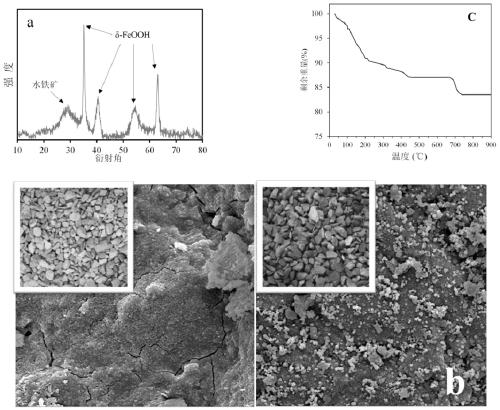

[0037] A series of characterization tests were carried out on the above iron-based catalysts, including X-ray diffraction (XRD), scanning electron microscopy (SEM) and thermogravimetric analysis (TGA). From the results of XRD, it can be seen that compared with the amorphous characteristics of natural zeolite, the material after the above treatment has the typical diffraction peak characteristics of δ-FeOOH and ferrihydrite; it can be seen from the SEM image that after Compared with the surfa...

Embodiment 2

[0038] The synthesis of embodiment 2 iron-based catalysts

[0039] Soak 200g of zeolite in a ferrous salt solution with a concentration of 0.5 mol / L, and add 0.3 mol / L of alkaline potassium ferrate with the same volume as the ferrous salt while stirring continuously The solution and 0.2 mol / L hydrogen peroxide solution were stirred at room temperature for 30 minutes, and then the zeolite was separated, dried in an oven at 80°C for 12 hours, and cooled to obtain the iron-based catalyst 2.

Embodiment 3

[0041]Soak 200g of zeolite in a ferrous salt solution with a concentration of 0.75mol / L, and add half of the same volume of the ferric salt solution with 0.5mol / L alkaline ferrate under constant stirring. Potassium solution and 0.2 mol / L hydrogen peroxide solution were stirred at room temperature for 30 minutes, and then the zeolite was separated, dried in an oven at 80° C. for 12 hours, and cooled to obtain iron-based catalyst 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com