Method for removing brominated flame retardant in water body

A brominated flame retardant, water technology, applied in chemical instruments and methods, water pollutants, water/sewage treatment and other directions, can solve the problems of reducing COD value of sewage, complicated steps, high cost, and achieve good degradation effect, environmental protection Friendly, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A photocatalytic oxidation method for efficiently removing brominated flame retardants in water, comprising the following steps:

[0024] (1) Prepare 100 mL of tetrabromobisphenol A solution with an initial concentration of 2 mg / L in a beaker;

[0025] (2) Add a certain amount of sodium hypochlorite so that the available chlorine concentration is 1mmol / L;

[0026] (3) open the magnetic stirring device of reaction vessel and start magnetic stirring;

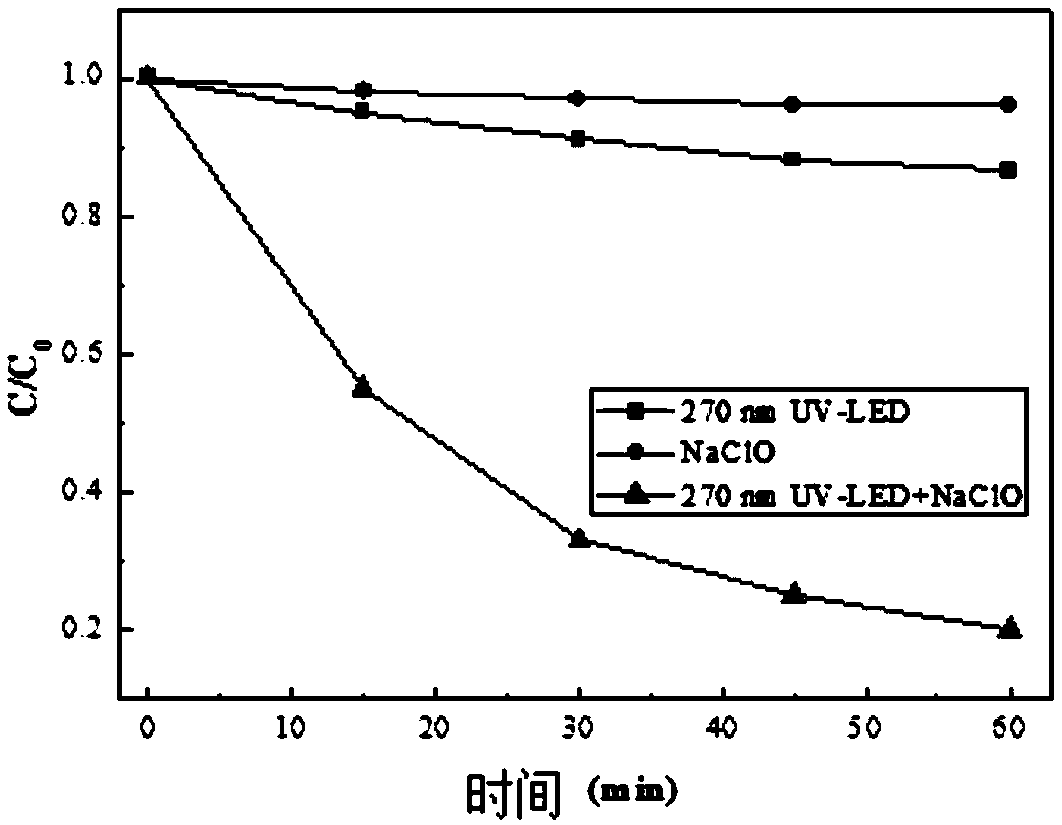

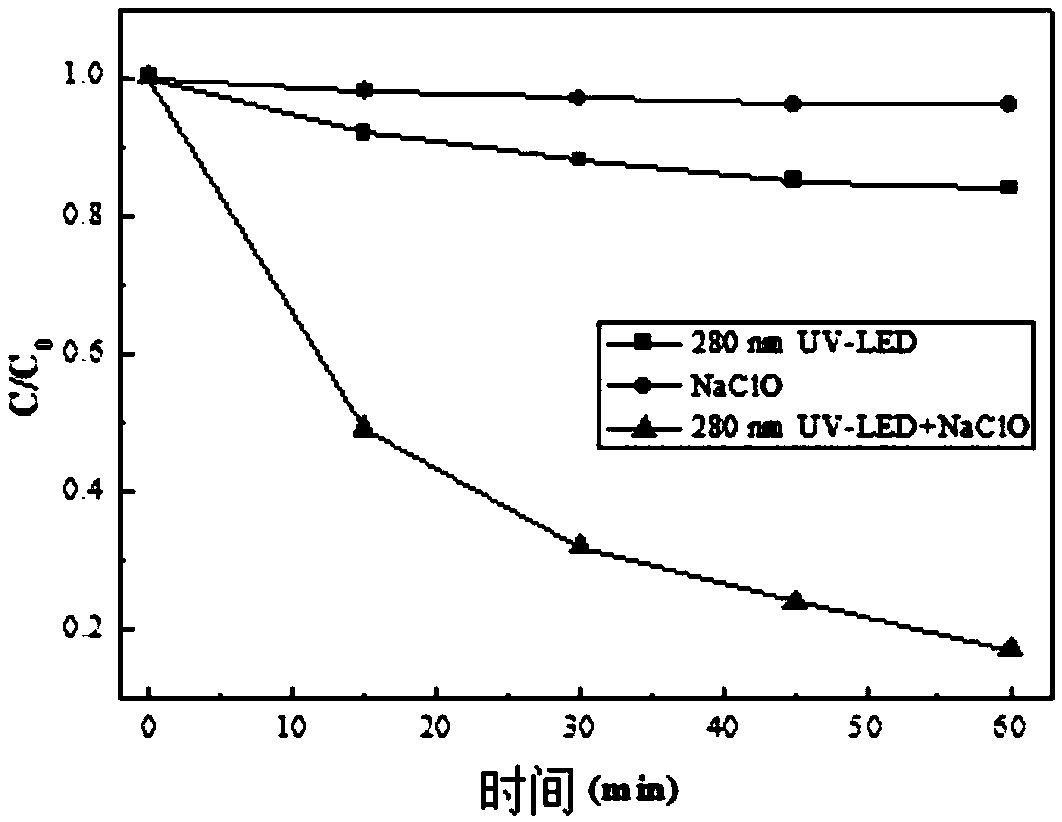

[0027] (4) Turn on the 280nm LED ultraviolet lamp to irradiate the mixed solution;

[0028] (5) Sampling in specific time interval, the concentration of tetrabromobisphenol A in the test sample, test result is as follows figure 2 shown. It can be seen that through 60min, the concentration of tetrabromobisphenol A is reduced from 2mg / L to 0.34mg / L, and the removal rate can reach 83%.

Embodiment 2

[0030] A photocatalytic oxidation method for efficiently removing brominated flame retardants in water, comprising the following steps:

[0031] (1) Prepare 100 mL of tribromophenol solution with an initial concentration of 2 mg / L in a beaker;

[0032] (2) Add a certain amount of sodium hypochlorite so that the available chlorine concentration is 3mmol / L;

[0033] (3) open the magnetic stirring device of reaction vessel and start magnetic stirring;

[0034] (4) Turn on the 280nm LED ultraviolet lamp to irradiate the mixed solution;

[0035] (5) Sampling in specific time interval, the concentration of tribromophenol in the test sample, test result is as follows figure 1 shown. It can be seen that through 60min, the concentration of tetrabromobisphenol A was reduced from 2mg / L to 0.41mg / L, and the removal rate was 80%.

Embodiment 3

[0037] A photocatalytic oxidation method for efficiently removing brominated flame retardants in water, comprising the following steps:

[0038] (1) Prepare 100 mL of bisphenol A solution with an initial concentration of 2 mg / L in a beaker;

[0039] (2) Add a certain amount of sodium hypochlorite so that its available chlorine concentration is 5mmol / L;

[0040] (3) open the magnetic stirring device of reaction vessel and start magnetic stirring;

[0041] (4) Turn on the 280nm LED ultraviolet lamp to irradiate the mixed solution;

[0042] (5) Samples are taken at specific time intervals to test the concentration of bisphenol A in the samples.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com