Adsorbing material for removing organic sulfur in coke oven gas and application of adsorbing material

An adsorption material, coke oven gas technology, applied in inorganic chemistry, other chemical processes, combustible gas purification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

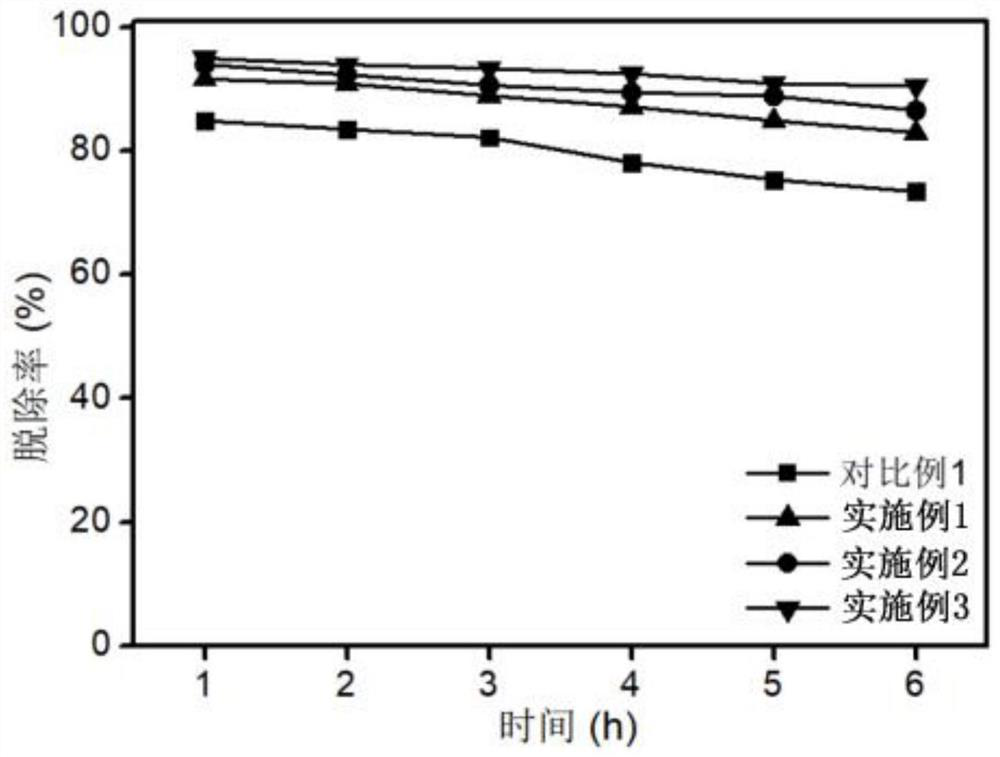

Embodiment 1

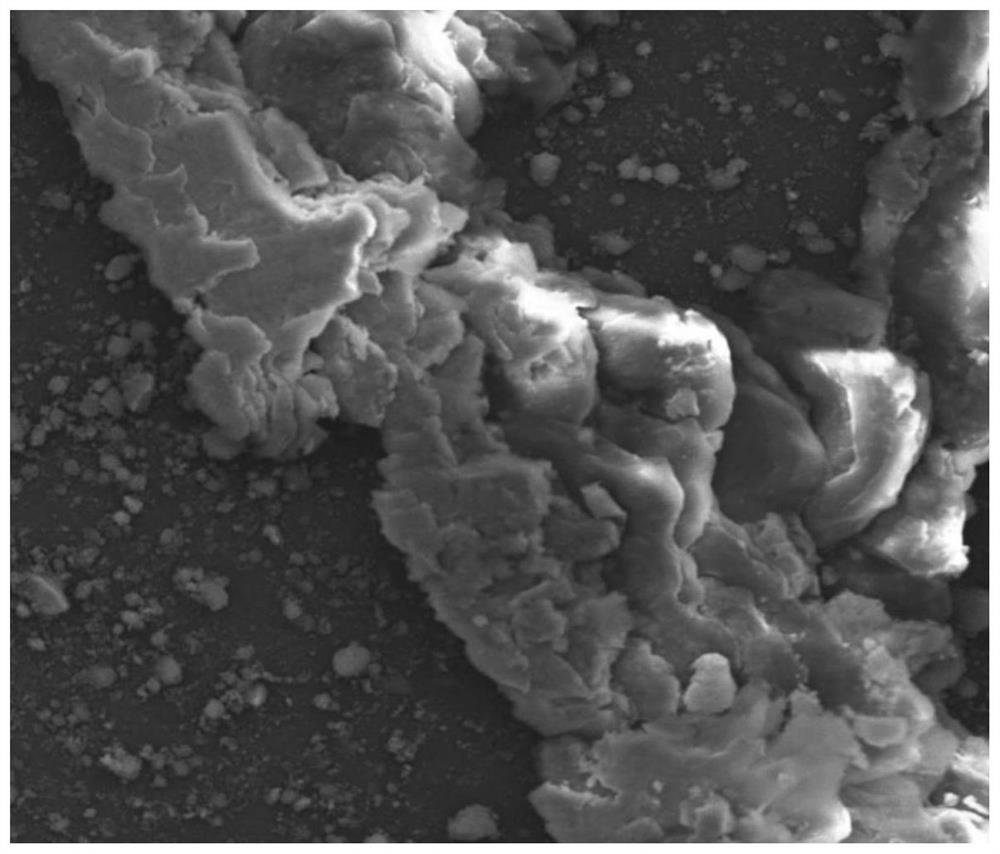

[0031] An adsorption material for removing organic sulfur in coke oven gas, the preparation steps of which are as follows:

[0032] 1) Wash granular activated carbon (blue carbon, particle size 0.5-1.0 cm) with water until the pH becomes neutral, and dry at 110°C for 4 hours to obtain pretreated activated carbon for later use;

[0033]2) Weigh N-methylimidazole, ethyl bromide and anhydrous sodium acetate respectively according to the molar ratio of 1:1.1:1.2. Then add weighed N-methylimidazole and anhydrous sodium acetate into the round bottom flask, then add acetone solvent and activated carbon (the mass ratio of acetone solvent and activated carbon is 2:1), and then use a constant pressure funnel to weigh Bromoethane was slowly added dropwise into a round-bottomed flask for a stirring reaction (reaction temperature 20°C, stirring for 8 h), so that N-methylimidazole, bromoethane and anhydrous sodium acetate reacted in situ on activated carbon to form 1 -Ethyl-3-methylimidazo...

Embodiment 2

[0036] An adsorption material for removing organic sulfur in coke oven gas, the preparation steps of which are as follows:

[0037] 1) Wash granular activated carbon (blue carbon, particle size 0.5-1.0 cm) with water until the pH becomes neutral, and dry at 110°C for 6 hours to obtain pretreated activated carbon for later use;

[0038] 2) Weigh N-methylimidazole, ethyl bromide and anhydrous sodium acetate respectively according to the molar ratio of 1:1.1:1.2. Then add weighed N-methylimidazole and anhydrous sodium acetate into the round bottom flask, then add acetone solvent and activated carbon (the mass ratio of acetone solvent and activated carbon is 2:1), and then use a constant pressure funnel to weigh Bromoethane was slowly added dropwise into a round bottom flask, and the reaction was stirred (reaction temperature 20°C, stirred for 10 h), so that N-methylimidazole, bromoethane and anhydrous sodium acetate reacted in situ on activated carbon to form 1 -Ethyl-3-methylim...

Embodiment 3

[0041] An adsorption material for removing organic sulfur in coke oven gas, the preparation steps of which are as follows:

[0042] 1) Wash granular activated carbon (blue carbon, particle size 0.5-1.0 cm) with water until the pH becomes neutral, and dry at 110°C for 8 hours to obtain pretreated activated carbon, which is ready for use;

[0043] 2) Weigh N-methylimidazole, ethyl bromide and anhydrous sodium acetate respectively according to the molar ratio of 1:1.1:1.2. Then add weighed N-methylimidazole and anhydrous sodium acetate into the round bottom flask, then add acetone solvent and activated carbon (the mass ratio of acetone solvent and activated carbon is 2:1), and then use a constant pressure funnel to weigh Bromoethane was slowly added dropwise into a round-bottomed flask for a stirring reaction (reaction temperature 20°C, stirring for 12 h), so that N-methylimidazole, bromoethane and anhydrous sodium acetate reacted in situ on activated carbon to form 1 -Ethyl-3-m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

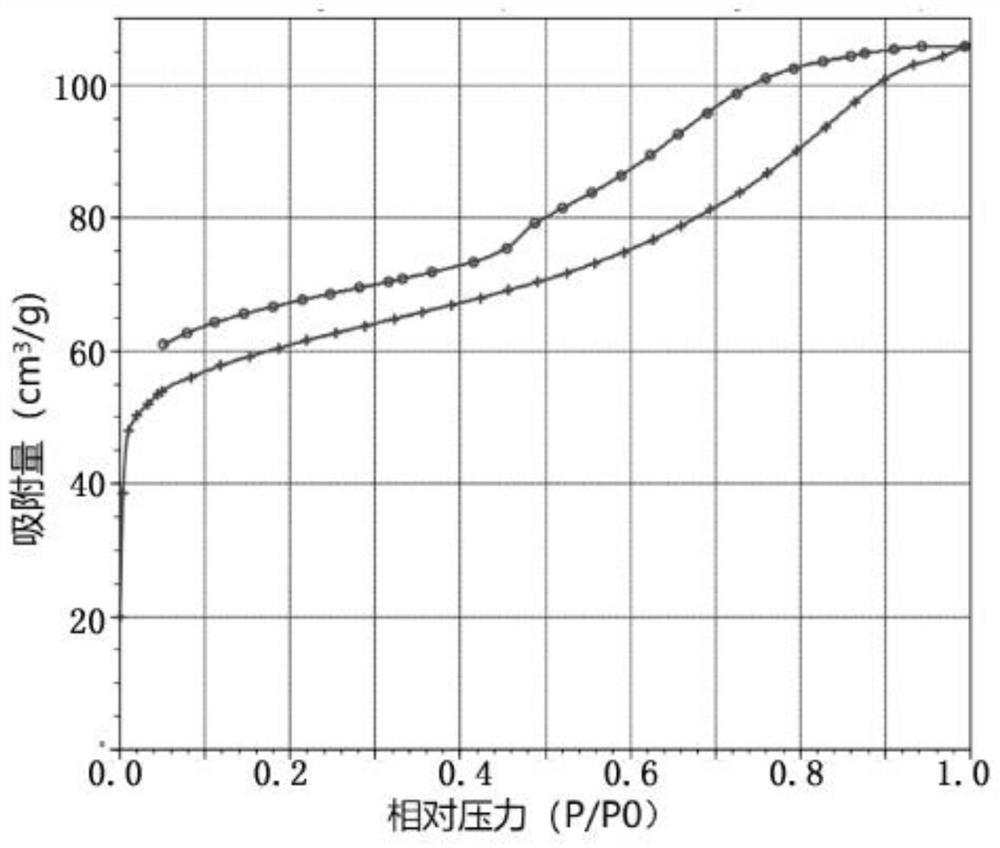

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com