A phosphorus removal agent containing inorganic minerals and its application method

A technology of inorganic minerals and phosphorus removal agent, applied in the field of water treatment research, can solve the problem of low phosphorus removal rate, and achieve the effect of good phosphorus removal effect, simple preparation and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Taking 2000mg of inorganic mineral phosphorus removal agent as an example, it is made by fully mixing 1400mg of polyaluminum chloride (PAC), 400mg of bentonite, and 200mg of ferrous sulfate, of which polyaluminum chloride (PAC) accounts for 70% of the total mass , bentonite accounted for 20%, ferrous sulfate accounted for 10%.

[0031] The dephosphorization agent is dissolved in water according to the mass concentration of 2%, and mixed before each use.

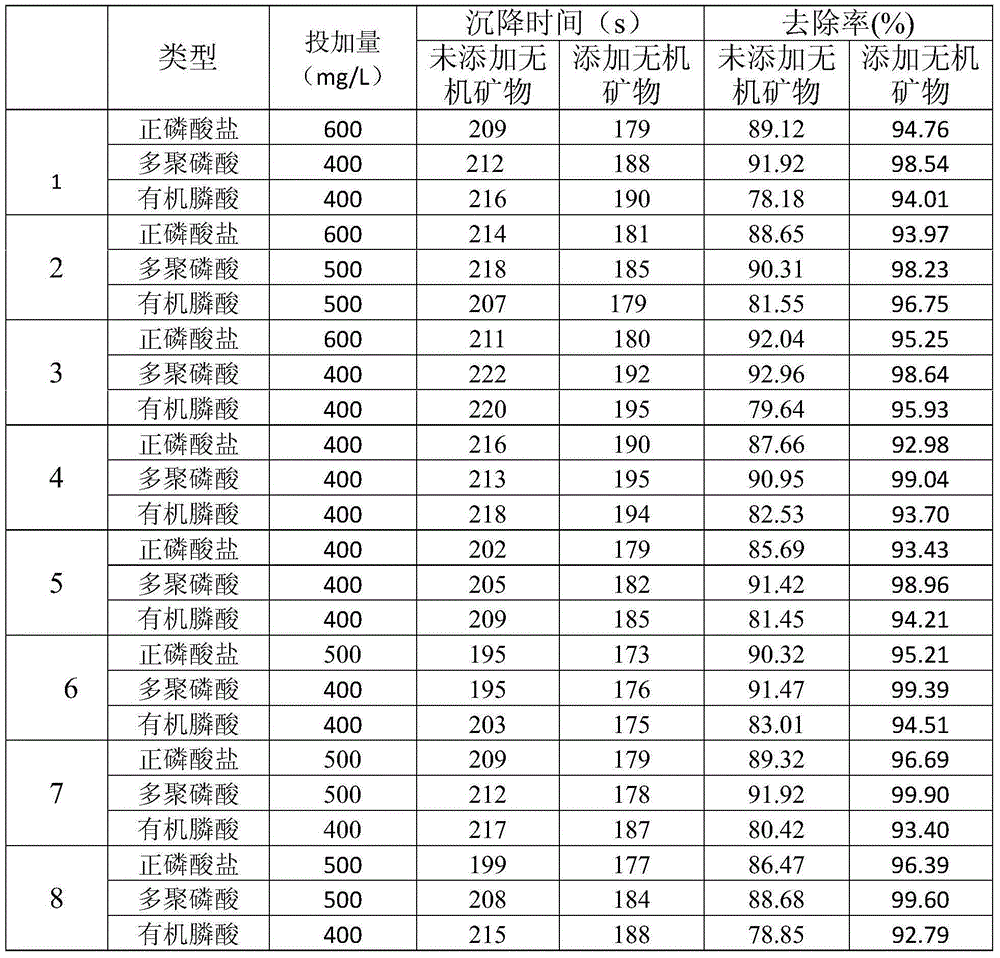

[0032] Take 1L of the sewage quality of the simulated circulating water system prepared above, add the above-mentioned inorganic mineral phosphorus removal agent according to the dosage in Table 2, stir for 1min, and stand at room temperature for 30min, then take the supernatant and use molybdate colorimetry The method was used for analysis, and the analysis results were all expressed as PO 4 3- For the results, see Table 2.

[0033] Table 2 is the water quality analysis result after adding phosphorus removal agent ...

Embodiment 2

[0037] Taking 2000mg of inorganic mineral phosphorus removal agent as an example, it is made by fully mixing 1200mg of polyaluminum chloride (PAC), 500mg of bentonite, and 300mg of ferrous sulfate, of which polyaluminum chloride (PAC) accounts for 60% of the total mass , bentonite accounted for 25%, ferrous sulfate accounted for 15%.

[0038] The dephosphorization agent is dissolved in water according to the mass concentration of 2%, and mixed before each use.

[0039] Take 1L of the sewage quality of the simulated circulating water system prepared above, add the above-mentioned inorganic mineral phosphorus removal agent according to the dosage in Table 3, stir for 1min, and let stand at room temperature for 30min, then take the supernatant and use molybdate colorimetry The method was used for analysis, and the analysis results were all expressed as PO 4 3- See Table 3 for the results.

[0040] Table 3 is the analysis result of sewage quality after adding phosphorus removal...

Embodiment 3

[0044] Taking 2000mg of inorganic mineral phosphorus removal agent as an example, it is made by fully mixing 1200mg of polyaluminum chloride (PAC), 600mg of diatomaceous earth, and 200mg of ferrous sulfate, of which polyaluminum chloride (PAC) accounts for 60%, diatomaceous earth accounts for 30%, and ferrous sulfate accounts for 10%.

[0045] The dephosphorization agent is dissolved in water according to the mass concentration of 2%, and mixed before each use.

[0046] Take 1L of the sewage quality of the simulated circulating water system prepared above, add the above-mentioned inorganic mineral phosphorus removal agent according to the dosage in Table 4, stir for 1min, and stand at room temperature for 30min, then take the supernatant and use molybdate colorimetry The method was used for analysis, and the analysis results were all expressed as PO4 3- See Table 4 for the results.

[0047] Table 4 shows the results of sewage quality analysis after adding phosphorus removal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com