A method for removing synthetic musk in sewage

A technology for synthesizing musk and sewage, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of synthetic musk pollution, secondary pollution, high cost, etc., and improve settlement Effects of adsorption efficiency, strength improvement, and property improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

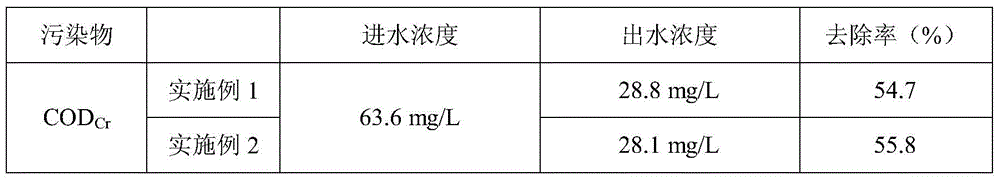

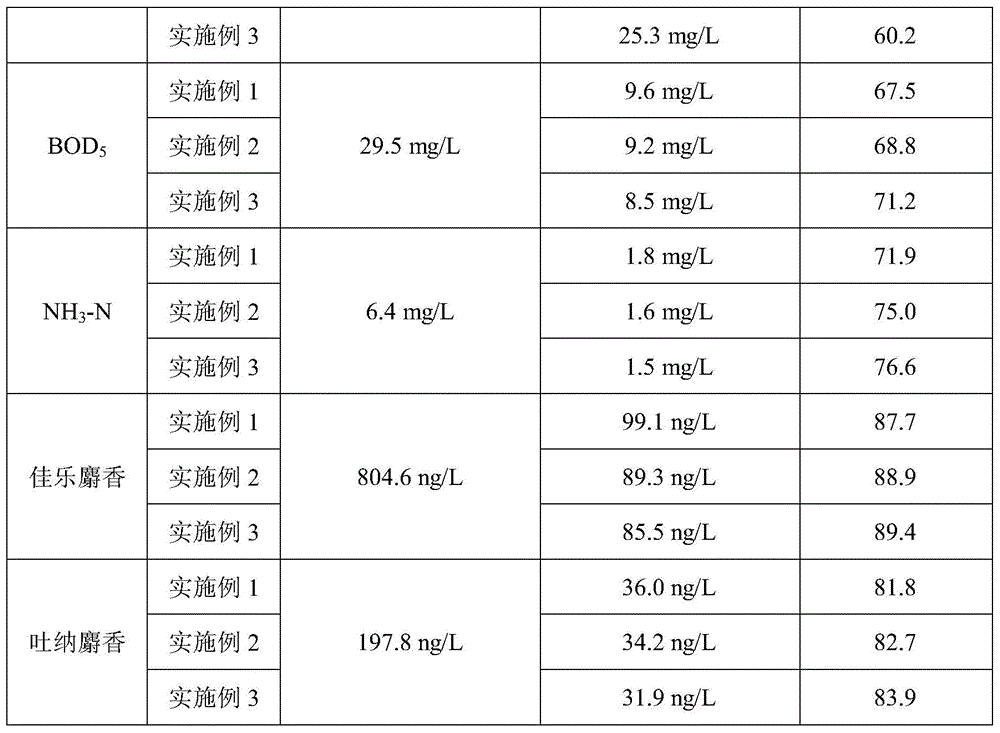

Embodiment 1

[0066] 1. Expanded culture of Bacillus subtilis

[0067] Prepare the solid medium according to the following ratio: beef extract 5g, peptone 10g, NaCl 5g, agar powder 15g, add water to 1000mL; sterilize the solid medium at 121°C for 30min; After 30 minutes, turn on the fluorescent lamp, burn the inoculation needle red on the alcohol lamp, dip in the water sample of Bacillus subtilis, streak the inoculation on the flat medium and the slant medium, and incubate in the constant temperature incubator for 24 hours.

[0068] 2. Centrifuge the dominant Bacillus subtilis that has completed the expanded culture to obtain wet thallus, and the concentration of wet thallus is 8.6×10 5 CFU / mL.

[0069] 3. Take by weighing 400 mg of wet thallus in a beaker, add 45 mg cellulose, 45 mg 101 support, 10 mg6201 support, stir evenly with a glass rod, add 1440 mg activated sludge, 160 mg powder lignite-based activated carbon, Stir well to get a viscous mixed raw material;

[0070] Wherein, the ...

Embodiment 2

[0073] 1. Expanded culture of Bacillus subtilis

[0074] Prepare the solid medium according to the following ratio: beef extract 5g, peptone 10g, NaCl 5g, agar powder 15g, add water to 1000mL; sterilize the solid medium at 121°C for 30min; After 30 minutes, turn on the fluorescent lamp, burn the inoculation needle red on the alcohol lamp, dip in the water sample of Bacillus subtilis, streak the inoculation on the flat medium and the slant medium, and incubate in the constant temperature incubator for 24 hours.

[0075] 2. Centrifuge the dominant Bacillus subtilis that has completed the expanded culture to obtain wet thallus, and the concentration of wet thallus is 6.2×10 6 CFU / mL.

[0076] 3. Take by weighing 900 mg of wet thallus in a beaker, add 35 mg cellulose, 35 mg 101 support, 30 mg6201 support, stir evenly with a glass rod, add 1080 mg activated sludge, 270 mg powder lignite-based active carbon, Stir well to get a viscous mixed raw material;

[0077] Wherein, the mas...

Embodiment 3

[0080] 1. Expanded culture of Bacillus subtilis

[0081] Prepare the solid medium according to the following ratio: beef extract 5g, peptone 10g, NaCl 5g, agar powder 15g, add water to 1000mL; sterilize the solid medium at 121°C for 30min; After 30 minutes, turn on the fluorescent lamp, burn the inoculation needle red on the alcohol lamp, dip in the water sample of Bacillus subtilis, streak the inoculation on the flat medium and the slant medium, and incubate in the constant temperature incubator for 24 hours.

[0082] 2. Centrifuge the dominant Bacillus subtilis that has completed the expanded culture to obtain wet thallus, and the concentration of wet thallus is 2.5×10 7 CFU / mL.

[0083] 3. Weigh 566.7 mg of the prepared wet bacteria in a beaker, add 40 mg of cellulose, 40 mg of 101 support, 20 mg of 6201 support, stir evenly with a glass rod, add 1128.9 mg of activated sludge and 198.3 mg of powdered lignite base activated carbon, fully stirred evenly to obtain viscous mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com