Method for preparing photocatalyst for treating petroleum pollutants in water

A photocatalyst, petroleum-based technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of high cost and harsh preparation conditions, and achieve absorption Wide range, simple preparation steps, high activity and longevity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

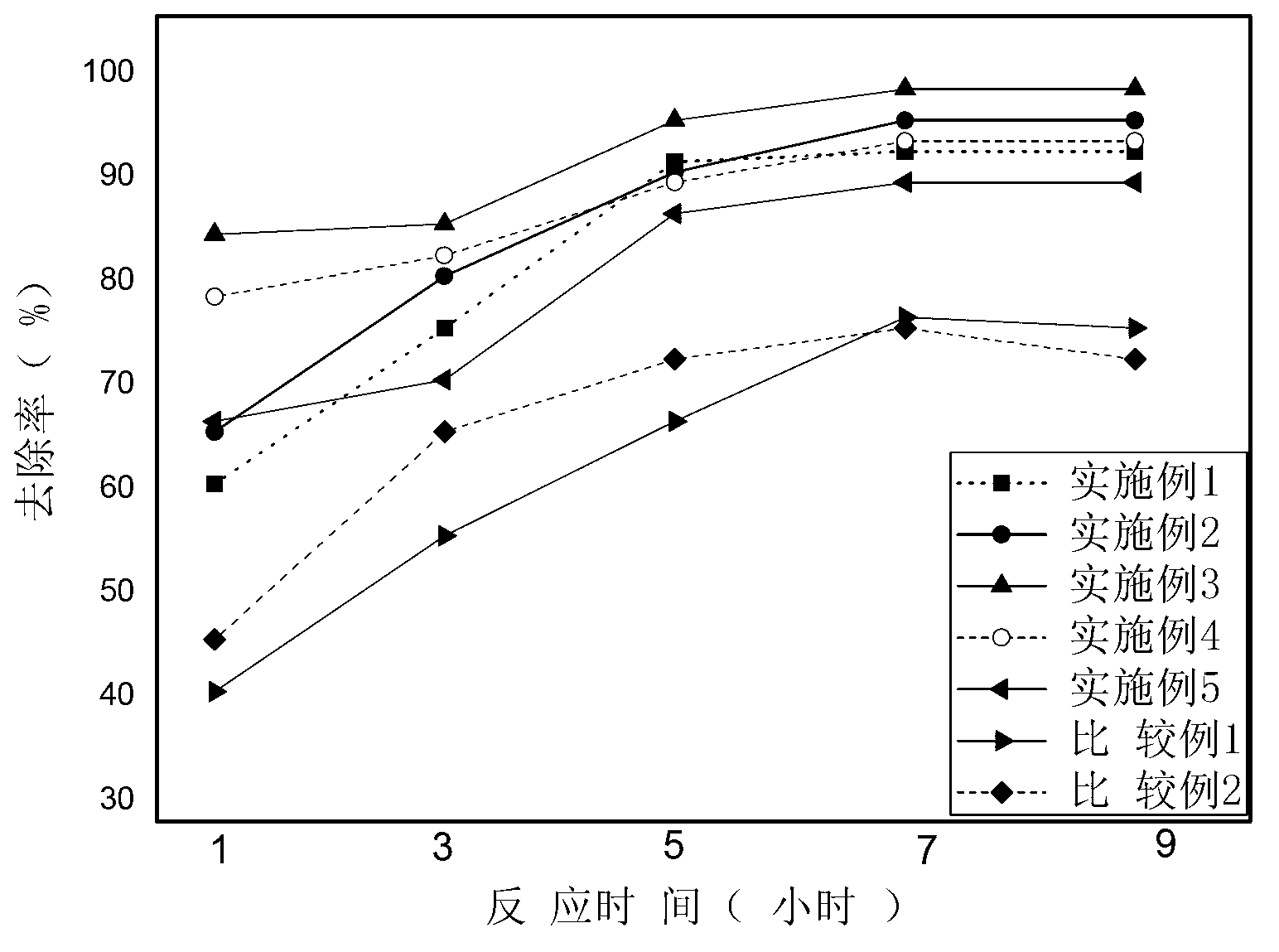

Examples

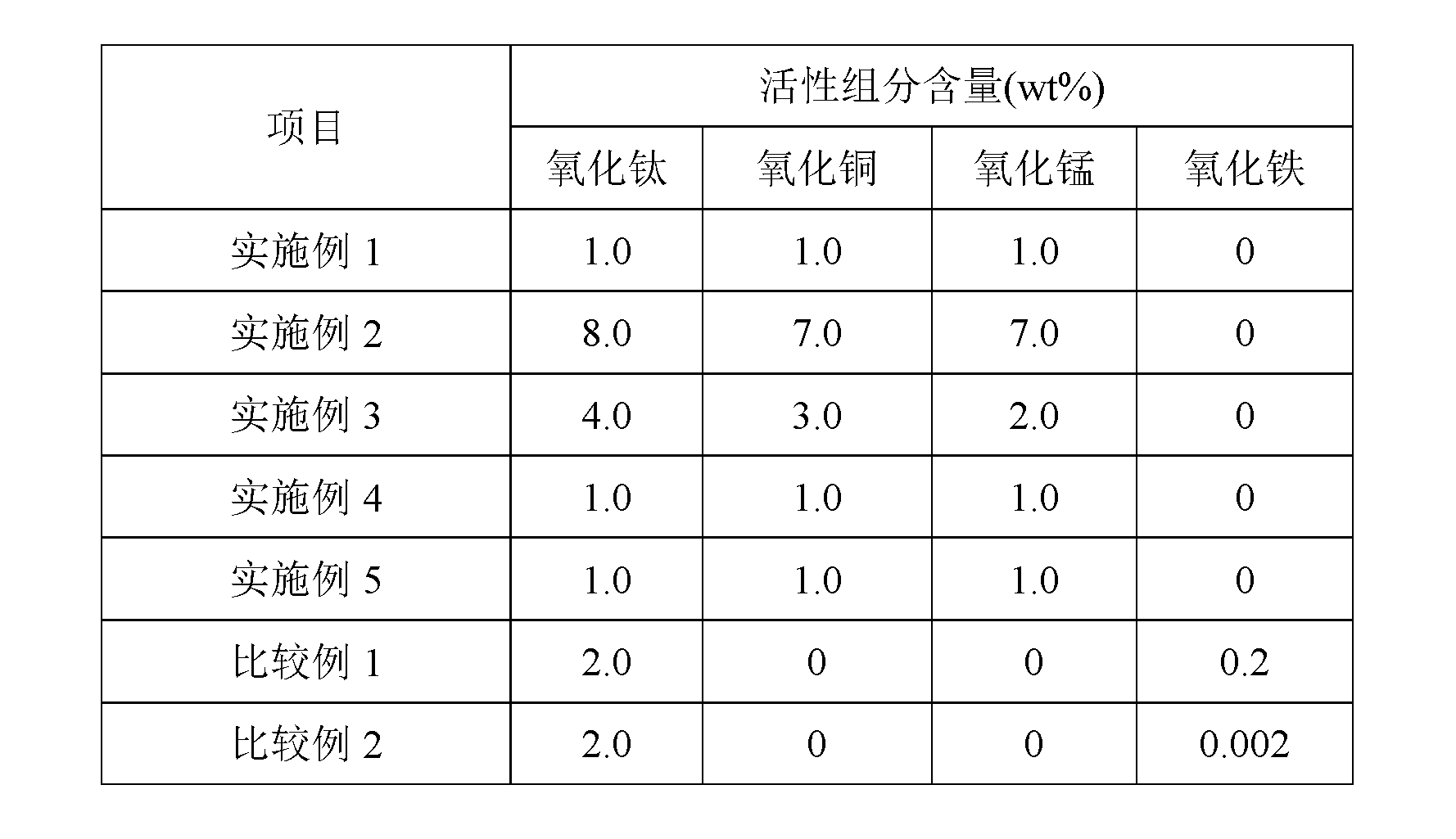

Embodiment 1

[0030] Take 10 g of titanyl sulfate, and use 300 g of deionized water to ultrasonically decompose and dissolve it into a solution. Add 10% ammonia water to adjust the pH of the reaction system to 9, precipitate for 15 min, and centrifuge to wash the precipitate until the conductivity of the eluate is below 20 μS / cm. Add 200ml of deionized water to the obtained white precipitate to make a slurry, add 15ml of hydrogen peroxide dropwise, and adjust the pH value to 7 with concentrated ammonia water to obtain a bright yellow transparent titanium sol.

[0031] Get 12g of copper nitrate solid, 18g of 50% manganese nitrate solution, add 20g of deionized water to dissolve into a solution, add 8g of 10% potassium permanganate solution under stirring conditions, and after reacting for 30 minutes, add 10% NaOH solution dropwise to adjust When the pH value of the slurry reaches 10, the stirring is stopped, and the slurry is spray-dried to obtain a composite metal catalyst precursor.

[0032...

Embodiment 2

[0035] Take 80g of titanyl sulfate, ultrasonically decompose and dissolve it into a solution with 2000g of deionized water. Add 5% ammonia water to adjust the pH value of the reaction system to 9, precipitate for 30 min, and centrifuge to wash the precipitate until the conductivity of the eluate is below 20 μS / cm. Add 1200ml of deionized water to the obtained white precipitate to make a slurry, add 100ml of hydrogen peroxide dropwise, and adjust the pH value to 7 with concentrated ammonia water to obtain a bright yellow transparent titanium sol.

[0036] Get copper nitrate solid 84g, 50% manganese nitrate solution 126g, add deionized water 140g to dissolve into solution, add 10% potassium permanganate solution 56g under stirring condition, after reacting for 60 minutes, add dropwise 30% NaOH solution to adjust When the pH value of the slurry reaches 12, the stirring is stopped, and the slurry is spray-dried to obtain a composite metal catalyst precursor.

[0037] Get 400g foa...

Embodiment 3

[0040] Take 40g of titanyl sulfate, and use 1000g of deionized water to ultrasonically decompose and dissolve it into a solution. Add 10% ammonia water to adjust the pH of the reaction system to 8, precipitate for 30 min, and centrifuge to wash the precipitate until the conductivity of the eluate is below 20 μS / cm. Add 800 ml of deionized water to the obtained white precipitate to make a slurry, add 60 ml of hydrogen peroxide dropwise, and adjust the pH value to 7 with concentrated ammonia water to obtain a bright yellow transparent titanium sol.

[0041] Get 36g of copper nitrate solid, 24g of 50% manganese nitrate solution, add 160g of deionized water to dissolve into a solution, add 64g of 10% potassium permanganate solution under stirring condition, after reacting for 60 minutes, add dropwise 30% NaOH solution to adjust When the pH value of the slurry reaches 12, the stirring is stopped, and the slurry is spray-dried to obtain a composite metal catalyst precursor.

[0042...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com