Nano zero valent iron @ molecular sieve composite material and preparation method and applications thereof

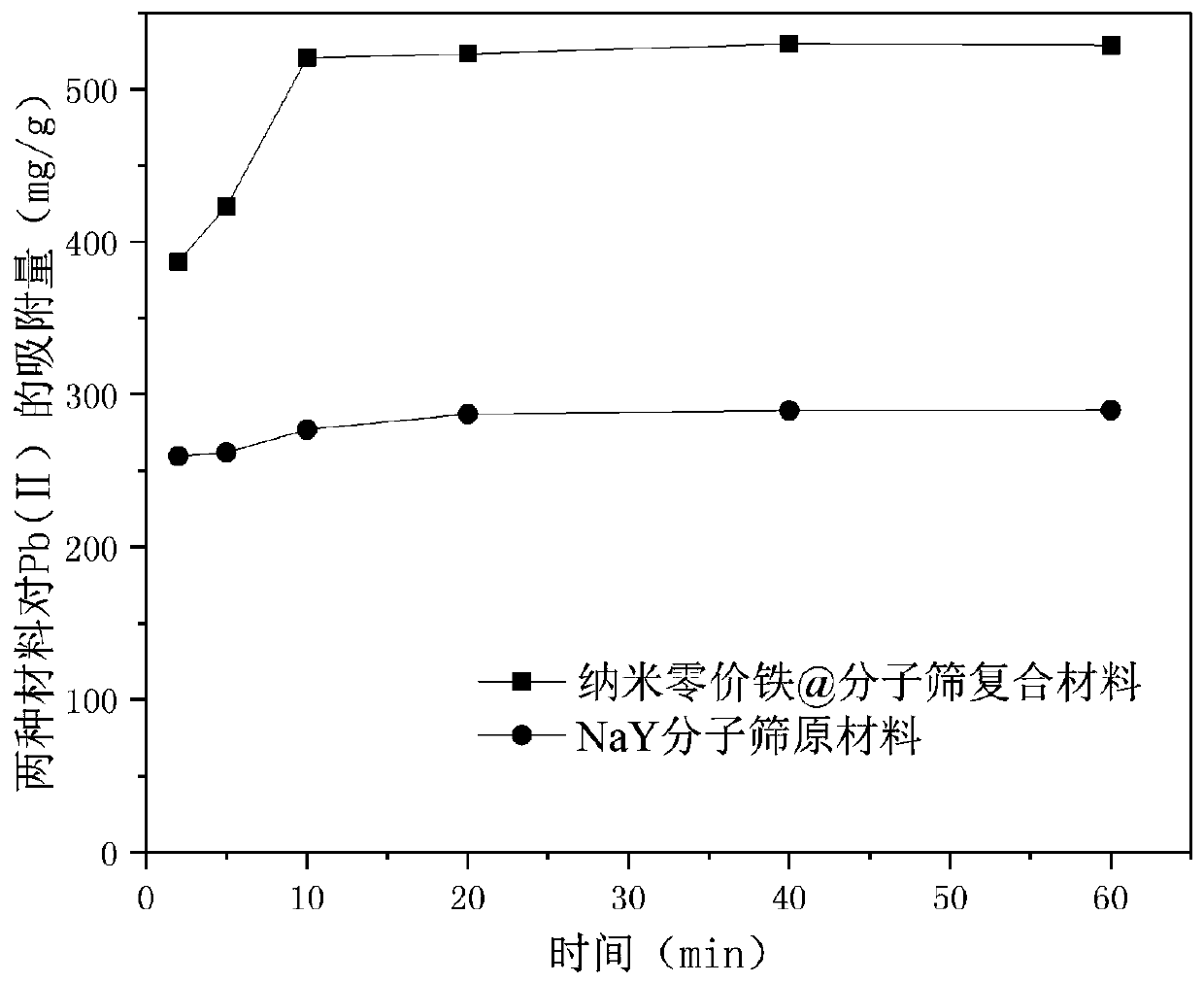

A nano-zero-valent iron and composite material technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, water pollutants, etc. Air contact, many active sites, avoid contact oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

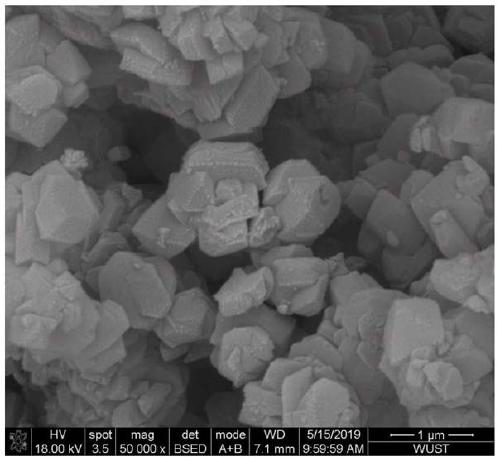

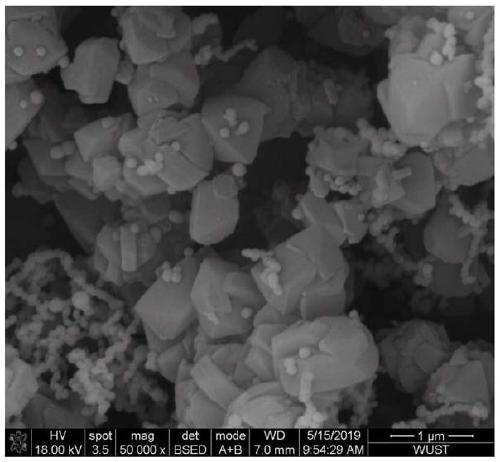

Image

Examples

Embodiment 1

[0046] The preparation method is as follows:

[0047] (1) Prepare a ferrous sulfate solution with a concentration of 1mol / L and a pH value of 3.0, add pretreated molecular sieve NaY to the iron salt solution according to the mass ratio of iron to molecular sieve 1:0.2, and mechanically stir under nitrogen protection 2h to exchange iron ions into molecular sieves to obtain a mixture A of iron salts and molecular sieves.

[0048] (2) Suction filtration of the mixed solution A for solid-liquid separation, rinse the separated solid twice with deionized water, transfer the solid to a three-necked flask, and add 40 mL of distilled water to the three-necked flask to obtain a mixed reaction solution , under the conditions of nitrogen protection and mechanical stirring, in the three-necked flask, the material ratio of iron and reducing agent is 1:2, and the sodium borohydride solution of 1mol / L is uniformly dropped into the mixed reaction solution, and after the dropwise addition is co...

Embodiment 2

[0055] (1) Prepare a ferrous chloride solution with a concentration of 0.5mol / L and a pH value of 3.1, add pretreated molecular sieve NaY to the iron salt solution at a mass ratio of iron to molecular sieve of 1:1, and under nitrogen protection Stir mechanically for 3 hours to exchange iron ions into molecular sieves to obtain a mixture A of iron salts and molecular sieves.

[0056] (2) Suction filtration of the mixed solution A for solid-liquid separation, rinse the separated solid with deionized water for 3 times, transfer the solid to a three-necked flask, and add 30 mL of distilled water to the three-necked flask to obtain a mixed reaction solution , under the conditions of nitrogen protection and mechanical stirring, in the three-necked flask, the material ratio of iron and reducing agent is 1:2, and the sodium borohydride solution of 0.5mol / L is uniformly dropped into the mixed reaction solution, and the dropwise addition After that, the mechanical stirring was continued...

Embodiment 3

[0060] (1) Prepare a ferric sulfate solution with a concentration of 0.2mol / L, add pretreated molecular sieve NaA to the iron salt solution at a mass ratio of iron to molecular sieve of 1:5, and mechanically stir for 4 hours to exchange iron ions into molecular sieves to obtain Mixture A of iron salt and molecular sieve.

[0061] (2) Suction filtration of the mixed solution A for solid-liquid separation, rinse the separated solid with deionized water for 3 times, transfer the solid to a three-necked flask, and add 50 mL of distilled water to the three-necked flask to obtain a mixed reaction solution , under the conditions of nitrogen protection and mechanical stirring, in the three-necked flask, the material ratio of iron and reducing agent is 1:3, and the sodium borohydride solution of 0.4mol / L is uniformly dripped into the mixed reaction solution, and after adding After that, the mechanical stirring was continued for 35 minutes to obtain the mixed solution B.

[0062] (3) S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com