Method for manufacturing nickel-molybdenum alloy seal head

A technology of nickel-molybdenum alloy and manufacturing method, which is applied in the field of nickel-molybdenum alloy manufacturing head, can solve problems such as easy generation of cracks, achieve the effects of eliminating stress and softening materials, and ensuring production quality and performance.

Inactive Publication Date: 2012-11-21

NANJING DUBLE METAL EQUIP ENG

View PDF1 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The object of the present invention is to propose a method for making nickel-molybdenum alloy heads, in order to solve the problem of nickel-molybdenum alloys, especially high-strength B3 (N10675) nickel-molybdenum alloy series heads. The problem that cracks are easy to occur during the production process, the invention provides a production scheme for nickel-molybdenum alloys, especially B3 alloy series heads

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

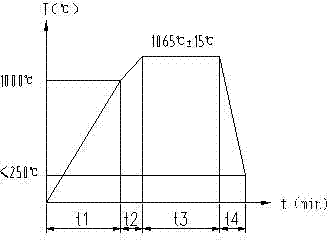

[0011] The following combination figure 1 Specific embodiments of the present invention will be described. figure 1 In the middle, t1 is the heating time of the empty furnace before the head is put into the furnace; t2 is the heating time of the head after being put into the furnace; t3 is the heat preservation time of the head in the furnace; t4 is the cooling time of the head in water after it is released from the furnace.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a method for manufacturing nickel-molybdenum alloy seal head. Technological conditions in the pressing process include that an empty furnace is heated to reach the temperature of 1000+ / -80 DEG C, a seal head disk enters the furnace at the temperature higher than or equal to 850 DEG C, the seal head disk is heated to reach the temperature of 1065+ / -15 DEG C along with the furnace after entering the furnace, the temperature is kept for 20-30min, and then the seal head disk is tapped off and is pressed at least twice while the seal head disk is hot. Technological conditions for solid solution of the pressed seal head includes that the empty furnace is heated to reach the temperature of 1000+ / -80 DEG C, the seal head and a seal head anti-deformation tool enter the furnace after being fixed at the temperature higher than or equal to 850 DEG C, the seal head is heated to reach the solid solution temperature of 1065+ / -15 DEG C along with the furnace after entering the furnace, and the seal head is tapped off and rapidly water-cooled after the temperature is kept for 30-45min, so that the high-strength nickel-molybdenum alloy seal head is obtained.

Description

technical field [0001] The invention relates to a method and a product for making a head made of nickel-molybdenum, in particular to a manufacturing process of the head. Background technique [0002] Nickel-molybdenum alloy (typically such as the HASTELLOY B-3 (N10675) nickel-molybdenum alloy material of the American Hansen (HAYNES) company, it has excellent corrosion resistance to hydrochloric acid at any temperature and concentration. At the same time it is resistant to sulfuric acid, acetic acid , acetic acid, formic acid, phosphoric acid and other non-oxidizing media also have good corrosion resistance. Moreover, due to the adjustment of its chemical composition, its thermal stability is compared with the original HASTELLOY B-2 ( N10665) alloy has been greatly improved. B3 (N10675) alloy has high resistance to pitting corrosion, stress corrosion cracking, knife corrosion and welding heat affected zone corrosion. [0003] Due to the good anti-acid properties of B3 (N1067...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C21D8/00C22F1/10

Inventor 张海峰经正霞齐骞邓家爱赵鲁

Owner NANJING DUBLE METAL EQUIP ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com