Halogen-free flame-retardant polypropylene material and preparation method thereof

A flame retardant polypropylene and polypropylene resin technology, applied in the field of polymer materials and their preparation, can solve problems such as affecting production efficiency, increasing production processes, increasing production costs, etc. Affect and ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0025] The halogen-free flame-retardant polypropylene material of this embodiment is made of the following components by weight:

[0026] 100kg of polypropylene resin, 14kg of piperazine diphosphate, 8kg of pentaerythritol diphosphate melamine salt, 2.5kg of melamine cyanurate, 2.5kg of organic montmorillonite, 10kg of EPDM rubber, 0.03kg The antioxidant 1010 and the antioxidant 168 of 0.07kg.

[0027] The preparation method of the above-mentioned halogen-free flame-retardant polypropylene material has the following steps:

[0028] ① Pour the above-mentioned components into the high-speed mixer according to the formula, start the motor, and control the agitator to rotate at 900 rpm for mixing until the friction heat generated by the mixing makes the temperature of the material rise to 90°C-100°C. Material cooling.

[0029] ② Feed the cooled mixture into a twin-screw extruder for melting and extrusion, and the extruded strips are cooled in a water tank, drawn into a pelletize...

Embodiment 2~ Embodiment 6)

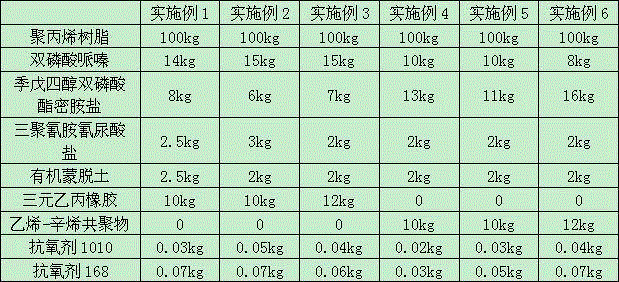

[0032] The preparation method of the halogen-free flame-retardant polypropylene material of each example is the same as that of Example 1, the difference lies in the weight ratio of each component, see Table 1 for details.

[0033] Table 1

[0034]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com