Preparation method of insulating and flame-retardant electric meter box shell material

A technology of shell material and electric meter box, which is applied in the field of preparation of insulating and flame-retardant electric meter box shell materials, can solve the problems of unbearable capacity of electric meter box, heating of household circuits and equipment, heating and ignition of contact points, etc. UV shielding function, long service life, reducing the effect of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

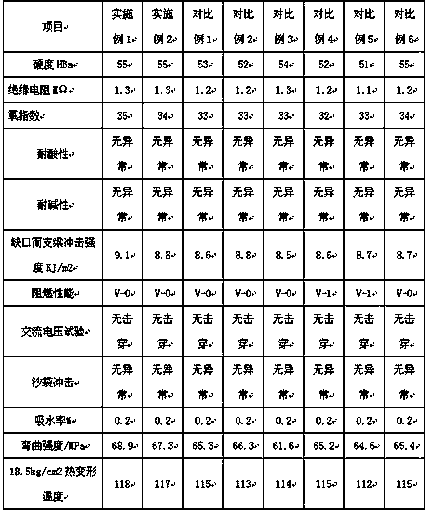

Examples

Embodiment 1

[0019] A method for preparing an insulating and flame-retardant electric meter box shell material, characterized in that it comprises the following steps: 1. Weigh each raw material according to the proportion, first take fluorinated graphene and citric acid, and uniformly disperse them in a 15% mass fraction In the propylene glycol aqueous solution, after mechanical stirring for 5 minutes, add thioacetamide, and then add magnesium chloride and magnesium hydroxide after stirring for 15 minutes, put the mixed liquid into a ball mill jar for ball milling for 3 hours, after ball milling, dry at 90°C for 5 hours, then put it into polytetrafluoroethylene In an ethylene reaction kettle, heat up to 220°C at a rate of 10°C / min in a microwave high-temperature muffle furnace, keep warm for 3 hours and then cool to obtain a navy blue solid powder. Dry in an air drying oven at 90°C for 2 hours to obtain the fluorinated graphene whisker composite material; 2. Under nitrogen protection, mix ...

Embodiment 2

[0028] A method for preparing an insulating flame-retardant electric meter box shell material, characterized in that it comprises the following steps: 1. Weigh each raw material according to the proportion, first take fluorinated graphene and citric acid, and uniformly disperse them in a 12% mass fraction In the propylene glycol aqueous solution, after mechanical stirring for 5 minutes, add thioacetamide, and then add magnesium chloride and magnesium hydroxide after stirring for 15 minutes, put the mixed liquid into a ball mill jar for ball milling for 3 hours, after ball milling, dry at 90°C for 5 hours, then put it into polytetrafluoroethylene In an ethylene reaction kettle, heat up to 220°C at a rate of 10°C / min in a microwave high-temperature muffle furnace, keep warm for 3 hours and then cool to obtain a navy blue solid powder. Dry in an air drying oven at 80°C for 1 hour to obtain the fluorinated graphene whisker composite material; 2. Under the protection of nitrogen, mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com