A kind of microcapsule intumescent flame retardant and its preparation method and application

An intumescent flame retardant and microcapsule technology, applied in the field of flame retardants, can solve the problems of post-processing of polymers and other unfavorable properties, the influence of processing temperature and processing temperature, reaching 15% or even higher, and achieving good flame retardant synergy , uniform distribution and short ignition time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

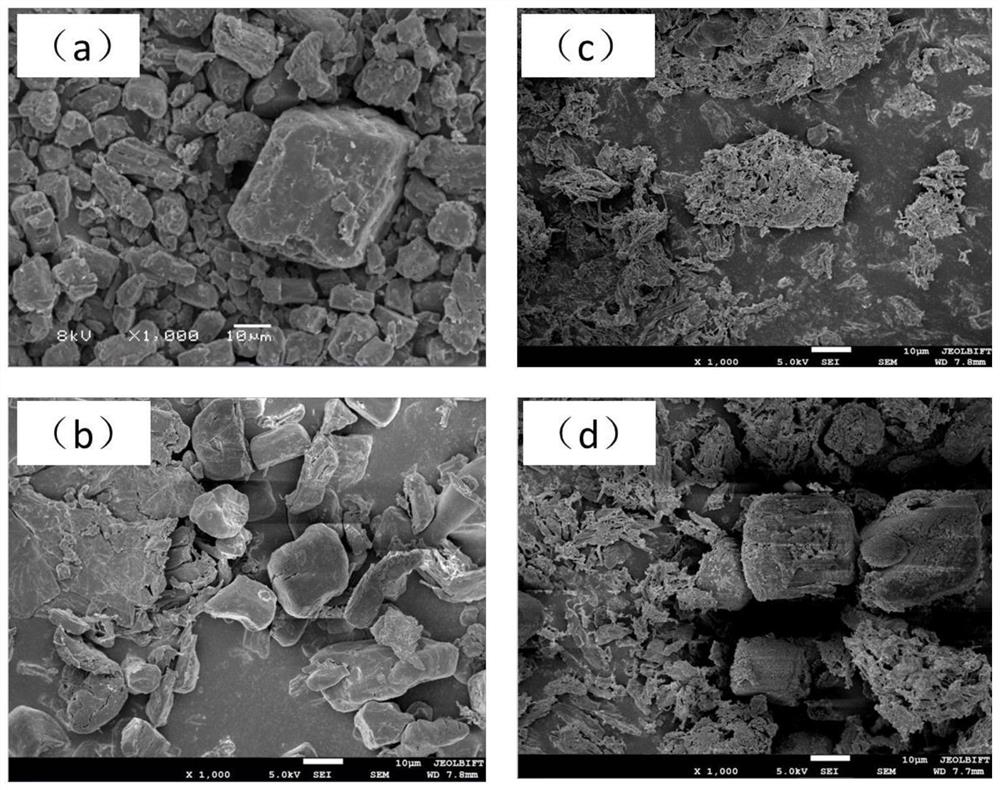

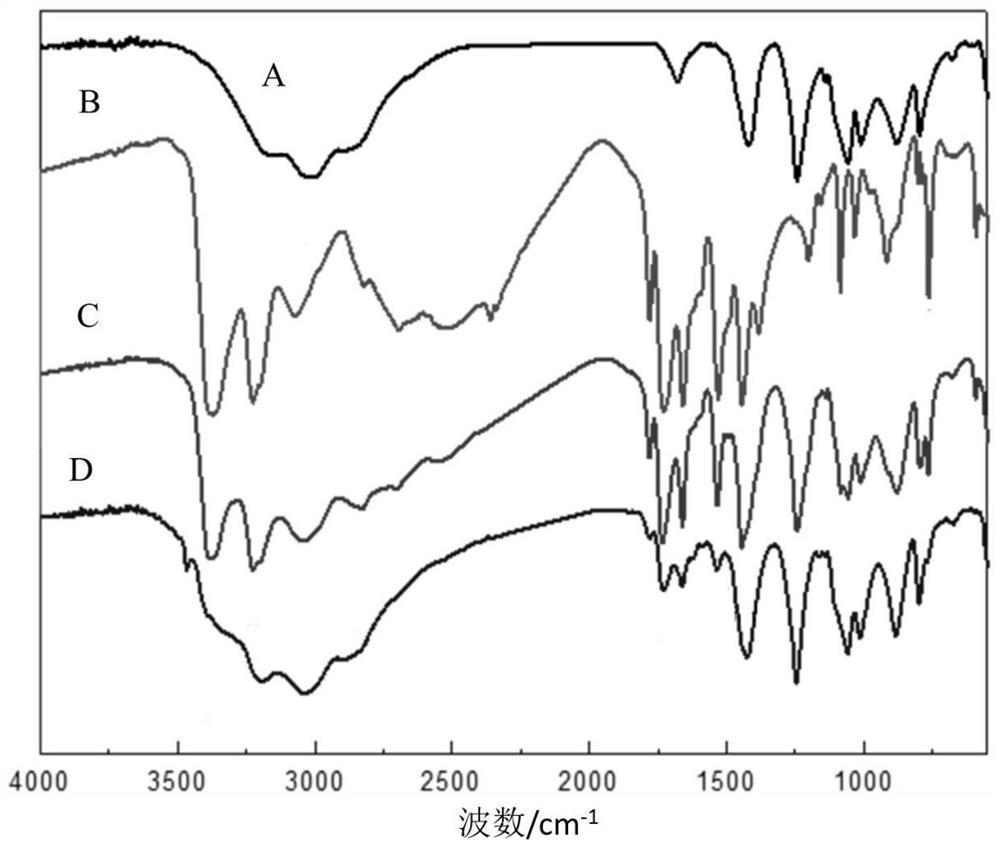

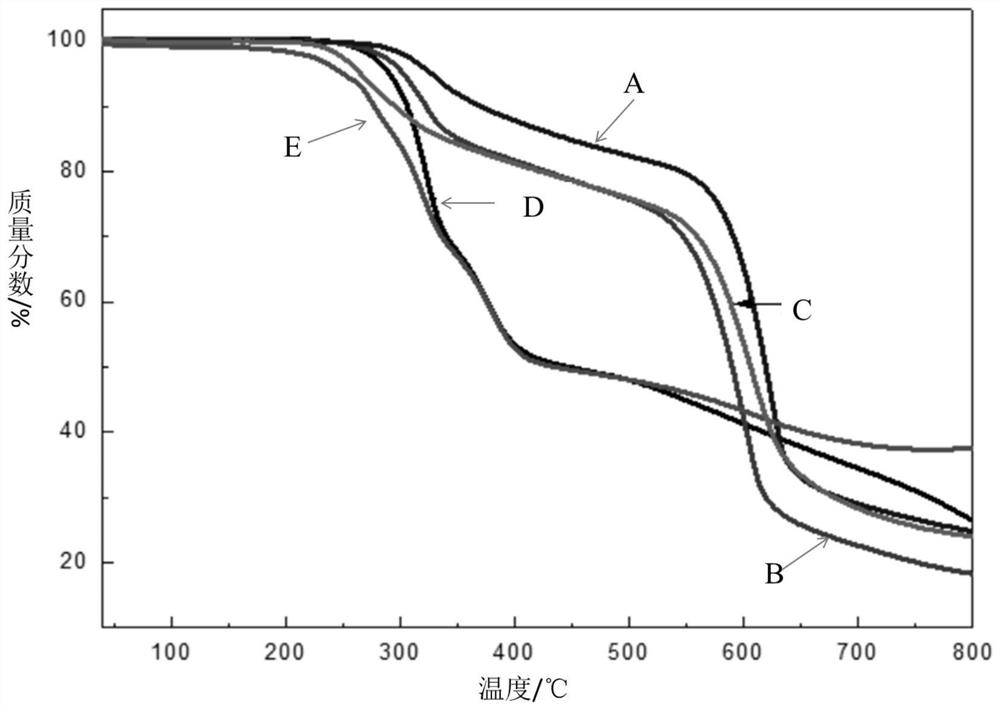

[0019] According to the present invention, the preparation method of the microcapsule intumescent flame retardant comprises: using an acid source and a carbon source to prepare a core material, and then coating the core material with a capsule material prepared from a gas source to obtain the microcapsule intumescent flame retardant flame retardant.

[0020] In the present invention, the microcapsule intumescent flame retardant is embodied by the expansion agent flame retardant in the form of microcapsules. The advantages of good combustion effect.

[0021] According to a preferred embodiment of the present invention, the core material is prepared by mixing the acid source and the carbon source, wherein the mass ratio of the acid source to the carbon source is (2-8):1, preferably (3-6):1.

[0022] According to a preferred embodiment of the present invention, the acid source is selected from melamine polyphosphate, 9,10-dihydro-9-oxa-10-phosphonophenanthrene-succinic acid (DDP...

Embodiment 1

[0069] Mix 60ml of acetone and 30ml of water to prepare a solvent, add 10g of DDP to the solvent, stir at 65°C to obtain a solution containing DDP; disperse 2g of MCC in deionized water to obtain a solution containing MCC;

[0070] After the DDP is dissolved, add the MCC-containing solution dropwise to the DDP-containing solution, and the dropwise addition is completed within 10 minutes to obtain a mixed solution, and the mixed solution is stirred for 2 hours; after the stirring is completed, the mixed solution is cooled to 20 °C, place the mixed solution in a water bath at 20 °C and continue to stir for 10 h; after the stirring is completed, carry out centrifugal drying to the mixed solution to obtain a core material;

[0071] Add 0.99g of melamine into 10ml of deionized water, and ultrasonically disperse to obtain a melamine dispersion;

[0072] Take 8g of core material and add it to deionized water, ultrasonically disperse it, then raise the temperature to 90°C, add 1.01g o...

Embodiment 2

[0074] Repeat the preparation process of Example 1, the only difference is that the content of melamine is 2.97g, and that of cyanuric acid is 3.03g. Other processes are the same as in Example 1 to obtain a microcapsule intumescent flame retardant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com