Intumescent fireproof paint and preparation method thereof

A kind of technology of fireproof coating and expansion type, applied in the direction of fireproof coating, coating, etc., can solve the problems of poor storage stability, non-dense carbon layer, poor water resistance, etc., and achieve the effect of stable storage, high density strength and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

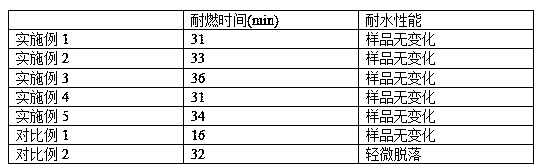

Examples

Embodiment 1

[0035] Calculated in parts by weight, the intumescent fireproof coating includes 30 parts of water, 16 parts of emulsion, 7 parts of pigment, 5 parts of isodecyl diphenyl phosphate, 41 parts of intumescent flame retardant, 0.6 part of dispersant, defoamer 0.5 parts, 0.5 parts of thickener, 0.3 parts of pH regulator, 0.2 parts of bactericide, and 0.5 parts of film-forming aid; wherein the intumescent flame retardant consists of: 12 parts of pentaerythritol, 16 parts of ammonium polyphosphate, and 13 parts of melamine;

[0036] The emulsion is compounded with vinegar-acrylic emulsion and partial chloride emulsion in a ratio of 4:1; the pigment is rutile titanium dioxide; the dispersant sodium pyrophosphate; the defoamer is tributyl phosphate; The thickener is a combination of hydrophobically modified alkali-swellable thickener, cellulose, and attapulgite, the ratio is: 2:0.8:1, the film-forming aid is lauryl alcohol ester; the pH regulator is ammonia water , the fungicide is 2-met...

Embodiment 2

[0040] Calculated in parts by weight, the intumescent fire retardant coating includes 30 parts of water, 16 parts of emulsion, 7 parts of pigment, 8 parts of isodecyl diphenyl phosphate, 38 parts of intumescent flame retardant, 0.6 part of dispersant, defoamer 0.5 parts, 0.2 parts of thickener, 0.3 parts of pH regulator, 0.2 parts of bactericide, and 0.5 parts of film-forming aid; wherein the intumescent flame retardant consists of: 11 parts of pentaerythritol, 15 parts of ammonium polyphosphate, and 12 parts of melamine;

[0041] The emulsion is compounded with vinegar-acrylic emulsion and partial chloride emulsion in a ratio of 4:1; the pigment is rutile titanium dioxide; the dispersant sodium pyrophosphate; the defoamer is tributyl phosphate; The thickener is a combination of hydrophobically modified alkali-swellable thickener, cellulose, and attapulgite, and the ratio is: 2:0.8:1. The film-forming aid is lauryl alcohol ester; the pH regulator is ammonia water. The fungicid...

Embodiment 3

[0044] Calculated in parts by weight, the intumescent fireproof coating includes 30 parts of water, 16 parts of emulsion, 7 parts of pigment, 6 parts of isodecyl diphenyl phosphate, 42 parts of intumescent flame retardant, 0.6 part of dispersant, defoamer 0.5 parts, 0.2 parts of thickener, 0.3 parts of pH regulator, 0.2 parts of bactericide, and 0.5 parts of film-forming aid; wherein the intumescent flame retardant consists of: 13 parts of pentaerythritol, 16 parts of ammonium polyphosphate, and 13 parts of melamine;

[0045] The emulsion is compounded with vinegar-acrylic emulsion and partial chloride emulsion in a ratio of 4:1; the pigment is rutile titanium dioxide; the dispersant sodium pyrophosphate; the defoamer is tributyl phosphate; The thickener is a combination of hydrophobically modified alkali-swellable thickener, cellulose, and attapulgite, and the ratio is: 2:0.8:1. The film-forming aid is lauryl alcohol ester; the pH regulator is ammonia water. The fungicide is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com