Method for recovering and preparing carbon/carbon preform from carbon fiber reinforced resin matrix composite material

A technology for reinforcing resin matrix and composite materials, which is applied in the field of recycling and reuse of fiber-reinforced resin matrix composite materials, can solve the problems of insufficient recovery and reuse of resin matrix, damage, and failure of carbon fiber to obtain high-value reuse. , to achieve the effect of low equipment investment and process treatment cost and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

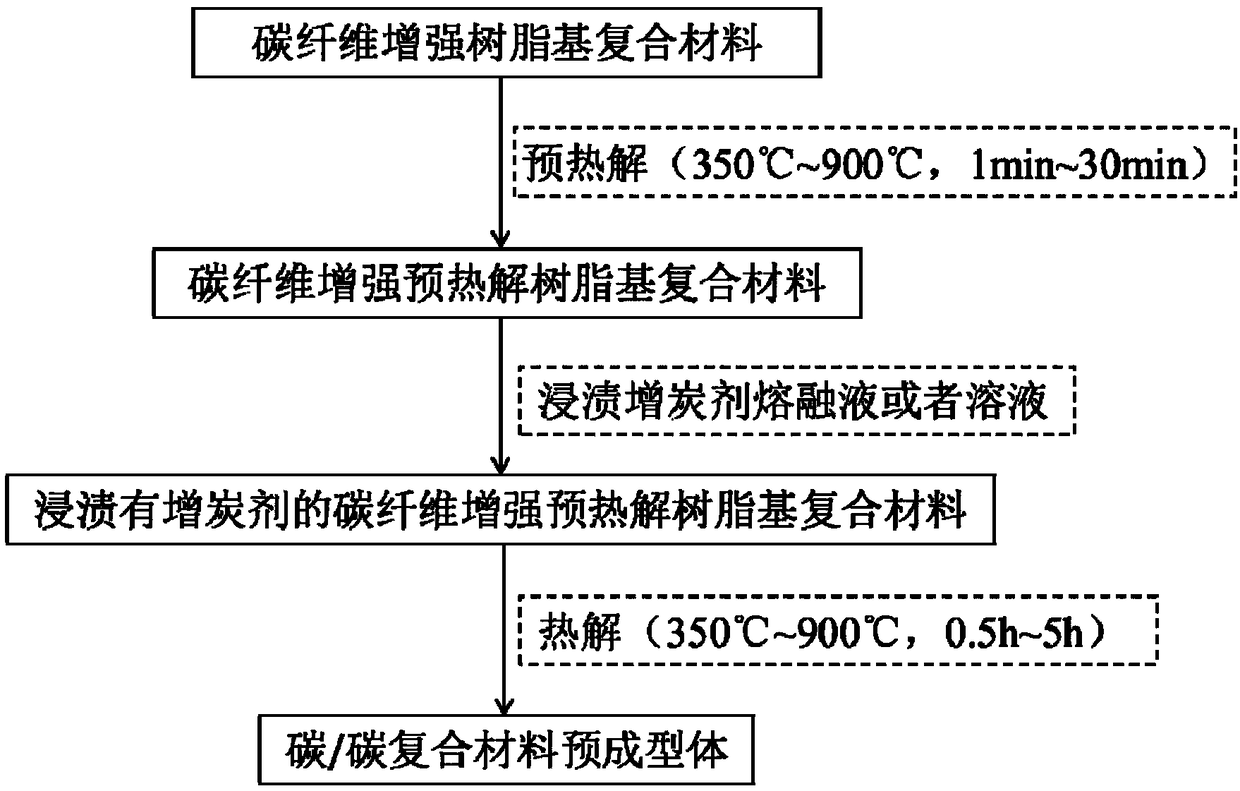

[0059] A carbon fiber reinforced resin matrix composite material of the present invention recycles and prepares the method for carbon / carbon preform, such as figure 1 shown, including the following steps:

[0060] (1) Weigh 10.984g of carbon fiber reinforced epoxy resin composite material block, place it in the pyrolysis furnace, close the furnace door, and feed argon gas after vacuuming, so that the pumping and inflation are repeated three times, and the air in the furnace is Completely exhaust to form an inert atmosphere environment, and continue to flow argon. Heat the carbon fiber reinforced epoxy resin composite material in the pyrolysis furnace to perform pre-pyrolysis. The pre-pyrolysis temperature is 350 ° C. After 5 minutes of constant temperature, stop heating to obtain the pre-pyrolysis product, which is lowered to room temperature with the furnace. At this time, the carbon fiber reinforced The epoxy resin composite material was pyrolyzed to produce holes, the weig...

Embodiment 2

[0065] A method for preparing a carbon / carbon preform by reclaiming a carbon fiber reinforced resin-based composite material of the present invention, the preparation process is basically the same as that of Example 1, the only difference being:

[0066]In step (1), take by weighing 10.484g of carbon fiber reinforced epoxy resin composite block, after pre-pyrolysis, the weight of the carbon fiber reinforced epoxy resin composite material with holes is 8.685g, and the epoxy resin matrix weight remains The rate is 69.62%.

[0067] In step (2), the carbon fiber reinforced pre-pyrolysis epoxy resin composite material with holes is placed in the carburant hexaphenoxycyclotriphosphazene melt (150 ° C), fully impregnated and step (3) After pyrolysis, the weight of the obtained carbon / carbon preform was 7.631 g, and the residual carbon rate of the epoxy resin matrix was 51.83%.

[0068] In this example, the surface of the recovered carbon / carbon preform is rich in deposited carbon, a...

Embodiment 3

[0070] A method for preparing a carbon / carbon preform by reclaiming a carbon fiber reinforced resin-based composite material of the present invention, the preparation process is basically the same as that of Example 1, the only difference being:

[0071] In step (1), take by weighing 11.171g of carbon fiber reinforced epoxy resin composite block, after pre-pyrolysis, the weight of the carbon fiber reinforced pre-pyrolysis epoxy resin composite material with holes is 8.804g, epoxy resin The matrix weight retention rate was 62.49%.

[0072] In step (2), the carbon fiber reinforced epoxy resin composite material with holes is placed in the carburant 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide melt (150°C ), after fully impregnated and pyrolyzed in step (3), the weight of the obtained carbon / carbon preform is 7.121g, and the residual carbon rate of the epoxy resin matrix is 35.82%.

[0073] In this example, the surface of the recovered carbon / carbon preform is rich in de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com