Production method of inorganic soil graft modified phenolic resin foam

A technology of phenolic resin foam and graft modification, which is applied in the field of kaolin and inorganic soil, which can solve the problems affecting the foam structure and thermal conductivity of the foam, and achieve the effects of improving thermal insulation performance, fire resistance performance and high closed cell rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

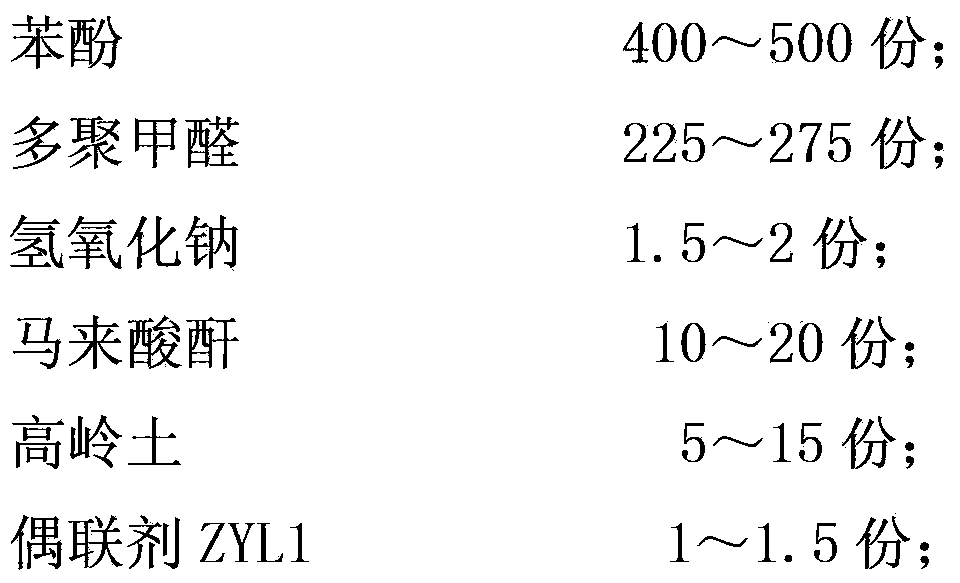

[0021] (1) Backup raw materials: 400kg of phenol, 225kg of paraformaldehyde, 1.5kg of sodium hydroxide, 10kg of maleic anhydride, 5kg of kaolin, 11kg of coupling agent ZYL, and 60kg of water;

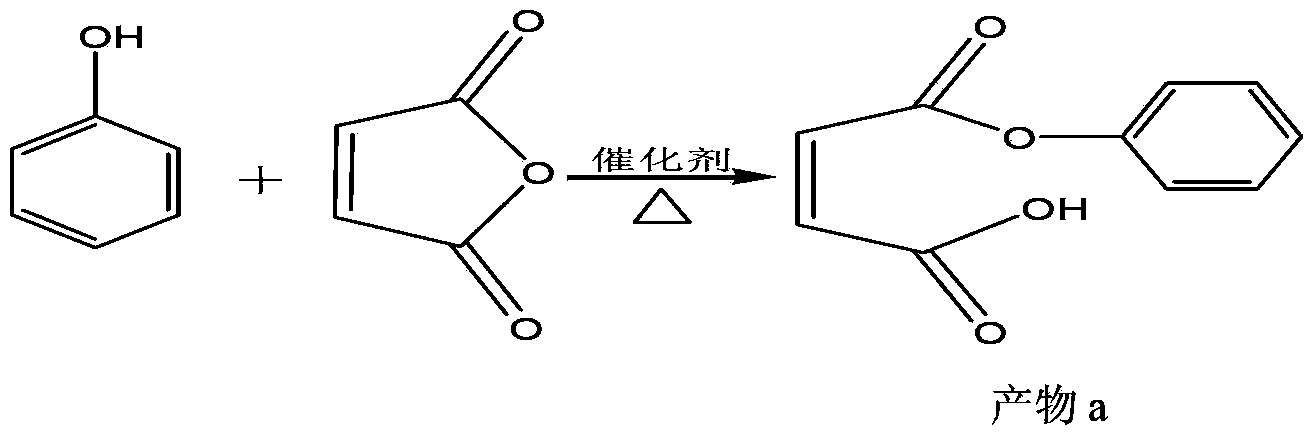

[0022] (2) Put the phenol, sodium hydroxide and water prepared in step (1) into the reaction kettle, heat up to 70-80° C., add the maleic anhydride prepared in step (1), and mix and stir for 1 hour. Added maleic anhydride reacts with the phenolic hydroxyl group of phenol in the described reactor, generates product a namely 3-phenyl-3-oxo-2-butenoic acid, and its reaction formula is:

[0023]

[0024] In the formula for phenol, Be maleic anhydride, catalyst is sodium hydroxide, and product a is 3-phenyl-3-oxo-2-butenoic acid;

[0025] (3), take the paraformaldehyde prepared in step (1) and divide it into three times, each time at an interval of 20 minutes, put it into the reaction kettle, control the temperature to 90°C and below, and throw it within 1 hour. Slowly raise the temp...

Embodiment 2

[0032] (1) Backup raw materials: 500kg of phenol, 275kg of paraformaldehyde, 2kg of sodium hydroxide, 20kg of maleic anhydride, 15kg of kaolin, 11.5kg of coupling agent ZYL, and 120kg of water;

[0033] Steps (2)~(4) are with embodiment 1;

[0034] (5), dehydration 70kg, obtain kaolin graft modified phenolic resin;

[0035] (6), get step (5) gained kaolin graft modified phenolic resin 40kg, get BD3088 polyether modified organopolysiloxane 1.3kg, n-pentane 2.5kg, and p-toluenesulfonic acid 0.8kg, phosphoric acid 0.8kg , 0.8kg of sulfuric acid, a total of 2.4kg, dissolved in 0.5kg of water, mixed and stirred evenly, injected into the preset mold, and foamed by conventional methods to obtain the finished inorganic soil grafted modified phenolic resin foam. The finished inorganic soil graft modified phenolic resin foam finished product of above-mentioned embodiment 1~2 is qualified through inspection, and inspection result is as shown in the following table:

[0036]

[0037]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com