Preparation method of injectable polypeptide hydrogel

A technology of hydrogel and aqueous solution, applied in the field of preparation of injectable polypeptide hydrogel, can solve the problems of increasing cost and reducing application effect, and achieve the effect of promoting formation, good biocompatibility and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1. Utilize solid-phase synthesis method, synthesize the polypeptide molecule EMK16-II of ion complementary type (sequence is (MEMEMKMK) 2 , where M represents methionine, which is a hydrophobic amino acid, E represents glutamic acid, which is a negatively charged hydrophilic amino acid, K represents lysine, which is a positively charged hydrophilic amino acid, and they are arranged alternately to form a Amphiphilic polypeptide molecules).

[0020] 2. The obtained polypeptide was dissolved in pure water, and freeze-dried to remove residual impurities during the synthesis process, thereby obtaining a solid sample powder.

[0021] 3. Dissolve the sample powder in sodium chloride solution (sodium chloride concentration is 3mM) and undergo ultrasonic treatment for 10 minutes (100W, 40,000Hz) until the sample is completely dispersed and dissolved. The concentration of EMK16-II in the final solution is 5mg / mL.

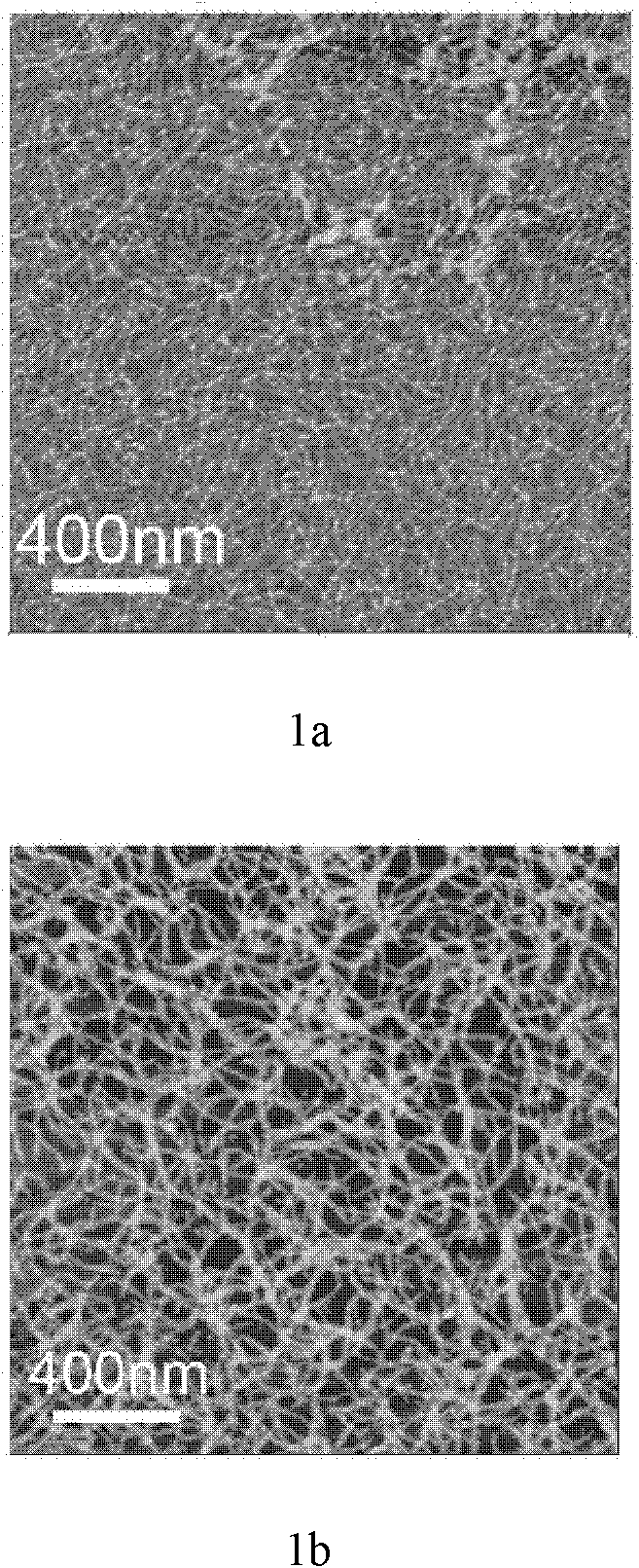

[0022] The above solution was left to stand for 1 hour to obta...

Embodiment 2

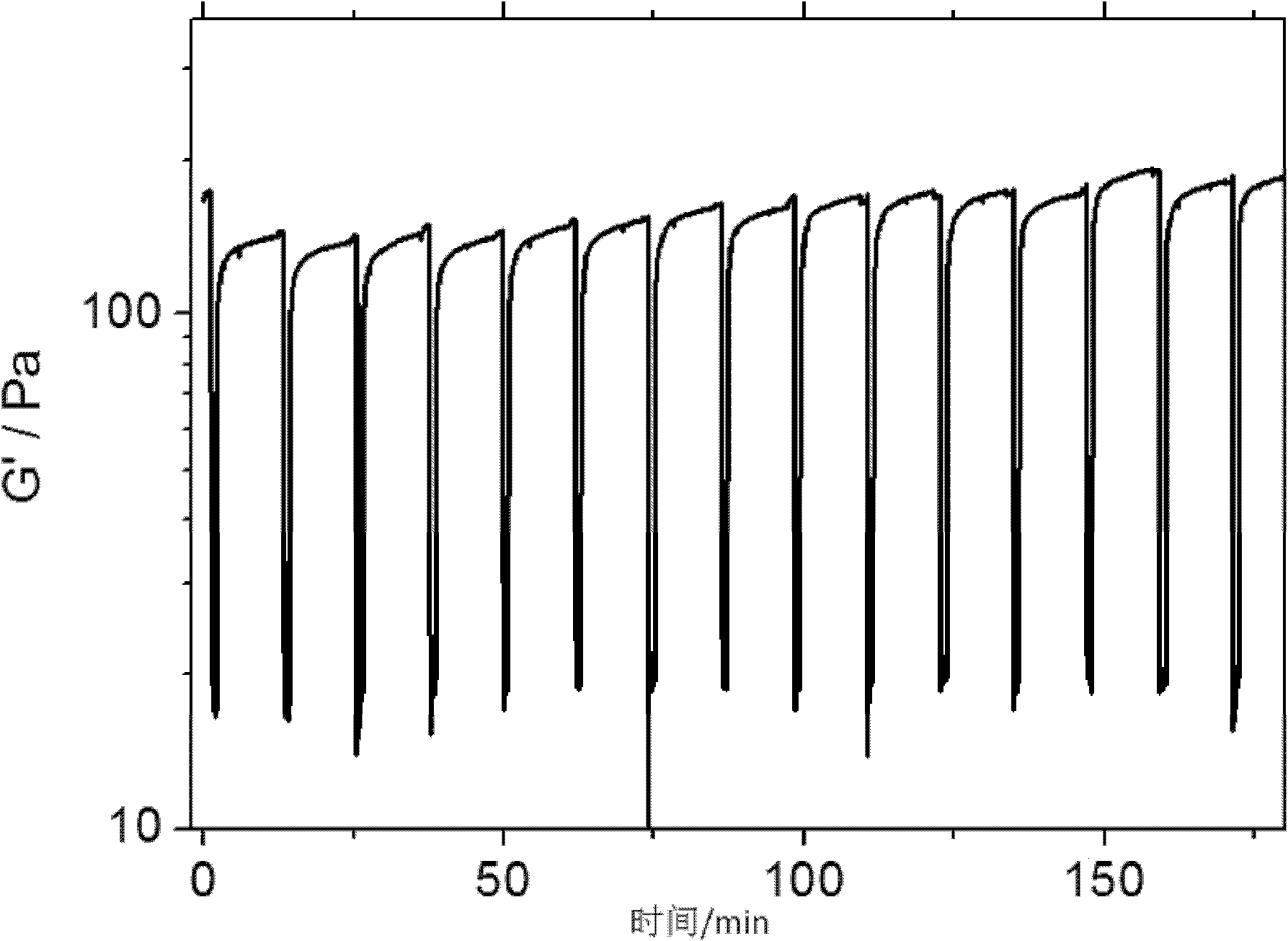

[0024] The concentration of EMK16-II was 30 mg / mL, and the rest of the experimental conditions were the same as in Example 1.

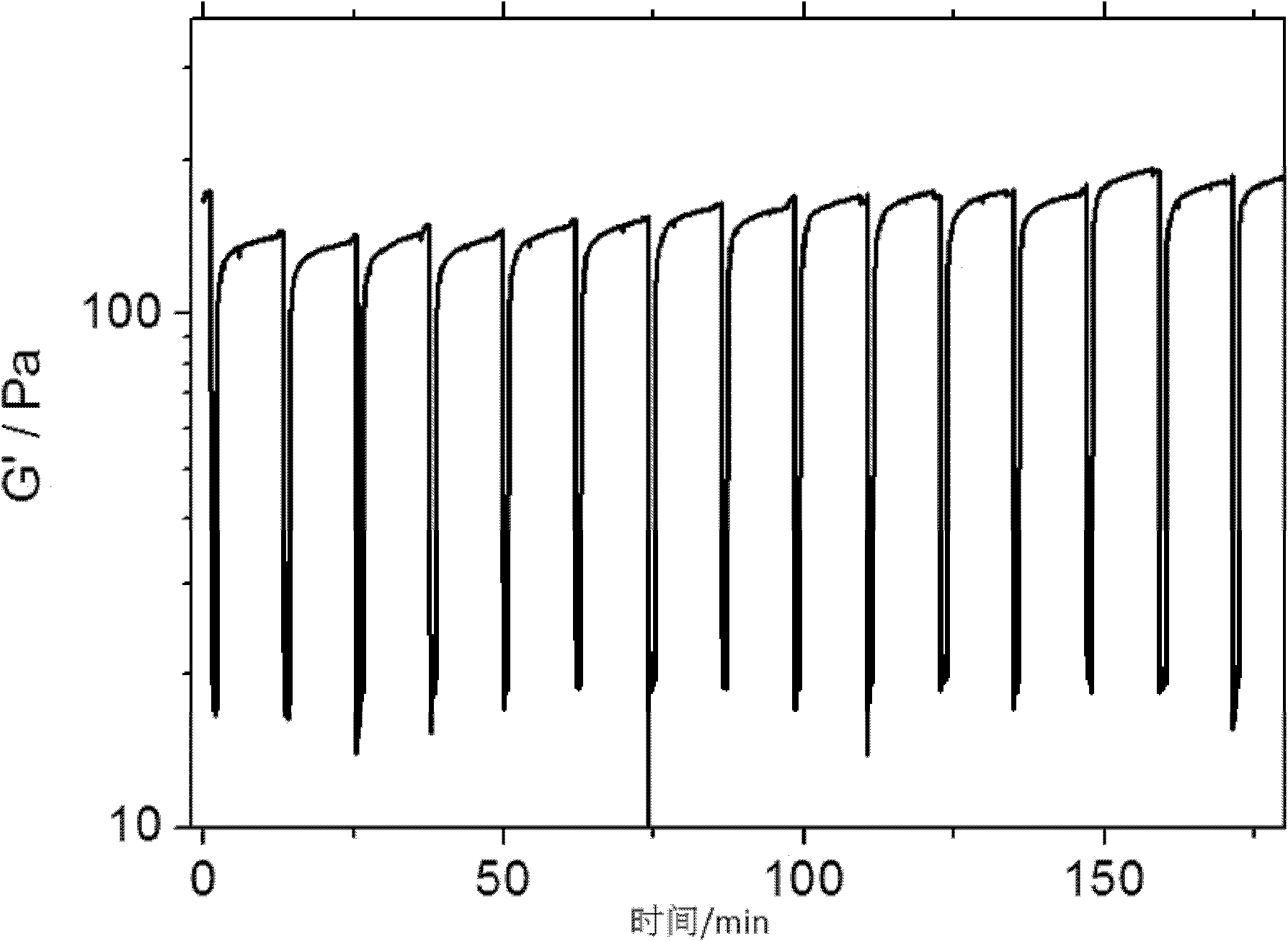

[0025] The above solution can be left to stand for 2 minutes to obtain a hydrogel material that can be injected into a gel. The inversion test proves that it is a solid state that does not flow; it is sucked into the syringe and then injected onto the surface of a vertically placed petri dish, and it instantly returns to a solid state. Hydrogel; the storage modulus is around 1000 Pascal; after more than 50 times of mechanical destruction and recovery experiments, its mechanical properties have no obvious change.

Embodiment 3

[0027] The concentration of sodium chloride added was 20 mM, and the rest of the experimental conditions were the same as in Example 1.

[0028] The above solution can be left to stand for 5 minutes to obtain a hydrogel material that can be injected into a gel. The inversion test proves that it is a solid state that does not flow; it is sucked into the syringe and injected onto the surface of a vertically placed petri dish, and it instantly returns to a solid state. Hydrogel; but the storage modulus of the gel is low, about 50 Pascals; after repeated mechanical damage 10 times, the storage modulus drops by about 30%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| storage modulus | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com