Controllable-phase strontium-doped calcium phosphate powder and preparing method thereof

A technology for strontium calcium phosphate and powder, which is applied in the field of controllable phase-doped strontium calcium phosphate powder and its preparation, can solve the problems of difficult control of two-phase components and proportions, appearance of impurity phases, and harsh sintering temperature control, and achieves Improves osteoinductive properties and bioactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

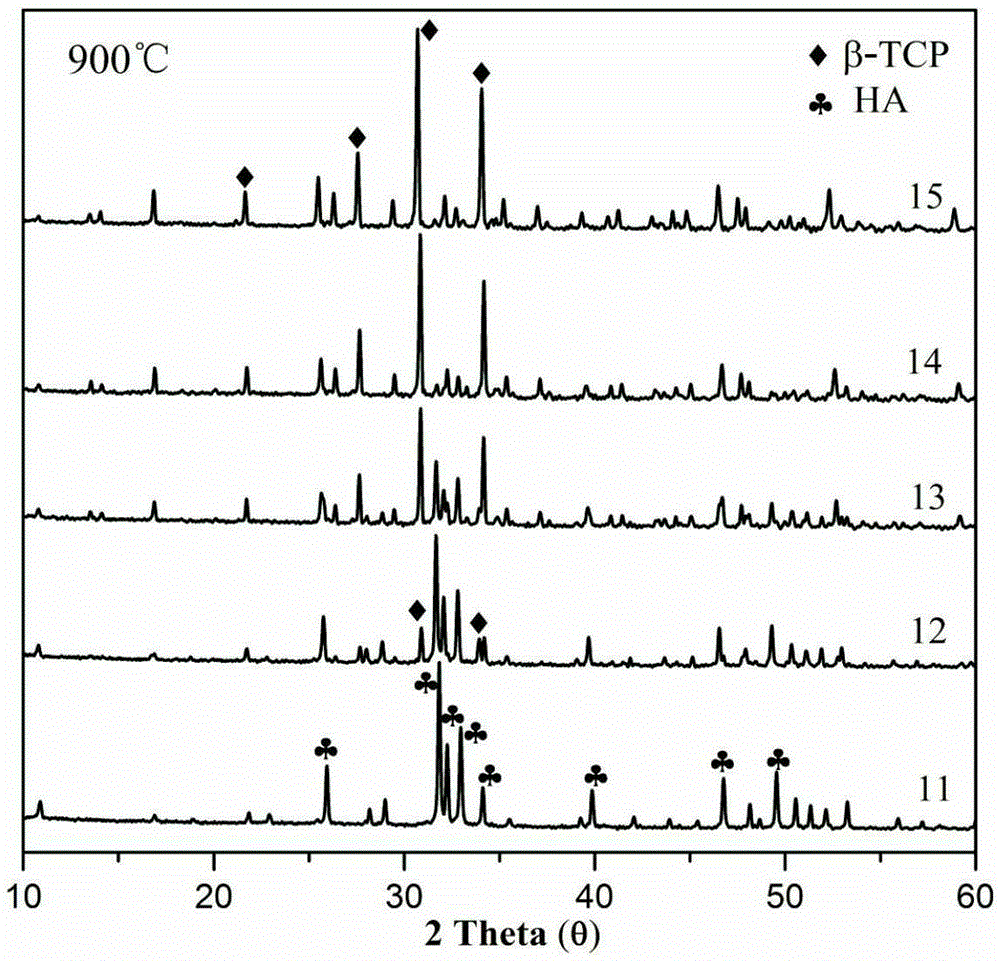

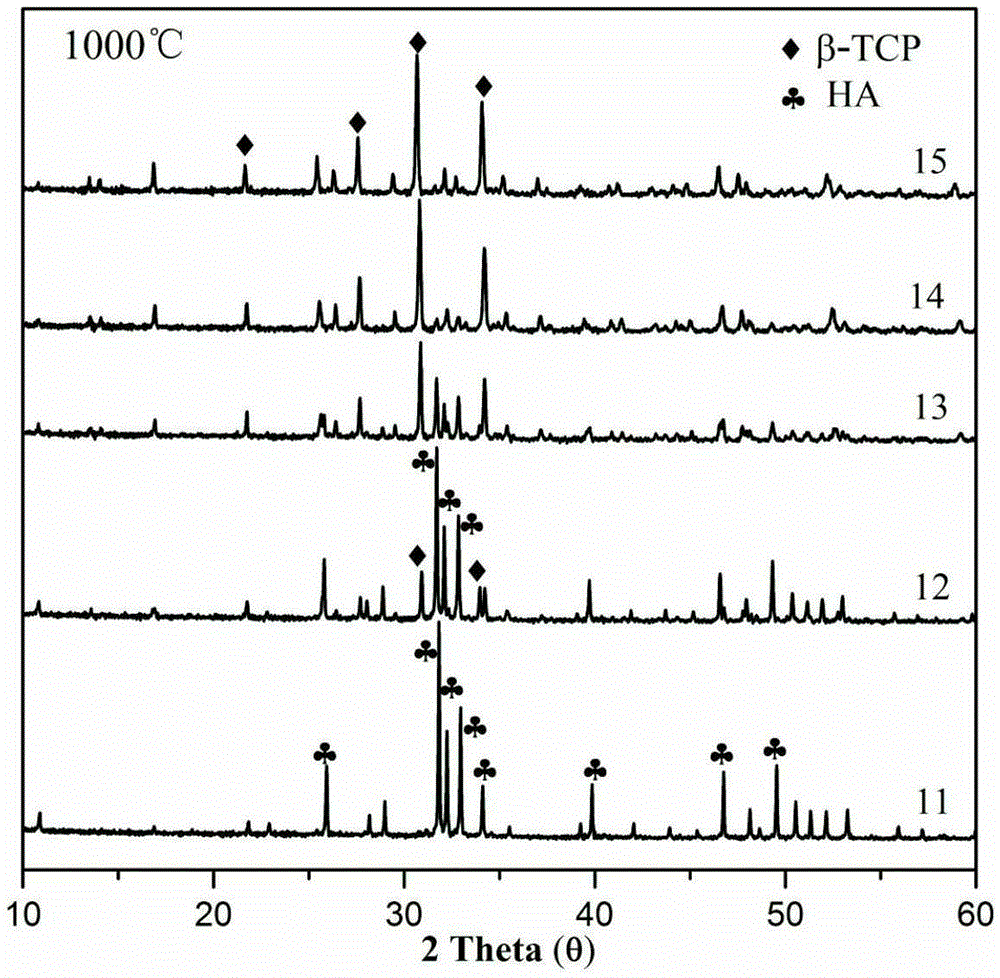

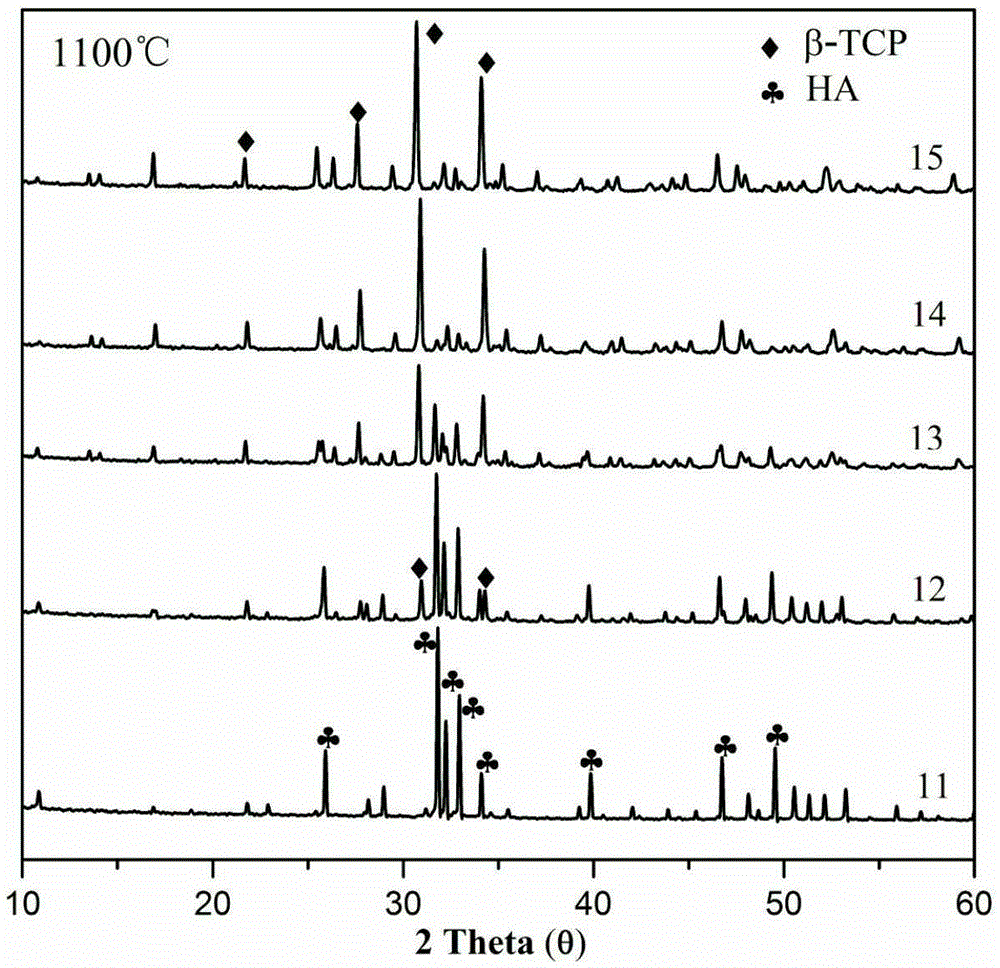

[0027] (1) Prepare 0.5mol / LCa(NO 3 ) 2 4H 2 O solution, 0.5mol / LSr(NO 3 ) 2 solution and 0.25mol / L (NH 4 ) 3 PO 4 ·3H 2 O solution, as calcium source, strontium source and phosphorus source. According to the molar ratio of (Ca+Sr) / P=1.67, a certain amount of Ca(NO 3 ) 2 4H 2 O and Sr(NO 3 ) 2 After the solution is mixed, use concentrated ammonia water to adjust the pH of the solution to be greater than 11. After vigorously stirring at 30°C, add polyethylene glycol (molecular weight: 6000) dispersant, and stir for 30 minutes to obtain a mixed solution containing calcium source and strontium source.

[0028] (2) At the same time adjust with concentrated ammonia water (NH 4 ) 3 PO 4 ·3H 2 The pH value of the O solution is greater than 10 to obtain a solution containing a phosphorus source; after controlling the dropping rate to 4mL / min with a peristaltic pump, slowly drop the solution containing a phosphorus source into the mixed solution containing a calcium sour...

Embodiment 2

[0036] (1) Prepare 0.5mol / LCa(NO 3 ) 2 4H 2 O solution, 0.5mol / LSr(NO 3 ) 2 solution and 0.25mol / L (NH 4 ) 3 PO 4 ·3H 2 O solution, as calcium source, strontium source and phosphorus source. According to the molar ratio of (Ca+Sr) / P=1.67, a certain amount of Ca(NO 3 ) 2 4H 2 O and Sr(NO 3 ) 2 After the solution is mixed, use concentrated ammonia water to adjust the pH of the solution to be greater than 11. After vigorously stirring at 30°C, add polyethylene glycol (molecular weight: 6000) dispersant, and stir for 30 minutes to obtain a mixed solution containing calcium source and strontium source.

[0037] (2) At the same time adjust with concentrated ammonia water (NH 4 ) 3 PO 4 ·3H 2 The pH value of the O solution is greater than 10 to obtain a solution containing a phosphorus source; after controlling the dropping rate to 4mL / min with a peristaltic pump, slowly drop the solution containing a phosphorus source into the mixed solution containing a calcium sour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com