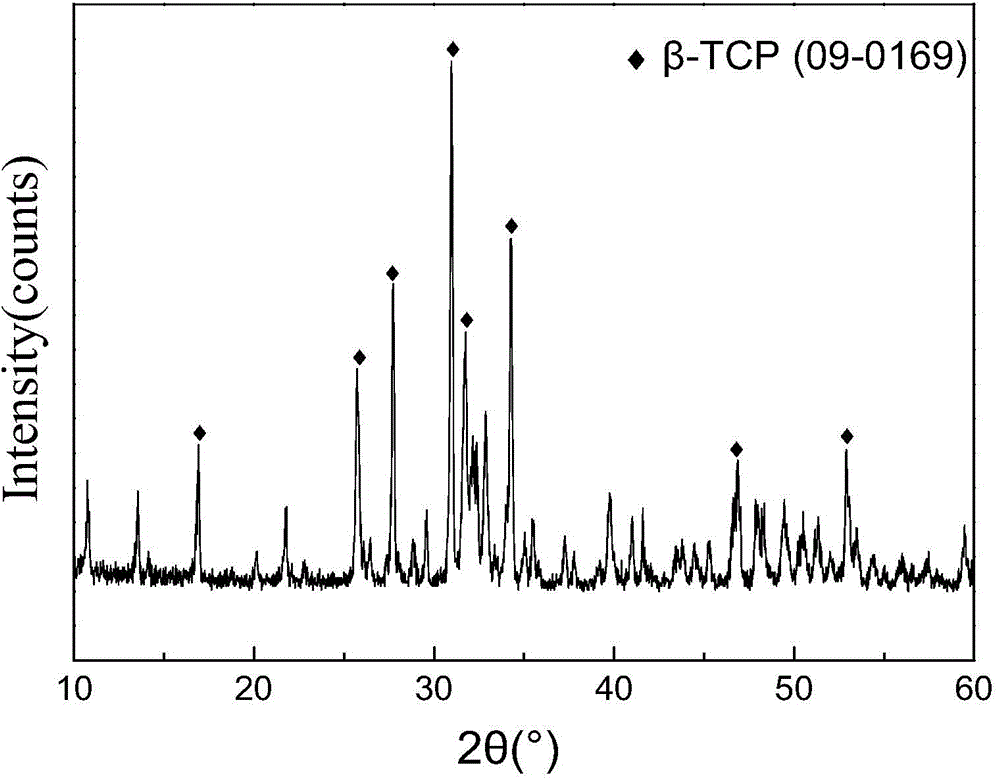

Preparation method of mesoporous beta-TCP (tricalcium phosphate) powder

A tricalcium phosphate powder and mesoporous technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of mesoporous β-TCP crystal habit and preparation difficulties, and achieve continuously adjustable pore size, high Effect of low specific surface area and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

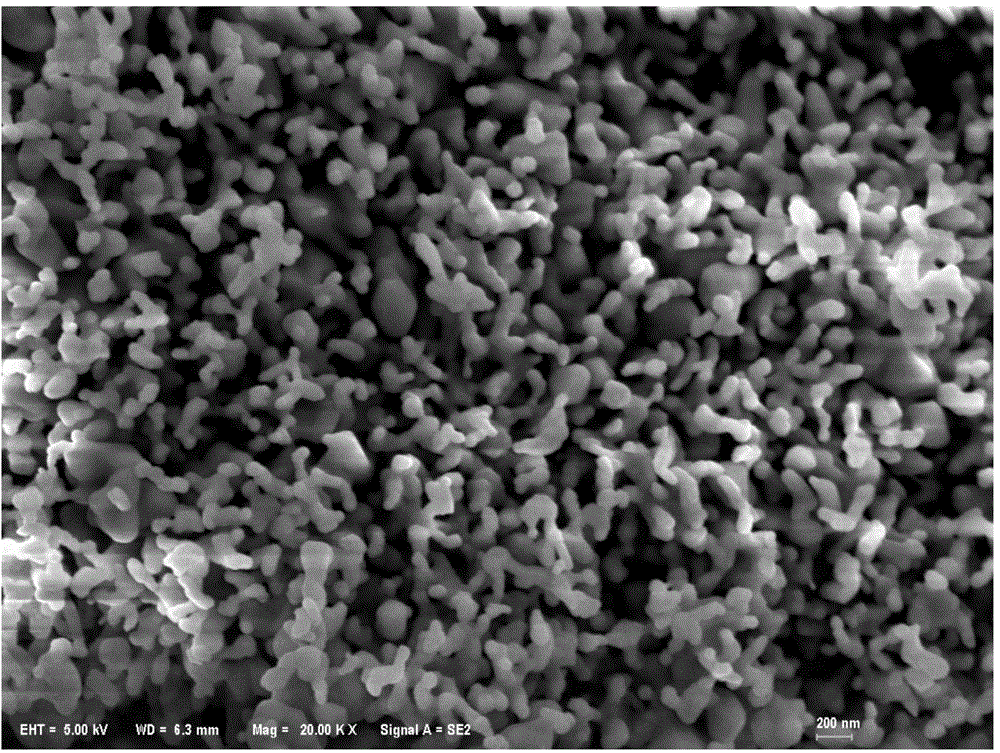

Embodiment 1

[0023] Prepare two transparent solutions containing surfactant CTAB, co-surfactant n-butanol and water, wherein the volume of water is 40 mL, the concentration of surfactant is 12.5 g / L, and the concentration of co-surfactant is 100 mL / L, and then to Add 0.5mol / L Ca(NO 3 ) 2 4H 2 O solution 20mL and 0.5mol / L (NH 4 ) 2 HPO 4 solution, and fully stirred at 40°C to obtain a mixed solution of calcium-containing inorganic salts and a mixed solution of phosphorus-containing inorganic salts. Keeping the temperature constant, add phosphorus-containing A mixed solution of inorganic salts, and the molar ratio of the added element calcium to phosphorus is 1.5:1, with NH 3 ·H 2 O solution to adjust the pH to 7.5, continue magnetic stirring for 21 hours, then stand at room temperature for 48 hours, centrifuge at 10,000 rpm for 3 minutes, wash the precipitate with water three times, then wash it with alcohol three times, and finally put the precipitate in a drying box After drying at...

Embodiment 2

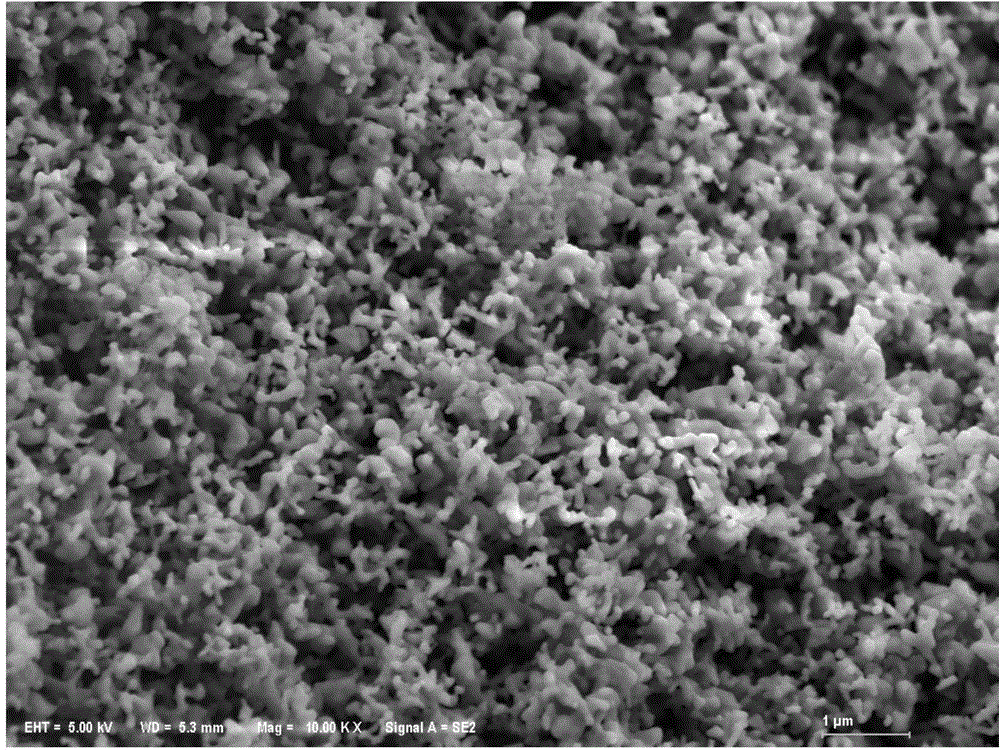

[0026] Prepare two clear solutions containing the surfactant polyethylene glycol 6000, the co-surfactant 1-octanol, and water, where the volume of water is 30 mL, the concentration of surfactant is 10 g / L, and the concentration of co-surfactant is 50 mL / L. L, then add 0.1mol / L CaCl to the two transparent solutions 2 Solution 30mL and 0.1mol / L NaH 2 PO 4solution, and fully stirred at 25°C to obtain a mixed solution of calcium-containing inorganic salts and a mixed solution of phosphorus-containing inorganic salts. Keep the temperature constant, add the mixed solution of phosphorus-containing inorganic salt to the mixed solution of calcium-containing inorganic salt at a speed of 0.2mL per minute, and make the molar ratio of the added element calcium to phosphorus be 1.5:1, and use NH 3 ·H 2 The pH of the O solution was adjusted to 6.0, and magnetic stirring was continued for 2 hours, then left to age at room temperature for 12 hours, centrifuged at 9500 rpm for 3 minutes, and...

Embodiment 3

[0028] Prepare two transparent solutions containing surfactant polyoxyethylene-polyoxypropylene-polyoxyethylene, co-surfactant n-propanol and water, wherein the volume of water is 200mL, the concentration of surfactant is 100g / L, co-surfactant The agent concentration was 250mL / L, and then 1.0mol / L of CaSO was added to the two transparent solutions 4 Solution 80mL and 1.0mol / L Na 3 PO 4 solution, and fully stirred at 90°C to obtain a mixed solution of calcium-containing inorganic salts and a mixed solution of phosphorus-containing inorganic salts. Keep the temperature constant, add the mixed solution of phosphorus-containing inorganic salt to the mixed solution of calcium-containing inorganic salt at a rate of 0.6mL per minute, and make the molar ratio of the added element calcium to phosphorus 1.5:1, use NH 3 ·H 2 The pH of the O solution was adjusted to 9.0, and the magnetic stirring was continued for 24 hours, then left to age at room temperature for 24 hours, centrifuged...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com