Biphase calcium phosphate (BCP) composite powder synthesized by high-temperature solid phase reaction and preparation method thereof

A high-temperature solid-state reaction, biphasic calcium phosphate technology, applied in prosthetics, medical science, tissue regeneration, etc., can solve the problem of inability to effectively control the grain size and crystallinity of HA and β-TCP, unsuitable for mass production, and pollution Low cost of raw materials, controllable grain size and crystallinity, and low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention also provides a method for preparing a biphasic calcium phosphate composite powder synthesized by a high-temperature solid-state reaction, comprising the following steps:

[0035] S1. Take the measured calcium-containing solid compound and calcium-phosphorus solid compound as raw materials, and the molar ratio of calcium to phosphorus Ca / P in the raw material is 1.5-1.67;

[0036] S2. Using wet ball milling, using ethanol and / or deionized water as the ball milling solvent, and using zirconia or aluminum oxide or tungsten carbide particles as the ball milling medium, the raw materials in step S1 are ball milled and mixed evenly;

[0037] S3. Take out the powder slurry uniformly mixed by ball milling in step S2, put it in a container to dry or put it in a constant temperature box to dry, and then pulverize it into uniform and fine mixed powder;

[0038] S4. Put the mixed powder obtained by crushing in step S3 into a corundum crucible and place it in ...

Embodiment 1

[0055] BCP (99wt% β-TCP+1wt% HA)

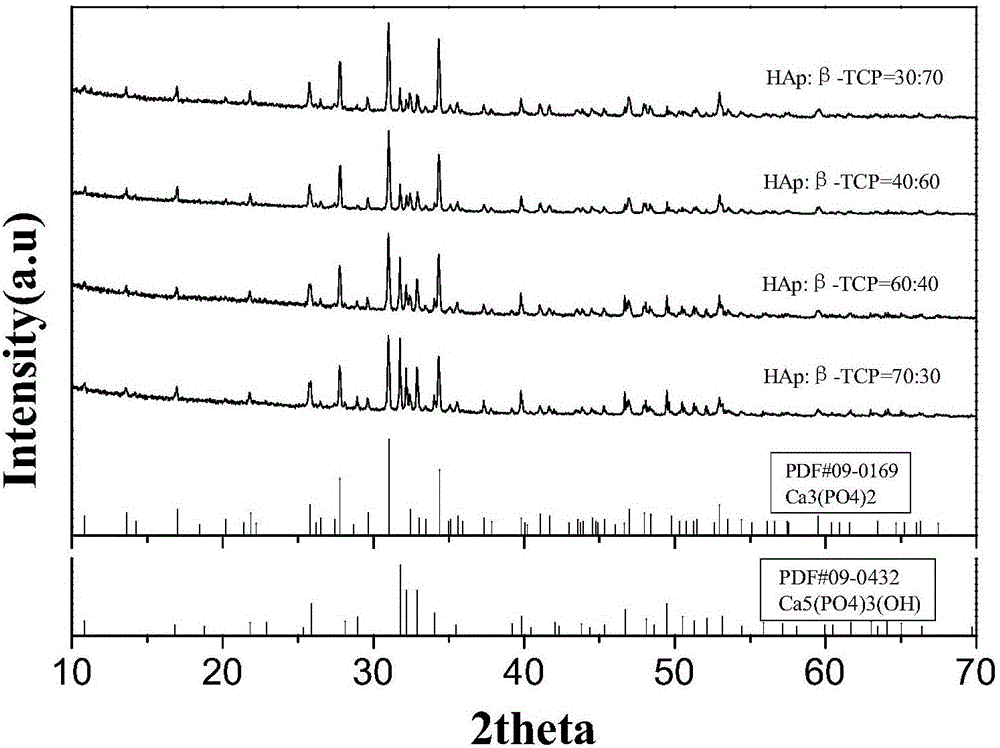

[0056] Weigh 200.78g of calcium carbonate and 688.36g of calcium hydrogen phosphate dihydrate, add 250ml of ethanol and ball mill for 25 hours, the mass ratio of raw materials and ball milling medium is 1:4, and the ball mill speed is 450rpm to obtain a uniformly mixed slurry, which is then dried and pulverized. Put the dried and pulverized mixed powder in a corundum crucible, and move it into a muffle furnace for calcination. When the temperature rises to 700°C, pour in deionized water at a rate of 0.2ml / min, and calcine at 900°C for 5 hours. The desired product was obtained after the furnace was cooled down. X-ray diffraction (XRD) and scanning electron microscope (SEM) analysis results showed that the product was BCP (99wt%β-TCP+1wt%HA) composite powder with a grain size of 0.1-2μm and a crystallinity of more than 75%.

Embodiment 2

[0058] BCP (1wt%β-TCP+99wt%HA)

[0059] Weigh 266.2g of calcium carbonate and 688.4g of calcium hydrogen phosphate dihydrate, the mass ratio of raw materials and ball milling medium is 1:4, add 500ml of deionized water and ball mill for 18 hours, the speed of the ball mill is 350rpm, obtain a uniformly mixed slurry, and then dry smash. Put the dried and pulverized mixed powder into the device for calcination. When the temperature rises to 700°C, deionized water is introduced at a rate of 1ml / min, and finally the temperature is raised to 1200°C and kept for 3 hours, and the temperature is lowered to 800°C at a rate of 5°C / min. After ℃, the deionized water was stopped, and the desired BCP (1wt% β-TCP+99wt% HA) composite powder was obtained after natural cooling. The results of XRD and SEM analysis show that the grain size of the product is 2-15 μm, and the crystallinity is above 85%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com