Design and manufacturing method of surface structure of parodontium-simulated dental implant

A technology of dental implants and surface structure, applied in the directions of additive manufacturing, dentistry, and dental implants, can solve the problems of stress concentration, insufficient osseointegration, and large differences in elastic modulus, so as to reduce local stress concentration and improve long-term stability. long-term success rate, and the effect of reducing the occurrence of inflammation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0019] The design and manufacture method of a kind of artificial periodontal ligament dental implant surface structure of the present invention has the following steps:

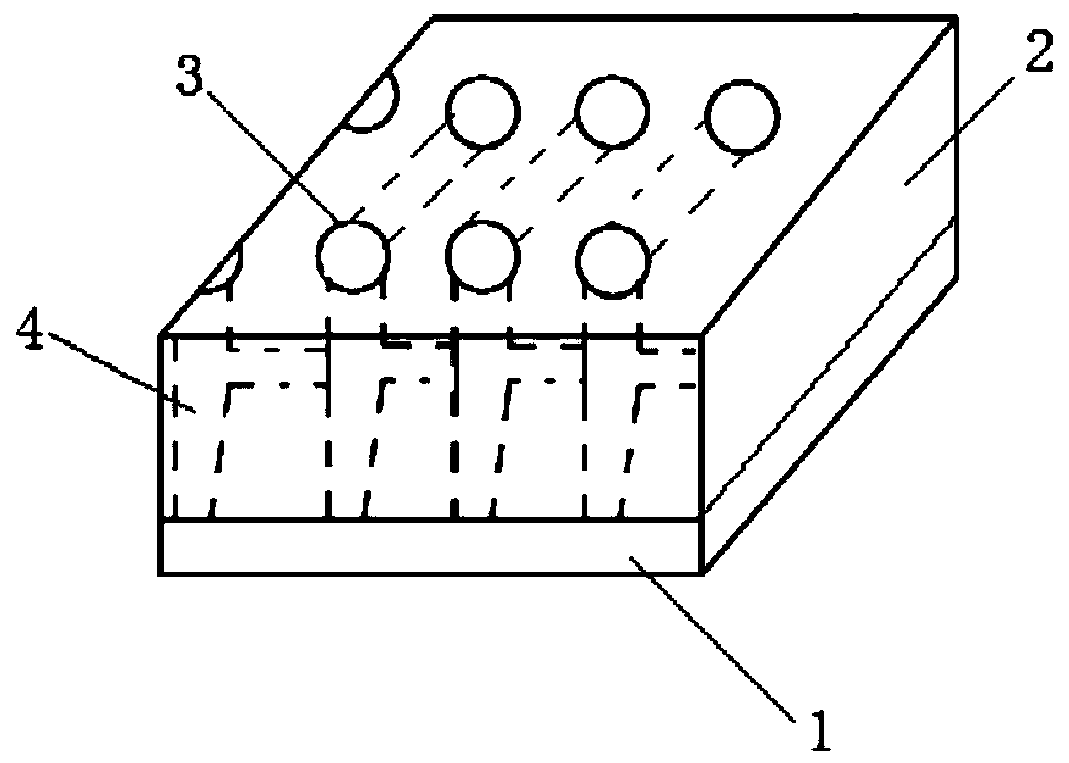

[0020] 1) The dental implant is divided into 2 layers, designed with CAD software and generated with 3D printing software to print files;

[0021] 2) The inner layer is a solid structure, and the thickness of the outer layer is about 0.1-0.5mm, which is a gradient hollow structure with a gradually increasing porosity from the inside to the outside;

[0022] 3) The porosity of the innermost layer of the hollow structure is 0, and the porosity of the outermost layer is 50-80%;

[0023] 4) The shape of the trabeculae in the pores and gaps is a bone-like trabecular structure, and the pores are cylindrical, conical or frustum-shaped, with a cross-sectional diameter of abo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com