Preparation method and uses of biodegradable high mechanical strength organic/inorganic composite hydrogel

An inorganic composite, hydrogel technology, applied in the field of biomedical composite materials, can solve the problems of lack of cell affinity and hydrophilicity, difficult to obtain hydrogel system, poor tissue compatibility, etc., to achieve improved mechanical properties, The effect of improving osteoinductive activity and osteogenic ability, and enhancing mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

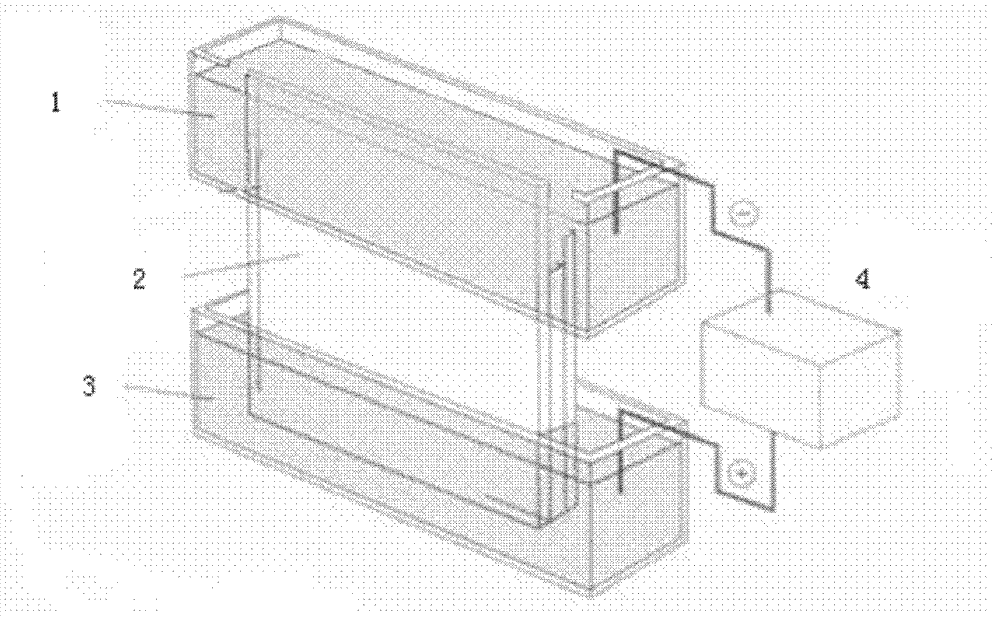

[0052] In the first embodiment of the preparation method of the present invention, step (1) preparation of peroxidized micellar polyacrylamide hydrogel includes the following sub-steps:

[0053] ① prepare polyoxyethylene-polyoxypropylene-polyoxyethylene block copolymer micellar aqueous solution, transfer it to a glass container, the container can be a large cylindrical glass test tube, under the condition of ventilation, pass the pre- Radiation methods, such as using 60 Co gamma-ray irradiation obtains a peroxidized surfactant solution, wherein the concentration of the aqueous solution of block copolymer micelles is preferably 5 to 15 g / L, also preferably 6 to 14 g / L, even more preferably 8 to 12 g / L L, most preferably 10g / L, described block copolymer can be EO for example 106 PO 70 EO 106 ;

[0054] ②Preparing acrylamide monomer or aqueous solution, it is preferably prepared into a solution of 3-10M, preferably 4-8M, more preferably 5-7M;

[0055] ③Mix the peroxidized su...

Embodiment 1

[0092] (1) Preparation of peroxidized micellar polyacrylamide hydrogel

[0093] ① Prepare 100mL of PF 127 aqueous solution with a concentration of 10g / L, transfer it to a large cylindrical glass test tube of 150mL, and use 60 Co gamma-ray irradiation for 8 hours, the irradiation dose rate was 2.5kGy / h, and a peroxidized surfactant solution was obtained;

[0094] ② Prepare 7M aqueous solution of acrylamide monomer solution;

[0095] ③Take 50mL of peroxidized surfactant solution and 100mL of monomer solution and mix evenly, take 12mL of the mixed solution and transfer it to a glass plate mold, place it in a vacuum desiccator, vacuumize the container and pass nitrogen gas into it, and cycle 3 times ;

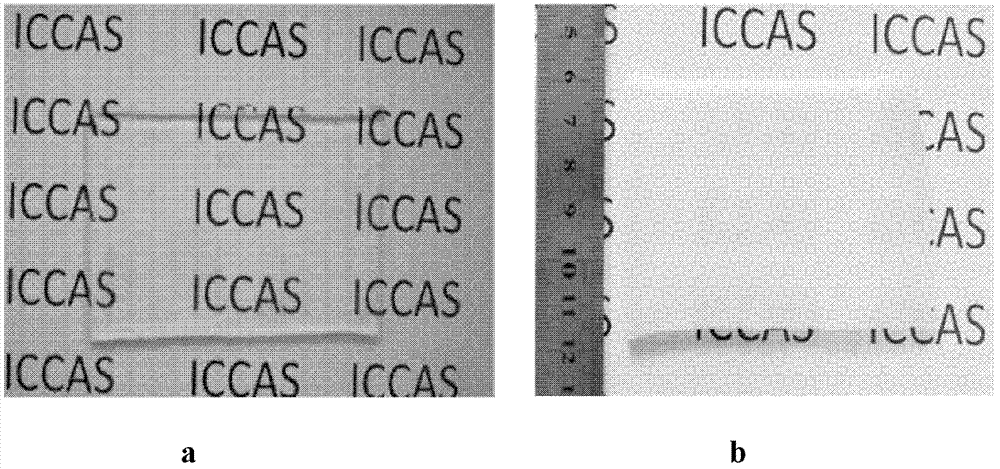

[0096] ④Place the reaction container in an environment of 50°C for reaction. The peroxide decomposes under heating conditions to generate free radicals, which initiates monomer polymerization. The reaction time is 36 hours, and a hydrogel is obtained. The appearance photos and ...

Embodiment 2

[0105] (1) Preparation of peroxidized micellar acrylamide hydrogel

[0106] ① Prepare 100mL of PF 127 aqueous solution with a concentration of 10g / L, transfer it to a large cylindrical glass test tube of 150mL, and use 60 Co gamma-ray irradiation for 8 hours, the irradiation dose rate was 2.5kGy / h, and a peroxidized surfactant solution was obtained;

[0107] ②Take 50mL of peroxidized surfactant solution to dissolve acrylamide monomer, add monomer and water to prepare 150mL of 6M acrylamide solution, transfer 12mL of the solution to a glass plate mold, and place it in a vacuum desiccator , after vacuumizing the container, nitrogen gas was introduced, and the cycle was repeated 3 times;

[0108] ③Put the reaction container in an environment of 50°C for reaction, the peroxide decomposes under heating conditions to generate free radicals, trigger monomer polymerization, and the reaction time is 36 hours to obtain a hydrogel.

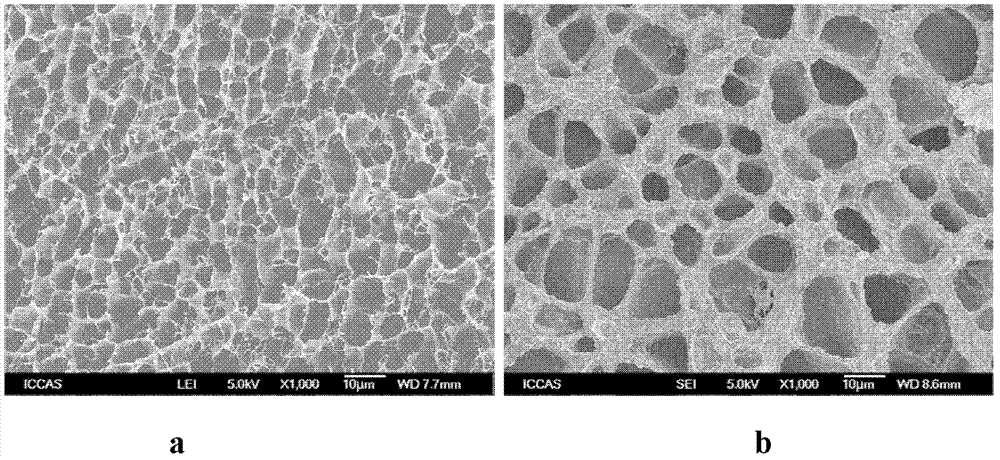

[0109] (2) Cycle freeze-thaw treatment of peroxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com