Double-photoresponse type zinc oxide, preparation method thereof and photosensitive coating with antibacterial osteogenesis

A photosensitive coating and photoresponsive technology, applied in zinc oxide/zinc hydroxide, coating, medical science, etc., can solve the problems of implant falling off, poor bonding of surrounding bone tissue, and no antibacterial performance, etc., and achieve good adsorption , antibacterial properties and good light and heat stability, the effect of improving antibacterial ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The invention provides a preparation method of dual-photoresponsive zinc oxide, comprising the following steps:

[0040] (1) Mix soluble zinc salt, hexamethylenetetramine and water for the first hydrothermal reaction, then mix the reaction feed liquid with sodium citrate, hydroxypropyl methylcellulose, photothermal conversion material and lignin Carrying out the second hydrothermal reaction to obtain a hydrothermal product;

[0041] (2) The hydrothermal product is subjected to freeze-drying and microwave irradiation in sequence to obtain a dual-photoresponsive zinc oxide.

[0042] Unless otherwise specified, the water used in the present invention is deionized water.

[0043] The present invention mixes soluble zinc salt, hexamethylenetetramine (HMT) and water to carry out the first hydrothermal reaction. In the present invention, the soluble zinc salt is preferably zinc nitrate, specifically zinc nitrate hexahydrate; the water is preferably deionized water; the tempe...

Embodiment 1

[0057] 50mmol (1.4875g) Zn (NO 3 ) 2 ·6H 2 O. 25 mmol (0.3505 g) of HMT was dissolved in 100 mL of deionized water, and stirred for 10 min under a sealed seal. After heating in a water bath at 65°C for 15min, add 0.14g Na 3 C 6 h 5 o 7 , 0.1g HPMC, 0.025g activated carbon and 0.1g lignin, keep the water bath at 85°C for 10h. Wash twice with absolute ethanol and twice with deionized water, all of which are centrifugally washed at a speed of 7000rpm, and the washing time is 15min, and then pre-frozen at -80°C and then vacuum freeze-dried for 12h, and the resulting product is subjected to microwave irradiation. The power of microwave irradiation is 800W, and the time is 15min to obtain double photoresponsive ZnO powder. Subsequent tests were carried out with the ZnO prepared in Example 1.

Embodiment 2

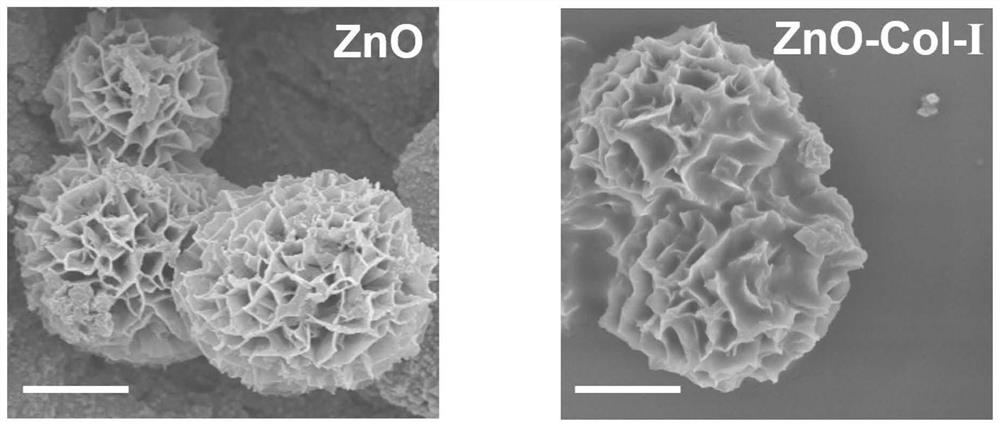

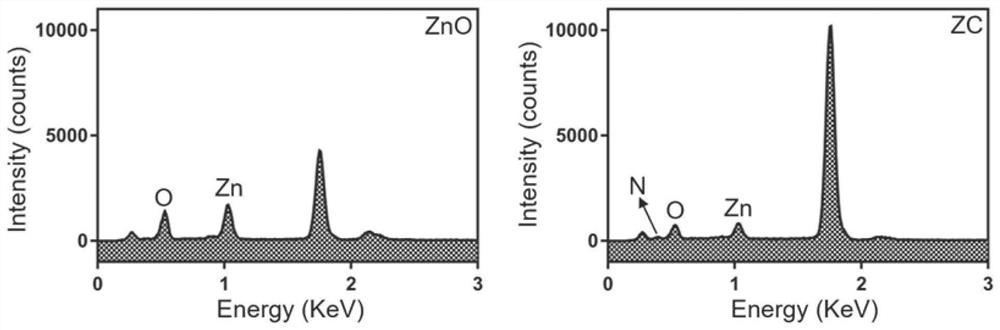

[0059] 1. Preparation of Ti-ZC: Add the ZnO powder and type I collagen powder prepared in Example 1 into phosphate-buffered saline solution (PBS buffer) according to the mass ratio of 1:1, and stir at 75rpm for 2h to obtain a suspension , the concentration of ZnO powder in the suspension is 200 μg / mL, the suspension is added dropwise on the surface of a titanium sample (a titanium sheet with a diameter of 10 mm and a thickness of 1 mm), dried at room temperature, and the coated titanium sample is designated as Ti-ZC.

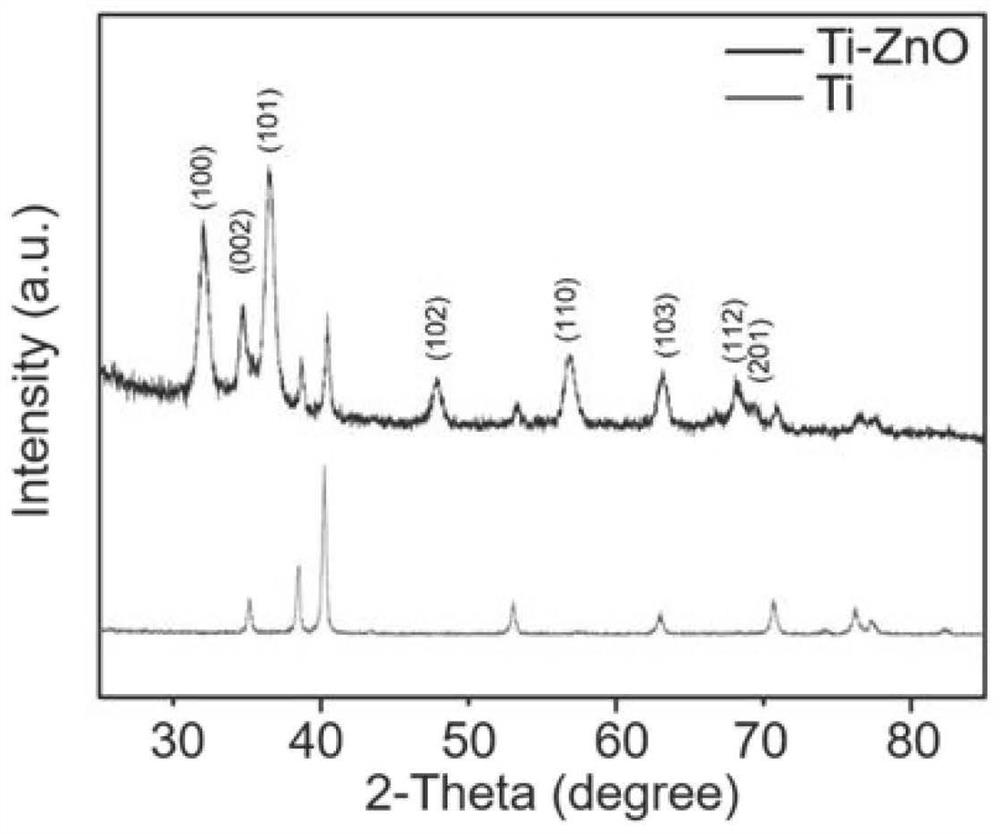

[0060] 2. Preparation of Ti-ZnO: Others are the same as in 1, except that type 1 collagen powder is not added, the concentration of ZnO in the suspension is 200 μg / mL, and the obtained sample is recorded as Ti-ZnO.

[0061] 3. Preparation of ZnO-Col-I: Using PBS buffer, mix ZnO and Col-I with the same concentration (200μg / ml) and shake in a shaker at a speed of 75-80rpm for 2-3 hours to prepare ZnO-Col-I. Col-I suspension, the obtained sample is recorded as ZnO-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com