Preparation method of nano antibacterial coating based on molybdenum disulfide and photosensitizer near-infrared optical response

A near-infrared photoresponse and antibacterial coating technology, which is applied in coatings, metal material coating technology, pharmaceutical formulations, etc., can solve the problem of poor biocompatibility of implants, no antibacterial effect, and aggravated secondary infections. problem, to achieve the effect of improving biocompatibility, making the preparation method simple and easy, and helping the body repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

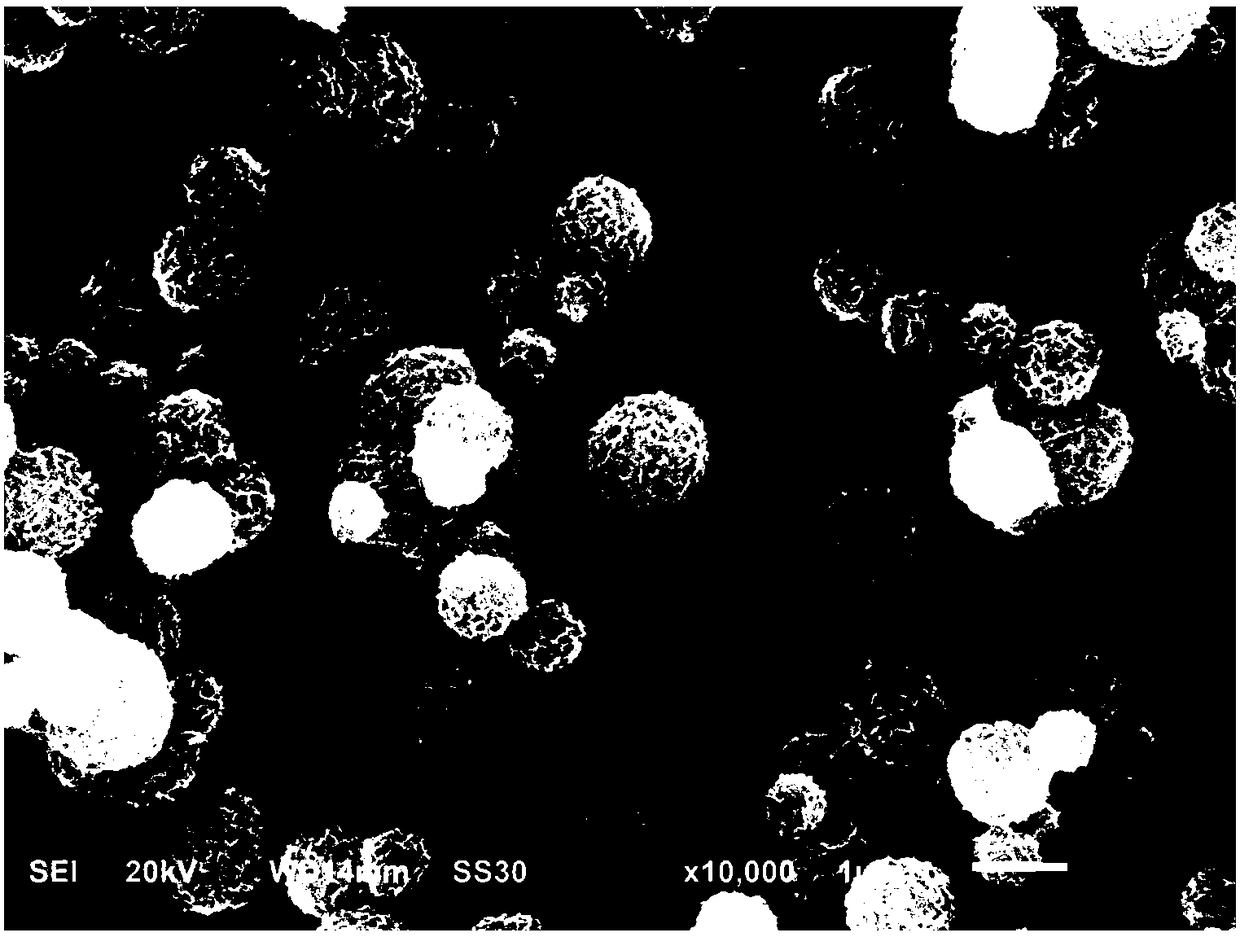

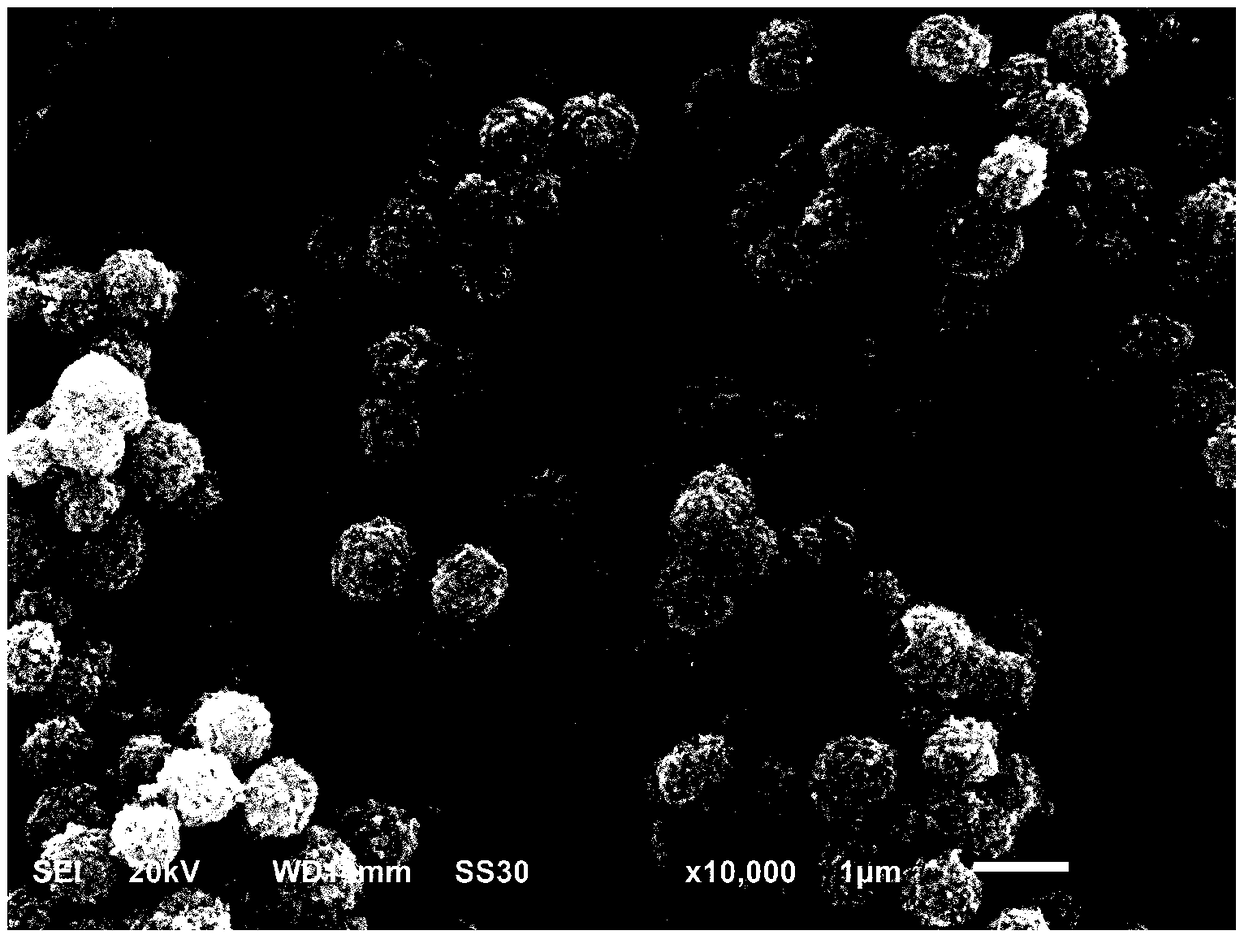

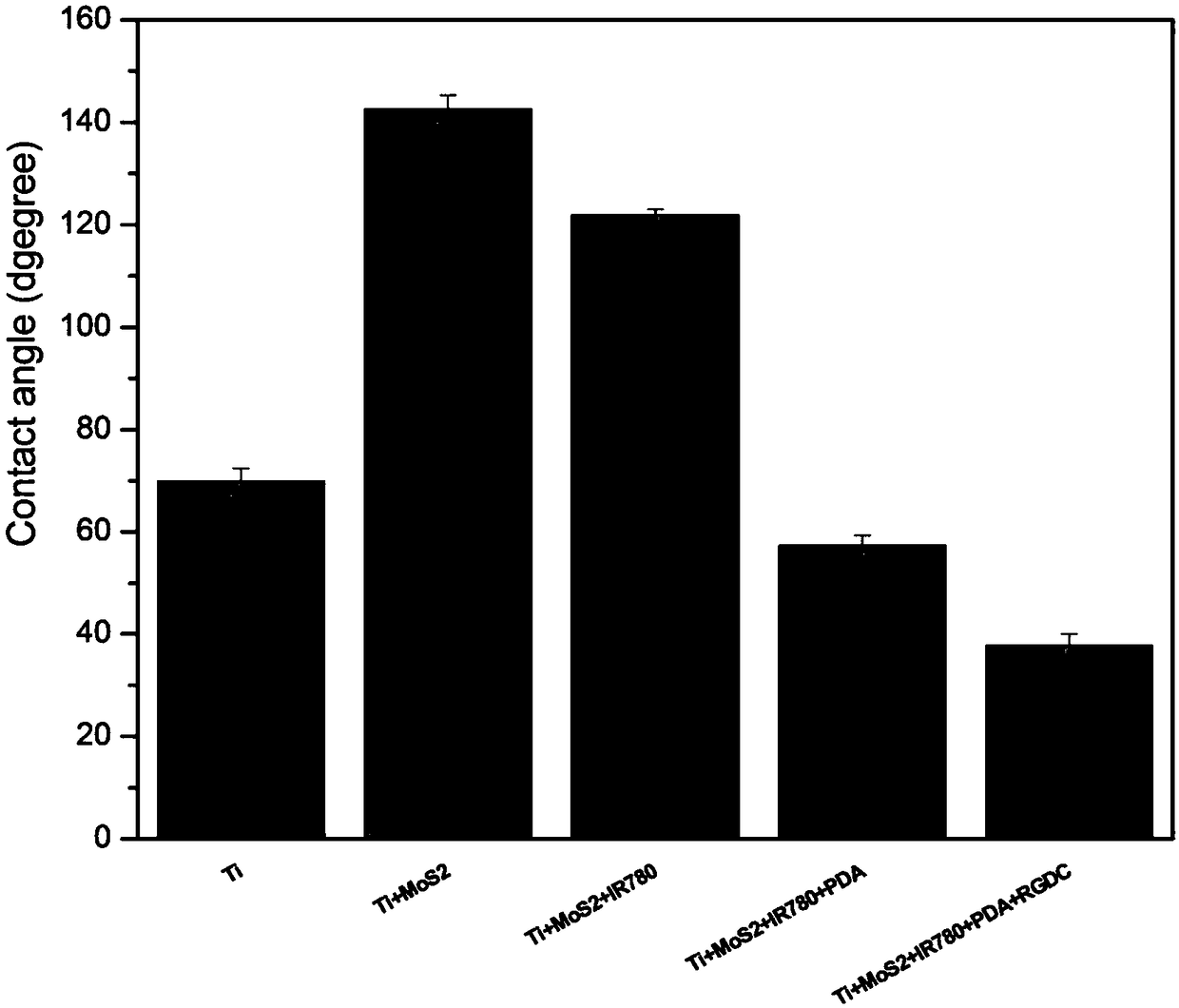

[0033] (1) Step 1: Grind the titanium alloy disc (diameter 6mm, thickness 2.5mm) step by step to 800 mesh with silicon carbide sandpaper, then ultrasonically clean it in ethanol and deionized water, dry and seal the cleaned titanium sheet for later use . Weigh 10mg of sodium molybdate dihydrate and 20mg of thioacetamide respectively and dissolve them in 20ml of deionized water. Stir continuously with a magnetic stirrer at medium speed for 30min to fully mix to obtain a clear and transparent liquid. Drain with a glass rod and transfer to a 100ml reaction kettle , Take out the previously saved titanium alloy discs and put them into the reactor one by one, so that the titanium alloy discs are evenly distributed at the bottom of the reactor, and then put the reactor into an oven to react at 200 ° C for 24 hours. After 24 hours, take out the titanium alloy disc in the reaction kettle, rinse it repeatedly with deionized water and absolute ethanol, and dry it in vacuum, then put the ...

Embodiment 2

[0037](1) Step 1: Grind the titanium alloy disc (diameter 6mm, thickness 2.5mm) step by step to 800 mesh with silicon carbide sandpaper, then ultrasonically clean it in ethanol and deionized water, dry and seal the cleaned titanium sheet for later use . Weigh 5mg of sodium molybdate dihydrate and 10mg of thioacetamide and dissolve them in 20ml of deionized water, stir continuously at medium speed with a magnetic stirrer for 30min to fully mix to obtain a clear and transparent liquid, drain it with a glass rod and transfer it to a 100ml reaction kettle , Take out the previously saved titanium alloy discs and put them into the reactor one by one, so that the titanium alloy discs are evenly distributed at the bottom of the reactor, and then put the reactor into an oven to react at 200 ° C for 24 hours. After 24 hours, take out the titanium alloy disc in the reaction kettle, rinse it repeatedly with deionized water and absolute ethanol, and dry it in vacuum, then put the dried sam...

Embodiment 3

[0041] (1) Step 1: Grind the titanium alloy disc (diameter 6mm, thickness 2.5mm) step by step to 800 mesh with silicon carbide sandpaper, then ultrasonically clean it in ethanol and deionized water, dry and seal the cleaned titanium sheet for later use . Weigh 20mg of sodium molybdate dihydrate and 40mg of thioacetamide respectively and dissolve them in 20ml of deionized water. Stir continuously with a magnetic stirrer at a medium speed for 30min to fully mix to obtain a clear and transparent liquid. Drain with a glass rod and transfer to a 100ml reaction kettle , Take out the previously saved titanium alloy discs and put them into the reactor one by one, so that the titanium alloy discs are evenly distributed at the bottom of the reactor, and then put the reactor into an oven to react at 200 ° C for 24 hours. After 24 hours, take out the titanium alloy disc in the reaction kettle, rinse it repeatedly with deionized water and absolute ethanol, and dry it in vacuum, then put th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com