Biomedical porous pure-titanium implant material and preparation method thereof

An implant material and biomedical technology, applied in the field of 3D printing, can solve the problems of inaccurate pore precision and complicated process, and achieve the effect of improving stability, simple process and accurate pore precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

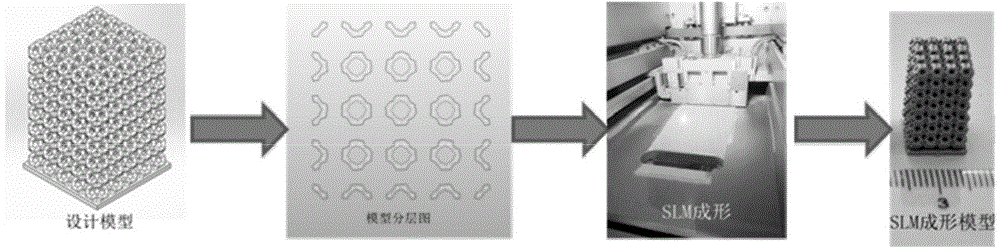

[0027] The biomedical porous pure titanium implant material of the present invention and its preparation method will be further described below in conjunction with the accompanying drawings and specific examples.

[0028] Selective Laser Melting technology (Selective Laser Melting) is an advanced additive manufacturing technology, it does not need a mold, through the principle of "layer-by-layer accumulation" of powder materials, completely melting each layer of powder, through the computer-aided design data model, quickly manufacture Precise and controllable fabrication of complex 3D solid models.

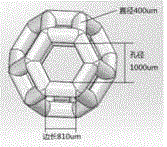

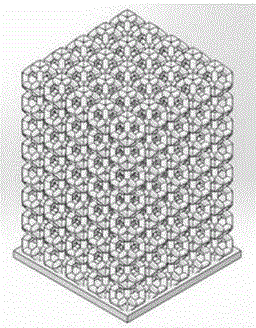

[0029] see figure 1 , figure 2 and image 3 , the invention discloses a preparation method of a biomedical porous pure titanium implant material, comprising the following steps:

[0030] S1. Use drawing software to build a three-dimensional model of the implanted material, and slice it through layering software, save the obtained two-dimensional section information in SLM form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Side length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com