Method of preparing TiSrO3 coating on surface of titanium implant

A titanium implant and coating technology, applied in the field of bioactive artificial tooth root implants, can solve the problem that the material does not have the function of promoting or inducing osteogenesis, and achieves the effect of easy operation and improved specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

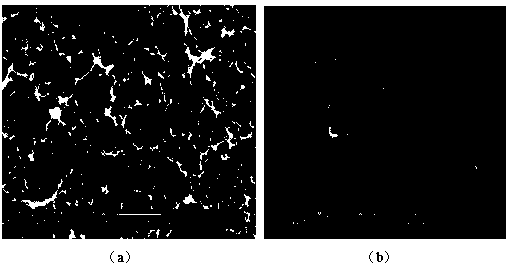

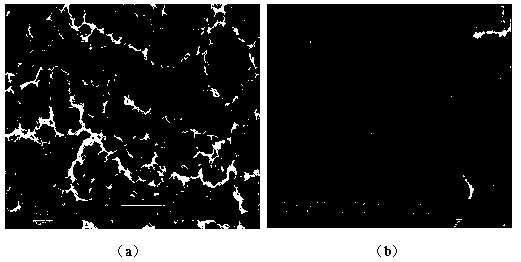

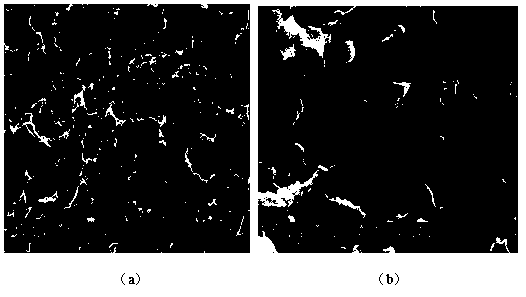

Image

Examples

Embodiment 1

[0026] A preparation of TiSrO on the surface of titanium implant 3 The coating method is characterized in that it comprises the following steps:

[0027] (1) Titanium implant pretreatment: The surface of the titanium implant was sandblasted with emery, the pressure was 4 bar, and then placed in acetone, ethanol with a volume percentage of 75%, and distilled water for ultrasonic cleaning, and dried; 2.75M HF and 3.94M HNO 3 The mixed aqueous solution was treated for 2min, rinsed with double distilled water, and dried; then with 18wt% HCl and 48wt%H 2 SO 4 The mixed aqueous solution was treated at 80°C for 30 minutes, rinsed with double distilled water, and dried;

[0028] (2) Preparation of hydrothermal solution:

[0029] Sr(OH) 2 Solution preparation: distilled water as solvent, Sr(OH) 2 ·8H 2 O is the solute, prepare 0.02MSr(OH) 2 solution;

[0030] (3) Put the titanium implant pretreated in step 1 into a hydrothermal reaction kettle containing the Sr(OH) prepared in...

Embodiment 2

[0033] A preparation of TiSrO on the surface of titanium implant 3 The coating method is characterized in that it comprises the following steps:

[0034] (1) Titanium implant pretreatment: The surface of the titanium implant was sandblasted with emery, the pressure was 4 bar, and then placed in acetone, ethanol with a volume percentage of 75%, and distilled water for ultrasonic cleaning, and dried; with 2.75M HF and 3.94M HNO 3 The mixed aqueous solution was treated for 2min, rinsed with double distilled water, and dried; then with 18wt% HCl and 48wt%H 2 SO 4 The mixed aqueous solution was treated at 80°C for 30 minutes, rinsed with double distilled water, and dried;

[0035] (2) Preparation of hydrothermal solution:

[0036] SrCl 2 Solution preparation: distilled water as solvent, CaCl 2 , (NH 4 ) 2 h 2 PO4 , SrCl 2 ·6H 2 O is the solute, where CaCl 2 The concentration is 3.6×10 ?4 M, SrCl 2 ·6H 2 The concentration of O is 1.9×10 ?5 M, CaCl 2 and SrCl 2 ·6H...

Embodiment 3

[0040] A preparation of TiSrO on the surface of titanium implant 3 The coating method is characterized in that it comprises the following steps:

[0041] (1) Titanium implant pretreatment: The surface of the titanium implant was sandblasted with emery, the pressure was 4 bar, and then placed in acetone, ethanol with a volume percentage of 75%, and distilled water for ultrasonic cleaning, and dried; 2.75M HF and 3.94M HNO 3 The mixed aqueous solution was treated for 2min, rinsed with double distilled water, and dried; then with 18wt% HCl and 48wt%H 2 SO 4 The mixed aqueous solution was treated at 80°C for 30 minutes, rinsed with double distilled water, and dried;

[0042] (2) Preparation of hydrothermal solution:

[0043] Sr(OH) 2 Solution preparation: distilled water as solvent, Sr(OH) 2 ·8H 2 O is the solute, prepare 0.03M Sr(OH) 2 solution;

[0044] (3) Put the titanium implant pretreated in step 1 into a hydrothermal reaction kettle containing the Sr(OH) prepared i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com