Process of forming fluoric stepped hole structure on the surface of pure titanium dental implant

A dental implant and pure titanium technology, which is applied in the field of preparing fluorine-containing multi-level pore structure, can solve the problems of negative impact on the long-term stability of implants, and achieve the effect of improving long-term clinical success rate and good bone tissue compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] (1) The surface of the pure titanium dental implant is sandblasted with large particles (0.25~1.5mm) of green silicon carbide, and the pressure is 4bar, so that the surface forms an irregular rough surface with ups and downs, that is, micron-sized pits, with a diameter of 10~ 30 μm; place in acetone, 75% ethanol and distilled water for ultrasonic cleaning, and dry;

[0016] (2) With 5.60mol / L HCl and 8.70mol / L H 2 SO 4 The mixed solution was treated at 70°C for 40 minutes, rinsed with double distilled water, and dried to form submicron-scale small pits on the surface on the basis of large pits, with a diameter of 0.2-3 μm.

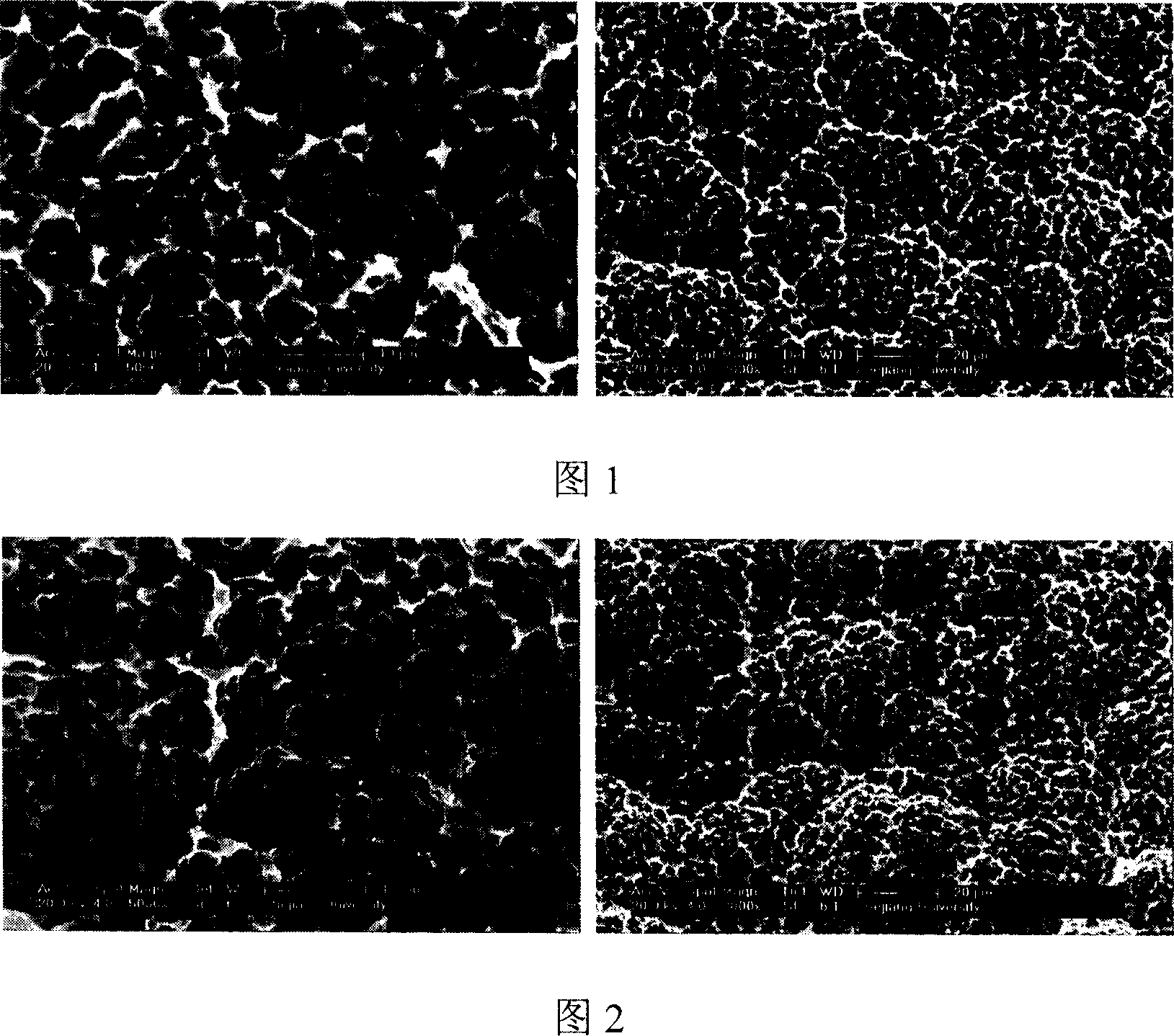

[0017] (3) Use 0.055mol / L HF and 0.07mol / L HNO again 3 The formed mixed solution was treated for 15 minutes, rinsed with double distilled water, and dried to obtain a surface with a fluorine-containing multi-level pore structure (as shown in Figure 1, the left figure is 5000 times, the right figure is 2000 times), and the fluorine content is betwe...

Embodiment 2

[0019] (1) The surface of the titanium dental implant is sandblasted with large particles (0.25-1.5 mm) of green silicon carbide, and the pressure is 4 bar, so that the surface forms an irregular rough surface with ups and downs, that is, micron-sized pits, with a diameter of 10-30 μm ; Then place in acetone, 75% ethanol and distilled water for ultrasonic cleaning, and dry;

[0020] (2) With 5.80mol / L HCl and 9.00mol / L H 2 SO 4 The mixed solution was treated at 80°C for 30 minutes, rinsed with double distilled water, and dried to form small submicron pits on the surface on the basis of large pits, with a diameter of 0.2 to 3 μm.

[0021] (3) Use 0.055mol / L HF and 0.09mol / L HNO again 3 The formed mixed solution is treated for 10 minutes, rinsed with double distilled water, and dried to obtain a surface with a fluorine-containing multi-level hole structure, and the fluorine content is between 1.5 at% and 5 at%.

[0022] (4) Soak in 4% sodium fluoride solution for 1 hour at la...

Embodiment 3

[0024] (1) The surface of the titanium dental implant is sandblasted with large particles (0.25-1.5 mm) of green silicon carbide, and the pressure is 4 bar, so that the surface forms an irregular rough surface with ups and downs, that is, micron-sized pits, with a diameter of 10-30 μm ; Then place in acetone, 75% ethanol and distilled water for ultrasonic cleaning, and dry;

[0025] (2) With 6.00mol / L HCl and 9.20mol / L HCl 2 SO 4 The mixed solution was treated at 90°C for 20 minutes, rinsed with double distilled water, and dried to form small submicron pits on the surface on the basis of large pits, with a diameter of 0.2 to 3 μm.

[0026] (3) Use 0.11mol / L HF and 0.11mol / L HNO again 3 The formed mixed liquid is treated for 5 minutes, rinsed with double distilled water, and dried to obtain a surface with a fluorine-containing multi-level hole structure, and the fluorine content is between 1.5 at% and 5 at%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com