Application and preparation method of alkaline coating on surface of dental zirconia ceramic

A technology of zirconia ceramics and zirconia hydroxide, applied in dental preparations, dentistry, dental prosthesis, etc., to achieve the effects of enhancing hydrolysis resistance, improving bonding strength, and improving bonding hydrolysis resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

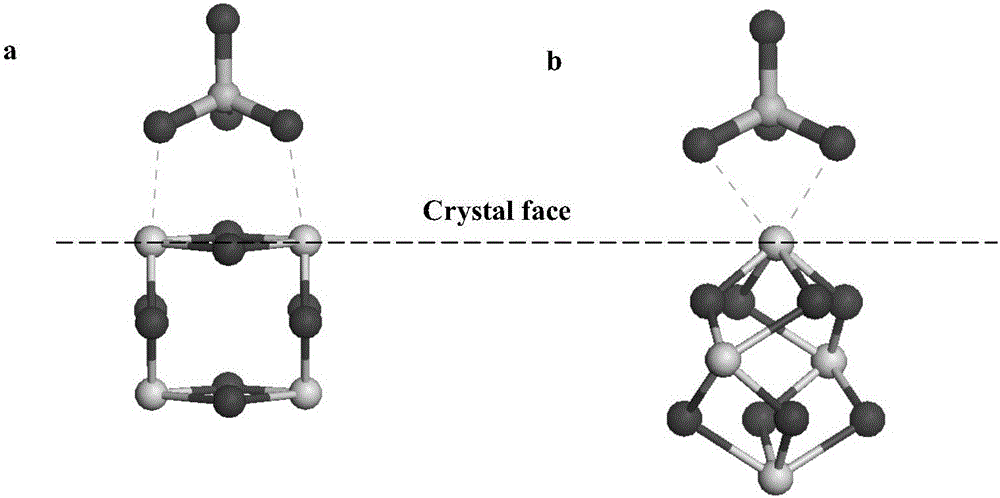

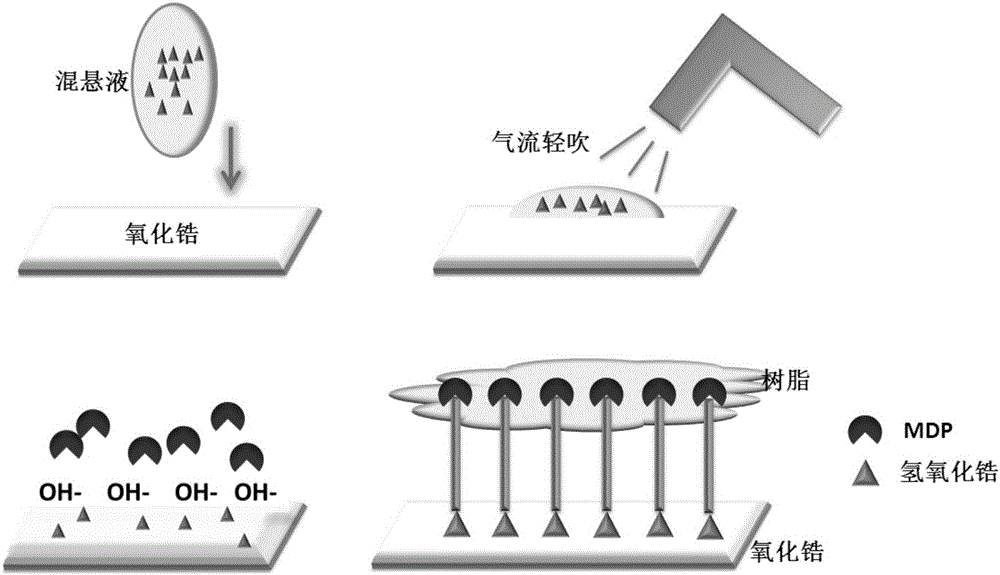

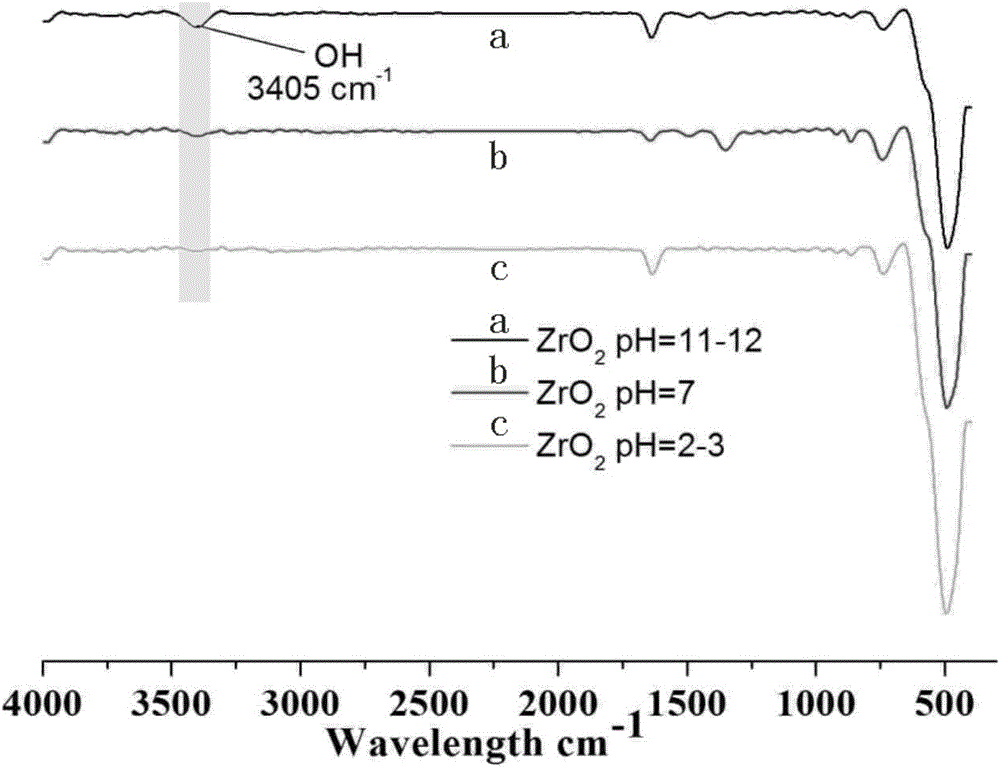

[0027] The coating of the present invention uses nanometer zirconium hydroxide as the main component, is prepared by a nanometer zirconium hydroxide suspension dropping method or brushing method, and is formed after a certain heat treatment procedure. Before treating dental zirconia ceramic restorations with ceramic primers containing phosphate monomer MDP that are currently on the market, first use one of the following options:

[0028] Option 1, use the prepared lye to treat the ceramic bonding surface. The lye is a suspension with a pH value between 10-14. Its components are sodium carbonate, sodium bicarbonate, and sodium hydroxide aqueous solution Any one of them is mixed with 5-10wt% zirconium hydroxide. Shake well before use, drop it on the ceramic surface, let it evaporate naturally for 1-3 minutes and then blow dry.

[0029] Option 2, configure 10-20wt% zirconium hydroxide aqueous suspension, the pH value can be between 10-14, shake well before use, apply the zirconi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com