Surface mount method of mineralized collagen gradient coating for medical titanium implant

A technology of mineralized collagen and gradient coating, which is applied in the direction of electrolytic inorganic material coating, etc., can solve the problems of coating shedding, low bonding strength, and inability to play the role of coating, so as to achieve uniform coating distribution and accelerate early healing speed , good biocompatibility and bioresponsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

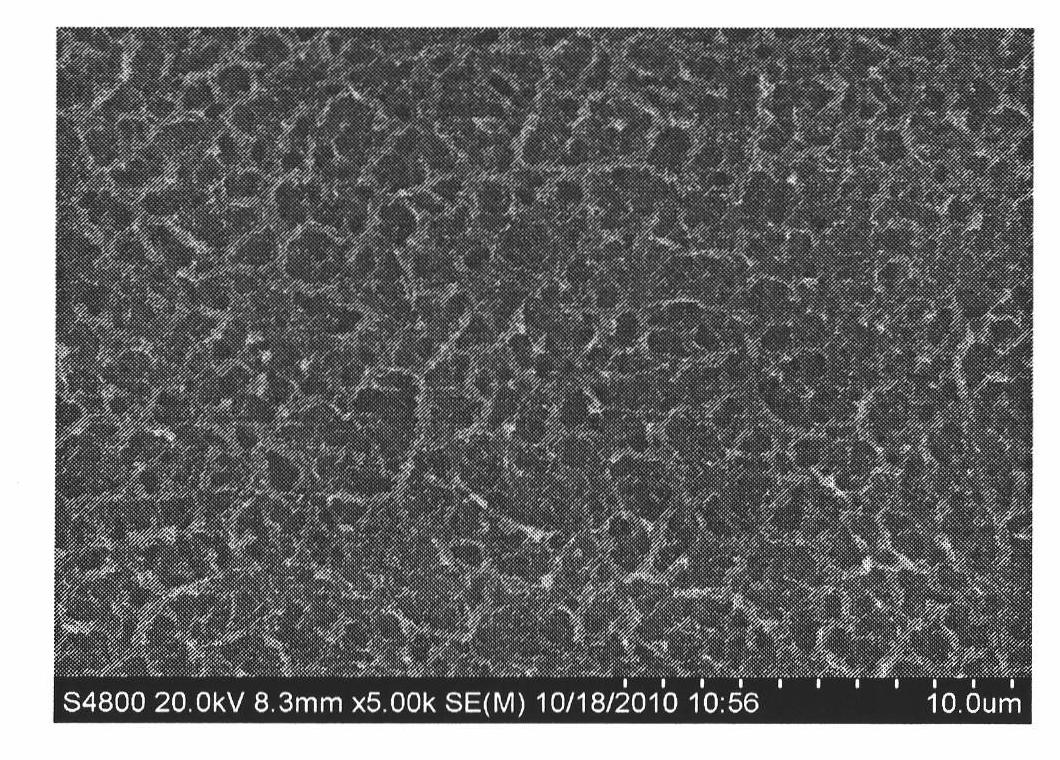

[0026] 1) The titanium substrate was ultrasonically cleaned in water and ethanol in sequence, and then cleaned with HF and HNO 3 The mixed acid solution corrosion, the concentration of HF in the mixed acid solution is 2.7M, HNO 3 The concentration is 3.9M, corroded for 2 minutes, and then kept in a 5M NaOH solution at 50°C for 24 hours, taken out and ultrasonically cleaned with a 1M HCl solution for 3 minutes, and finally heat-treated at 600°C for 2 hours to obtain Titanium substrate with a porous oxide layer on the surface (see figure 1 );

[0027] 2) Calcium nitrate is dissolved in water to prepare a calcium-containing aqueous solution with a calcium concentration of 40 mM, and ammonium dihydrogen phosphate is dissolved in water to prepare a phosphorus-containing aqueous solution with a phosphorus concentration of 80 mM, and the calcium-containing aqueous solution and the phosphorus-containing aqueous solution are stirred and mixed , to obtain A solution;

[0028] 3) Diss...

Embodiment 2

[0034] 1) The titanium substrate was ultrasonically cleaned in water and ethanol in sequence, and then cleaned with HF and HNO 3 The mixed acid solution corrosion, the concentration of HF in the mixed acid solution is 2.2M, HNO 3The concentration is 4.1M, corroded for 3 minutes, and then kept in a 5M NaOH solution at 50°C for 24 hours, taken out and ultrasonically cleaned with a 1M HCl solution for 2 minutes, and finally heat-treated at 600°C for 2 hours to obtain A titanium substrate with a porous oxide layer on the surface;

[0035] 2) Dissolve calcium chloride in water to prepare a calcium-containing aqueous solution with a calcium concentration of 60 mM, dissolve sodium dihydrogen phosphate in water to prepare a phosphorus-containing aqueous solution with a phosphorus concentration of 120 mM, and stir the calcium-containing aqueous solution and the phosphorus-containing aqueous solution Mix to obtain A solution;

[0036] 3) Dissolving the collagen in an acetic acid solut...

Embodiment 3

[0042] 1) The titanium substrate was ultrasonically cleaned in water and ethanol in sequence, and then cleaned with HF and HNO 3 The mixed acid solution corrosion, the concentration of HF in the mixed acid solution is 2.5M, HNO 3 The concentration is 4.5M, corroded for 2 minutes, and then kept in a 5M NaOH solution at 50°C for 24 hours, taken out and ultrasonically cleaned with a 1M HCl solution for 5 minutes, and finally heat-treated at 600°C for 2 hours to obtain A titanium substrate with a porous oxide layer on the surface;

[0043] 2) Calcium nitrate is dissolved in water to prepare a calcium-containing aqueous solution with a calcium concentration of 80 mM, and ammonium dihydrogen phosphate is dissolved in water to prepare a phosphorus-containing aqueous solution with a phosphorus concentration of 160 mM, and the calcium-containing aqueous solution and the phosphorus-containing aqueous solution are stirred and mixed , to obtain A solution;

[0044] 3) Dissolving the col...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com