Double-thermometer linkage control technology

A technology of linkage control and temperature meter, applied in the field of tobacco processing, can solve problems such as affecting the accuracy and stability of temperature control of equipment, and distorted detection temperature, so as to improve the production control level of cigarettes, improve the control level, and improve the stability of temperature control. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

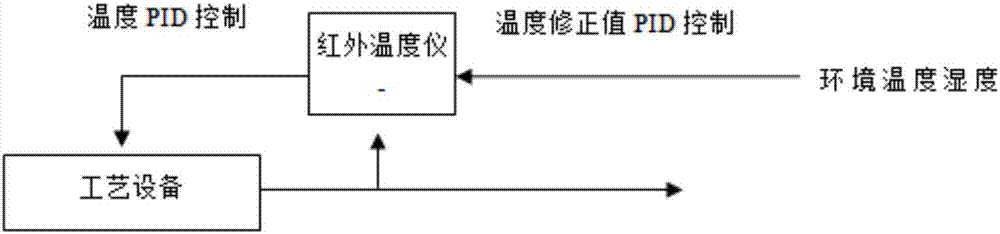

[0031] A dual temperature instrument linkage control technology, such as figure 1 As shown, the ambient temperature and humidity are detected, and the influence of the ambient temperature and humidity on the temperature of the material detected by the online infrared temperature instrument is formed into a mathematical correction model. Consistent, can control material temperature more accurately and stably, and stabilize product quality.

[0032] Further, the implementation steps of detecting the ambient temperature and humidity are as follows:

[0033] S11. Install and inspect the online infrared thermometer, select the most representative location for the ambient temperature and humidity from the passage of the material and install the ambient temperature and humidity detector. The installation position of the ambient temperature and humidity detector is usually at the same level as the material, in the middle of the material outlet to the installation point of the infrare...

Embodiment 2

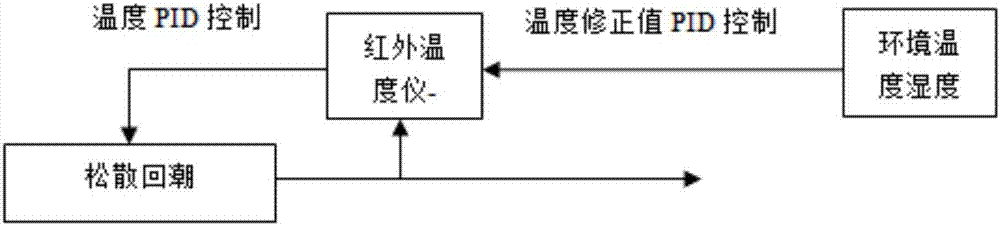

[0048] like figure 2 As shown, it is a principle diagram when the present invention is applied to the loosening and dampening link of the silk thread. Detect the ambient temperature and humidity, and form a mathematical correction model based on the influence of the ambient temperature and humidity on the temperature of the material detected by the online infrared temperature instrument. More accurate and stable control of material temperature, stable product quality.

[0049] Further, the implementation steps of detecting the ambient temperature and humidity are as follows:

[0050] S11. Install and inspect the online infrared thermometer, select the most representative location for the ambient temperature and humidity from the passage of the material and install the ambient temperature and humidity detector. The installation position of the ambient temperature and humidity detector is usually at the same level as the material, in the middle of the material outlet to the ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com