Device and method for preparing diffusion layer slurry of proton exchange membrane fuel cell

A proton exchange membrane and fuel cell technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of low cost and high mixing efficiency, achieve high mixing efficiency, wide application prospects, and solve temperature control problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

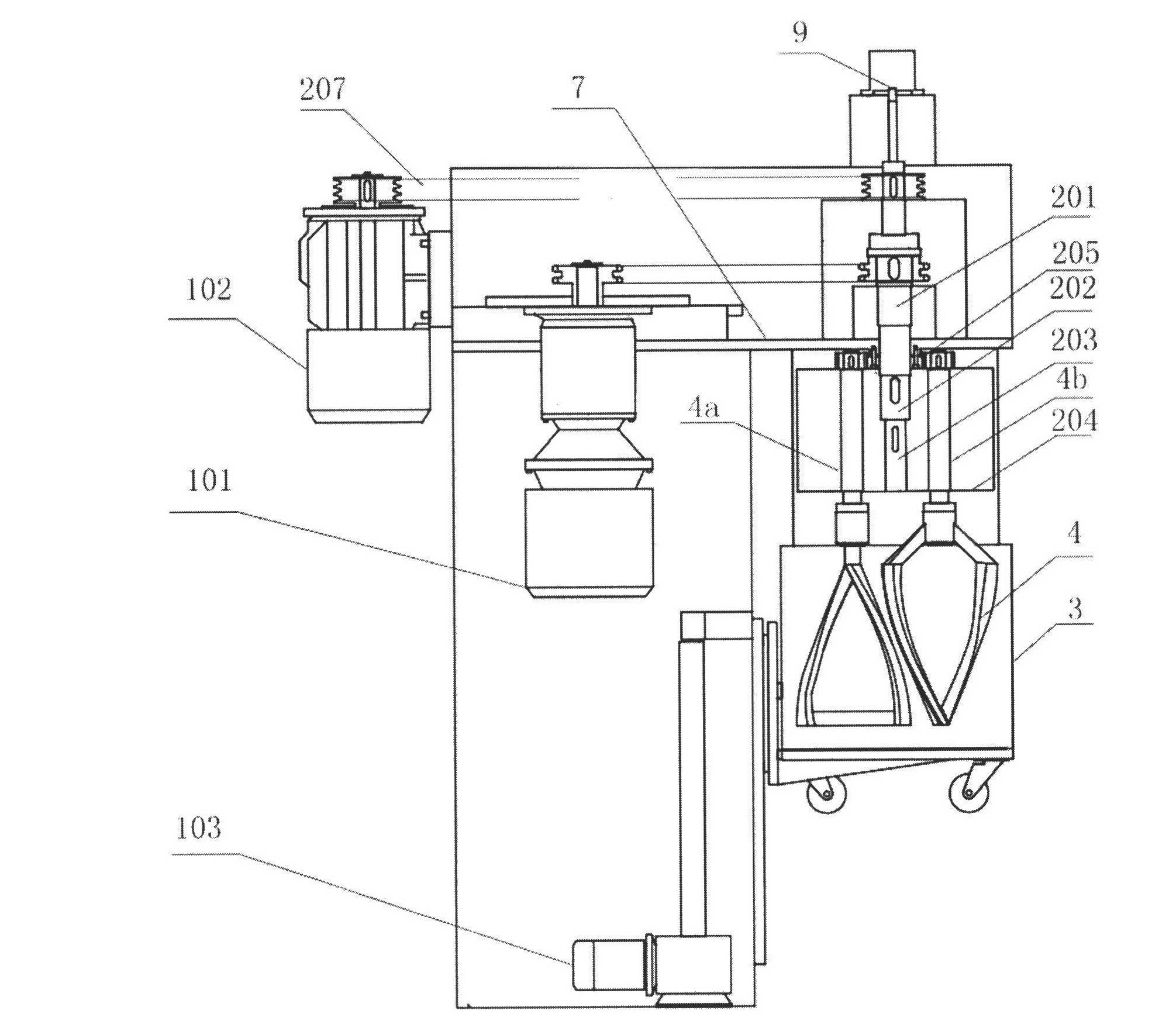

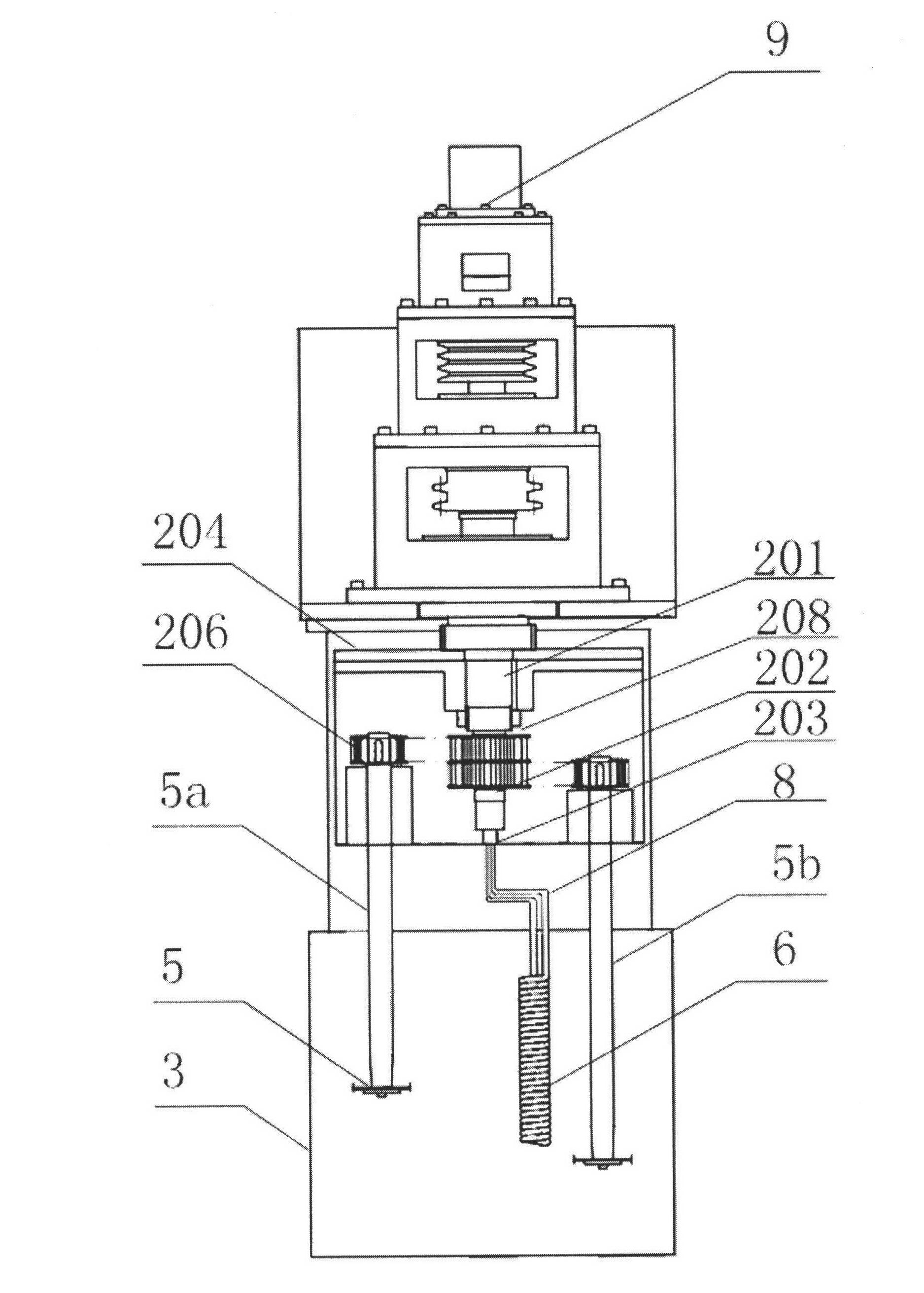

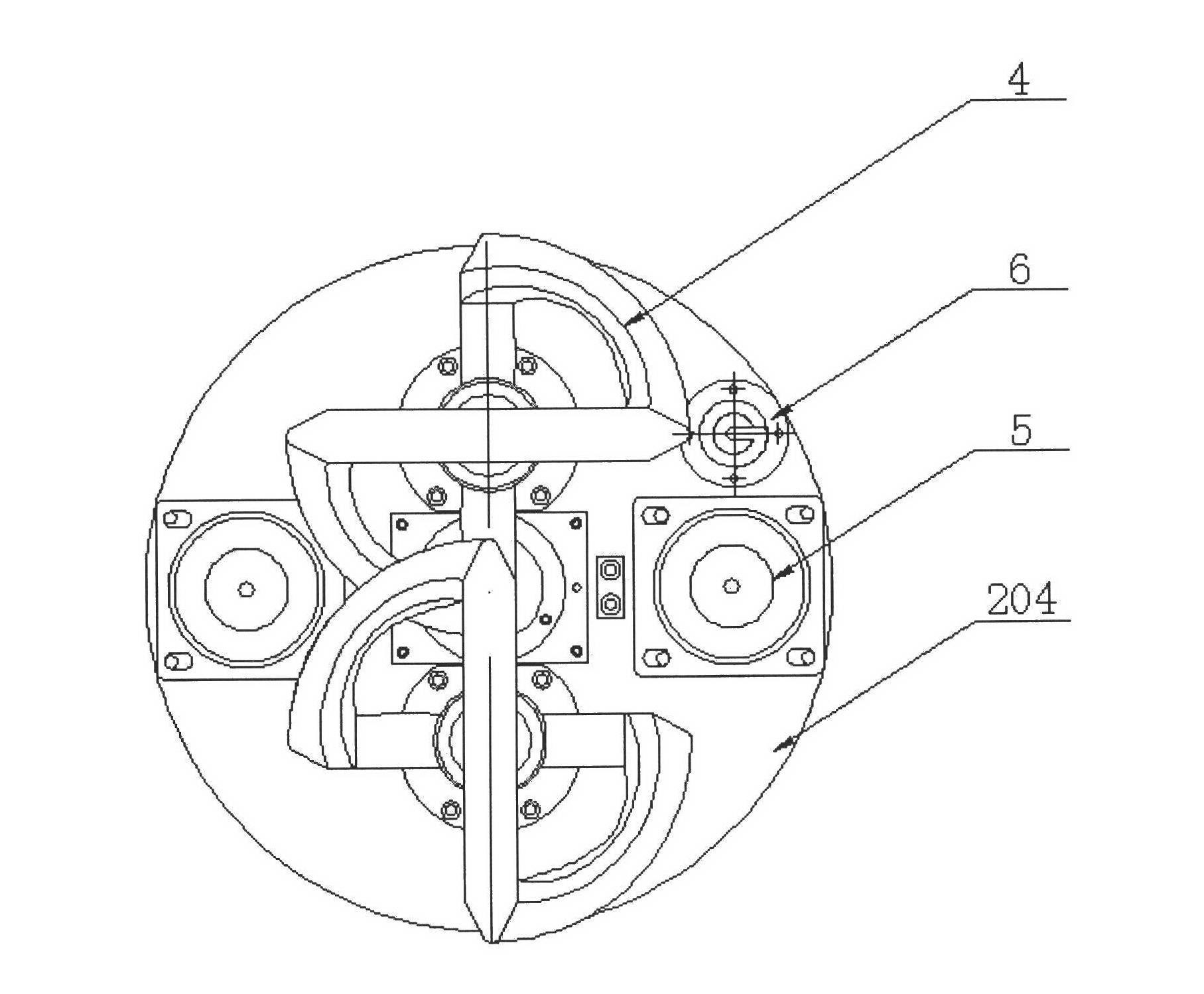

[0036] The two rotating shafts of the low-speed agitator are symmetrically installed on both sides of the 1 / 6d away from the center of the turret. The rotating shaft passes through the turret and meshes with the large gear fixed on the frame through the pinion gear. The transmission ratio is 1:2. The type of low-speed agitator is a twist frame, which can stir the slurry to the greatest extent. The two rotating shafts of the high-speed disperser are installed symmetrically on both sides 1 / 4d away from the center of the turret, perpendicular to the line connecting the center of the low-speed rotating shaft. 10cm. Two sets of internal cooling components are installed, which are symmetrically installed at 2 / 5d from the center of the turret, at a 60° angle to the low-speed rotation axis. The heat exchange tube is coil type, and the flow rate is 120L / h. The mixing tank is a jacketed structure with a volume of 30L and a slurry handling capacity of 20L.

[0037] Start the automatic ...

Embodiment 2

[0040] The two rotating shafts of the low-speed agitator are symmetrically installed on both sides of the 1 / 6d away from the center of the turret. The rotating shaft passes through the turret and meshes with the large gear fixed on the frame through the pinion gear. The transmission ratio is 1:2. The type of low-speed agitator is a twist frame, which can stir the slurry to the greatest extent. The two rotating shafts of the high-speed disperser are installed symmetrically on both sides 1 / 4d away from the center of the turret, perpendicular to the line connecting the center of the low-speed rotating shaft. 10cm. Two sets of internal cooling components are installed, which are symmetrically installed at 2 / 5d from the center of the turret, at a 60° angle to the low-speed rotation axis. The heat exchange tube is coil type, and the flow rate is 120L / h. The mixing tank is a jacketed structure with a volume of 40L and a slurry handling capacity of 30L.

[0041] Start the automatic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com